High definition Aluminum Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi

High definition Aluminum Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi Detail:

2.0mm Twill matte CNC carbon fiber composite cutting opener mount

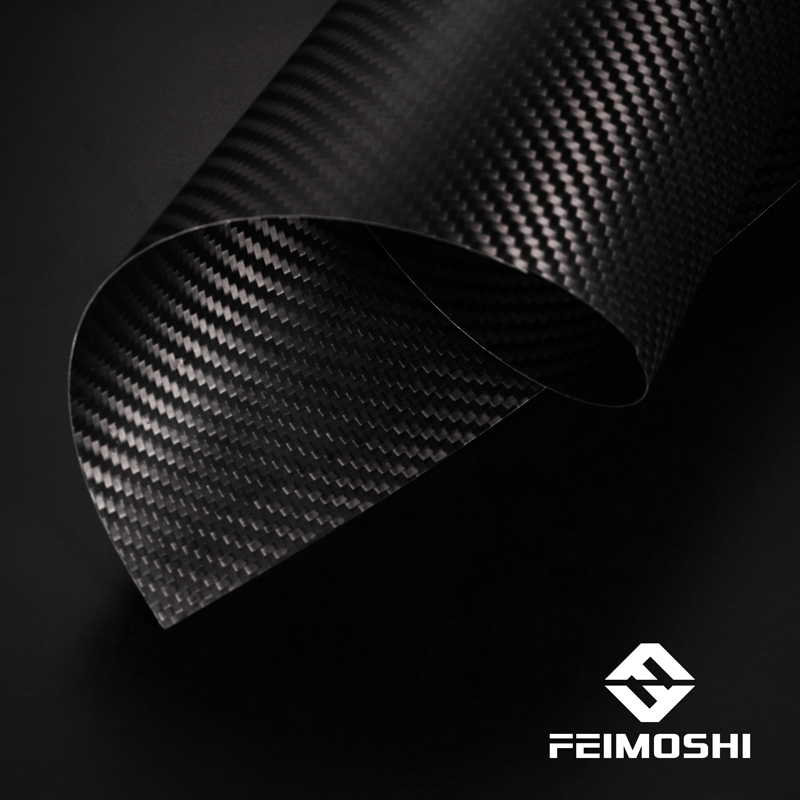

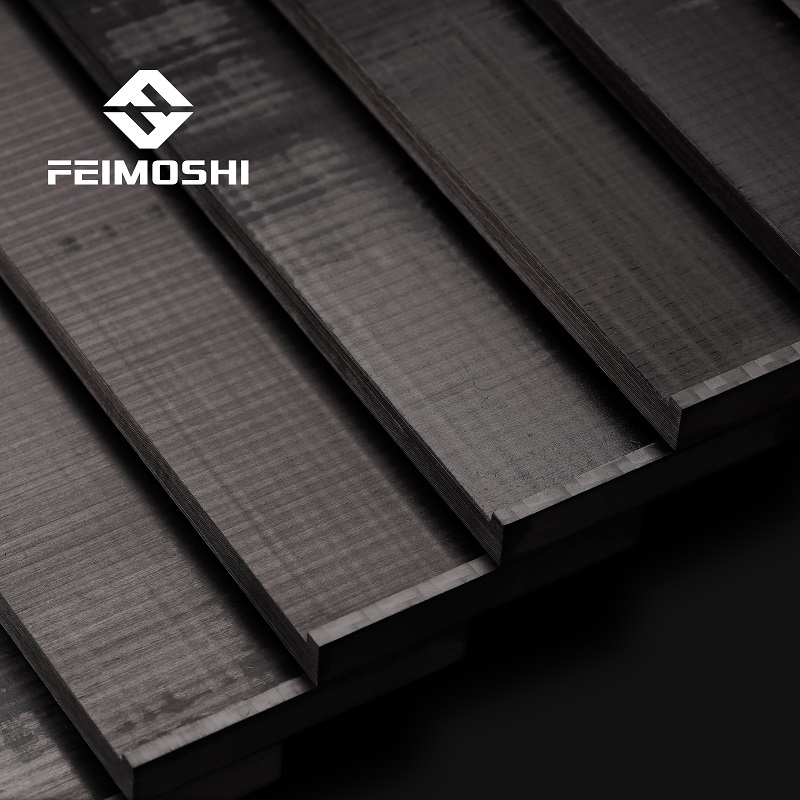

400X500X2.0mm and 500X600X2.0mm 3K twill matte carbon fiber plate could be cut to different types. 2.0mm thickness is very suitable for the carbon fiber opener. Normally, we could do some stocked quantity for 2.0mm thickness. Carbon fiber sheet is made of 3K twill matte cloth and UD cloth and epoxy resin.

CNC cutting service is ok for us. If you feel that the edge is very sharp, we could do the chamfer for the edge to make it more professional. Also wanting to connect the hardware with carbon fiber parts, contact us freely. Our engineer team will offer some good suggestions for your choosing.

Product detail pictures:

Related Product Guide:

4. Its maintenance function is good. Carbon fiber material is waterproof, resistant to high temperature, ultra-low temperature, and abrasion, and can be used in all harsh environments. High definition Aluminum Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi , The product will supply to all over the world, such as: France, Mauritania, Zurich, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

Send your message to us:

Write your message here and send it to us