Free sample for Carbon Fiber Guitar Body - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi

Free sample for Carbon Fiber Guitar Body - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi Detail:

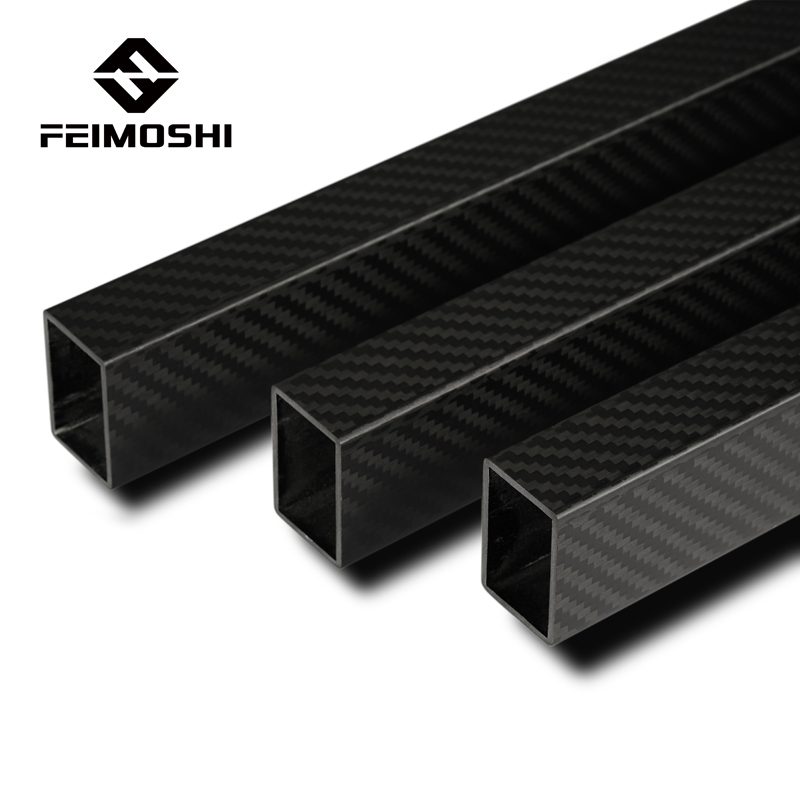

Custom Octagonal composite carbon fiber square tube for accessories

In these recent years, custom carbon fiber tube is more populare in the drone market.

Also we have carbon fiber round tube, carbon fiber octagonal tube and carbon fiber square tube in stock.

Different size and type is avaliable for your choosing.

Small carbon fiber round tube could be inserting the large carbon fiber tube according to your requirements.

Carbon fiber rectangle tube, large carbon fiber tubes, carbon fiber tube handguard, ect. are all customized according to your requirements.

If you have any other requirements, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

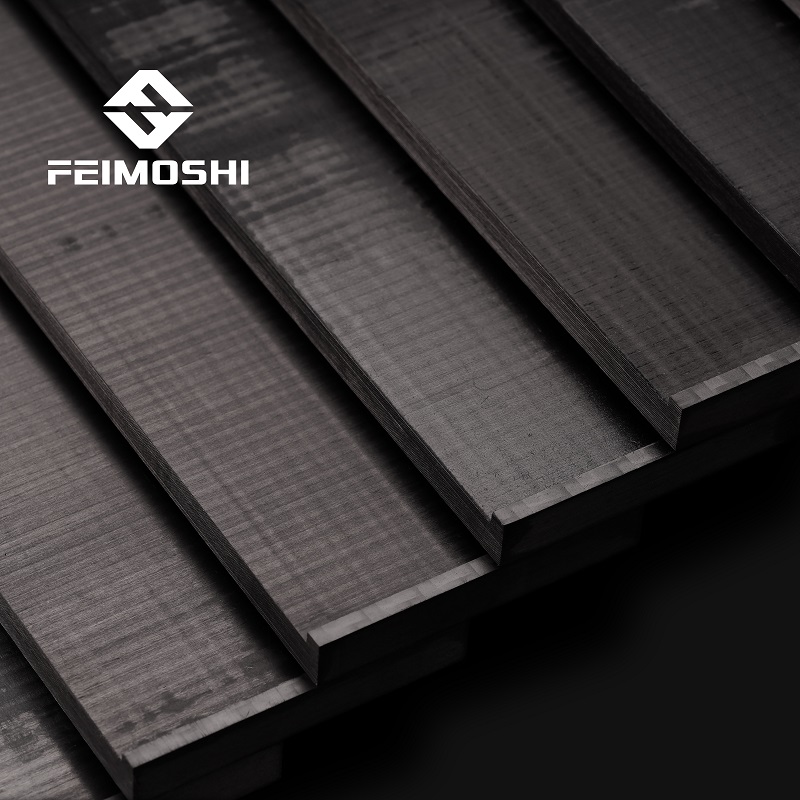

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. Free sample for Carbon Fiber Guitar Body - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi , The product will supply to all over the world, such as: Kyrgyzstan, Nepal, Namibia, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

Send your message to us:

Write your message here and send it to us