Factory wholesale Drone Frame - CNC machining carbon fiber parts cutting for drone – Feimoshi

Factory wholesale Drone Frame - CNC machining carbon fiber parts cutting for drone – Feimoshi Detail:

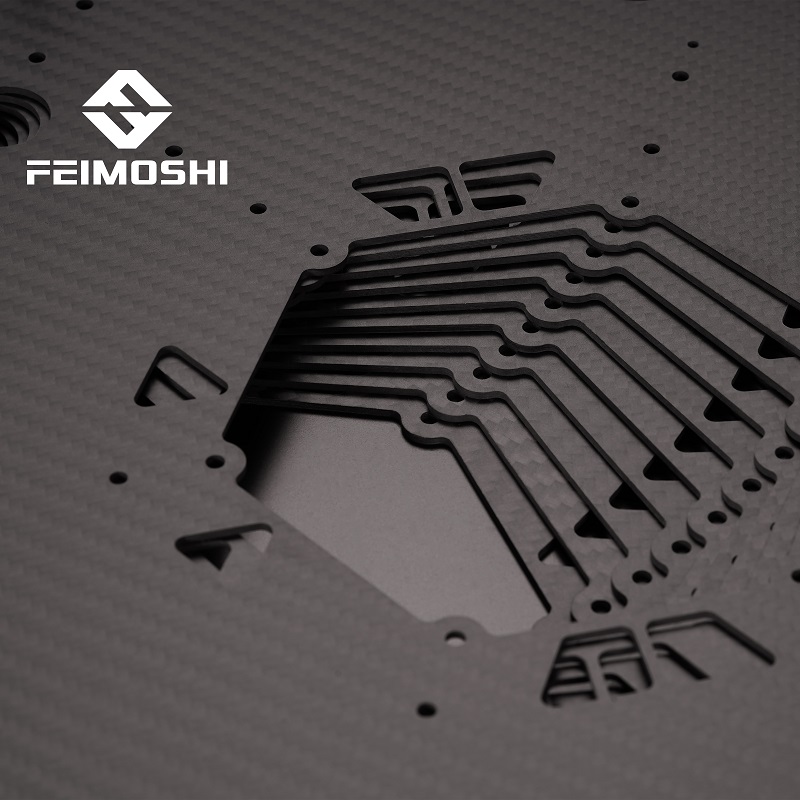

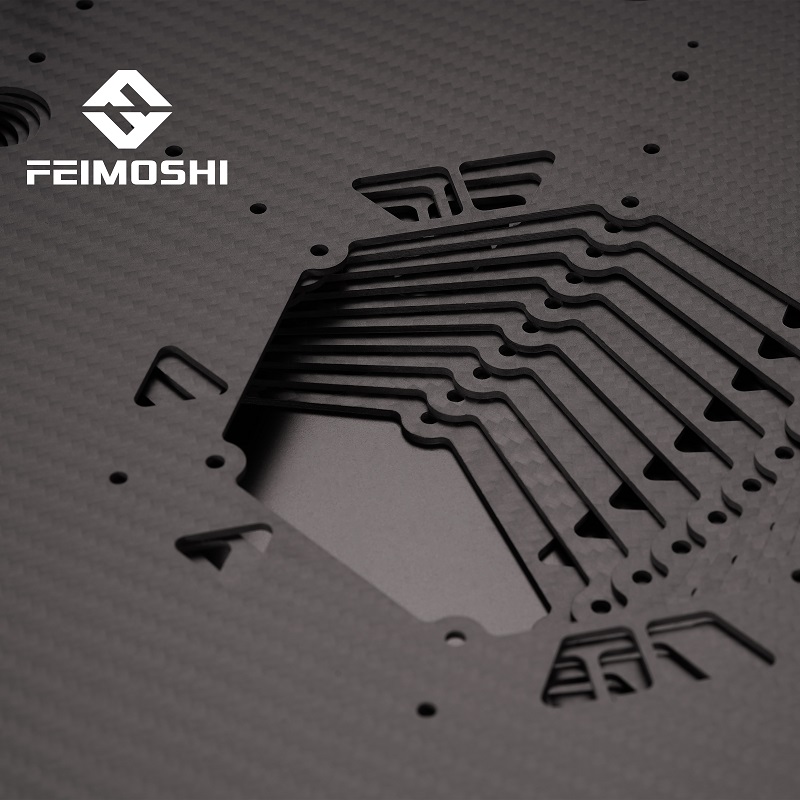

CNC machining carbon fiber parts cutting for drone

FEIMOSHI is a proffessional manufacturer of carbon fiber products, loved by drone customers and our CNC cutting process has won their praise. CNC machining is precision and cost-effective way to achieve innovation and creativity, which triggers out our endless imagination and creative inspiration. We had made so many different carbon fiber CNC parts for racing parts, RC helicopters, bicycle bracket, and reinforcements for 10 years.

Feature:

Surface: Matter/Light/Twill/plain

Size: OEM(STEP, DWG or other)

Material: 100% carbon fiber

Shape: Smooth

Technical: FPV/Drone/UAV/RC Frame

Applications:

1. Aerospace, Helicopters Model Drone ,UAVS, FPV

2. RC model parts

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. building construction repair and strengthening

Our service

Any needs, please feel free to contact me!

Express: Fedex, UPS, DHL, TNT

Delivery time: about 5-10 working days

After-sales service

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Factory wholesale Drone Frame - CNC machining carbon fiber parts cutting for drone – Feimoshi , The product will supply to all over the world, such as: French, South Korea, Turkey, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!