High Quality Composite Sheet - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi

High Quality Composite Sheet - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi Detail:

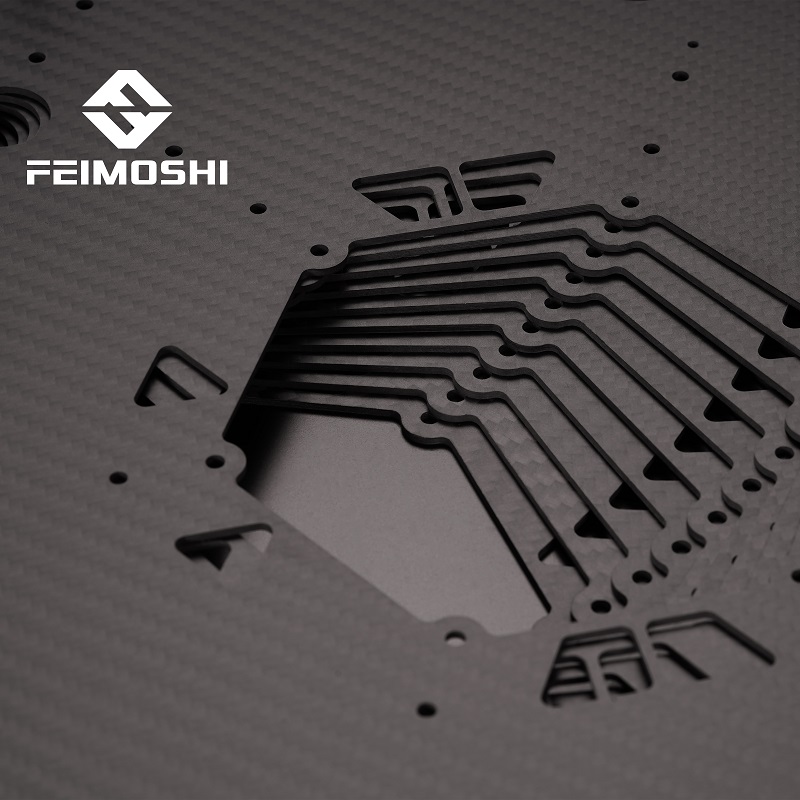

custom 20mm thick CNC cutting machine carbon fiber sheet for construction

Custom cutting machine Full Carbon Fiber Sheet have many advantage, Stiffer, stronger, and lighter than steel and aluminum, carbon fiber works miracles reinforcing materials and lifting many industries to new levels of performance.The future of carbon fiber is very bright, with vast potential in many different industries. So many advantages help to custom cutting machine. carbon fiber sheet quickly become the leader of the drone market, widely use in the uav and fpv market. If any need of custom cutting machine carbon fiber sheet, please feel free to contact us.

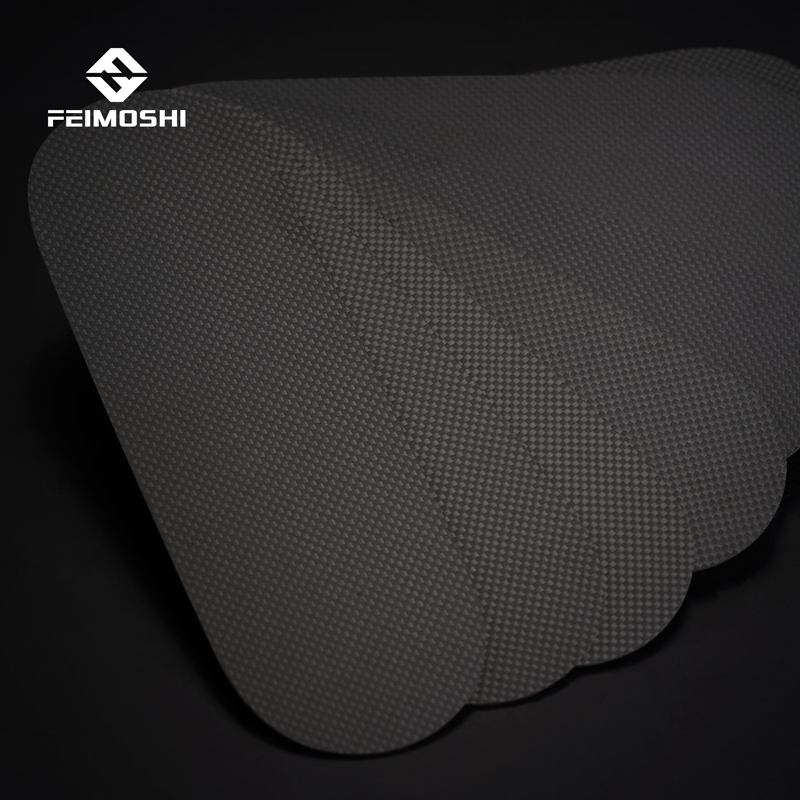

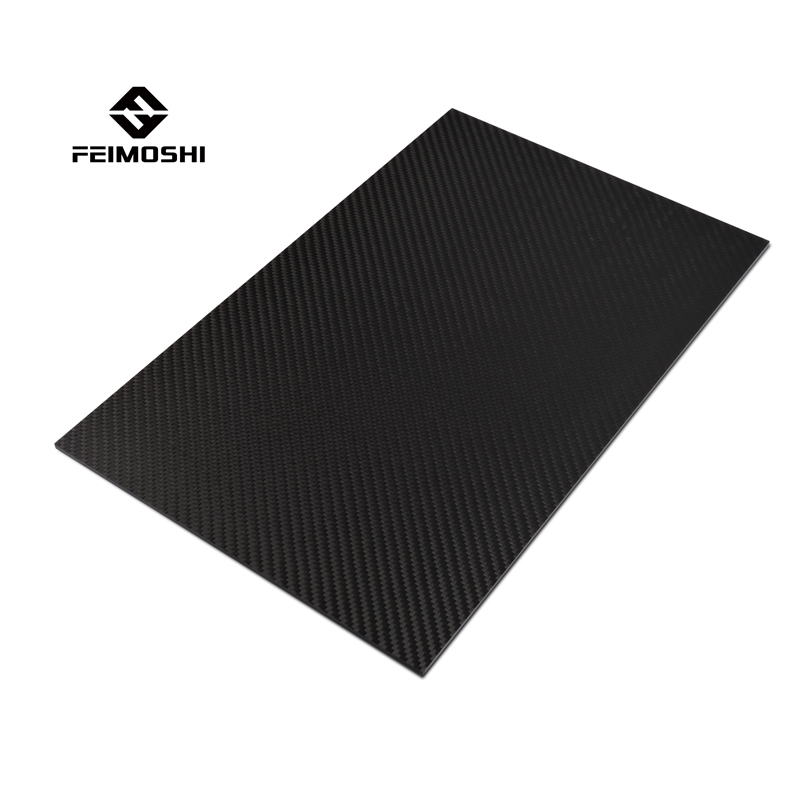

Surface: 3K twill matte

Finish: matte or glossy in both sides, twill or plain weave

Stock: twill matte 0.5-10.0mm pure carbon fiber plates in stock

Service: OEM & ODM and CNC services, Logo Service,Carbon Fiber CNC Cutting

FAQ

1) Do you produce the thick carbon fiber sheet?

Yes, 20.0mm, 30.0mm thick carbon fiber sheet is ok for us.

2) Can you do the countersunk or chamfer on carbon fiber material?

Yes, countersunk could help to reduce the weight and do the logo on carbon fiber sheet. Carbon fiber chamfer could make the edge round and smooth.

3) Do you offer the cutting service?

Yes, CNC cutting is ok according to your drawings. We will make the quotation according to the drawings’ comprehensive.

4) MOQ requirements?

Normally, one 400X500mm plate or 500X600mm plate for cutting is fine.

5) How many days do you need for the cutting?

Normally, it needs about 7-10 working days for cutting.

Looking for ideal Carbon Fiber Sheet Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Cutting are quality guaranteed. We are China Origin Factory of Custom Cutting Machine Carbon Fiber Sheet. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

At present, the carbon fiber industry is in a period of explosive growth, and the growth rate of the carbon fiber demand market will remain at around 17% in the future. High Quality Composite Sheet - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi , The product will supply to all over the world, such as: Rotterdam, Switzerland, Wellington, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.