High Quality Composite Sheet - OEM service custom carbon fiber cnc cutting – Feimoshi

High Quality Composite Sheet - OEM service custom carbon fiber cnc cutting – Feimoshi Detail:

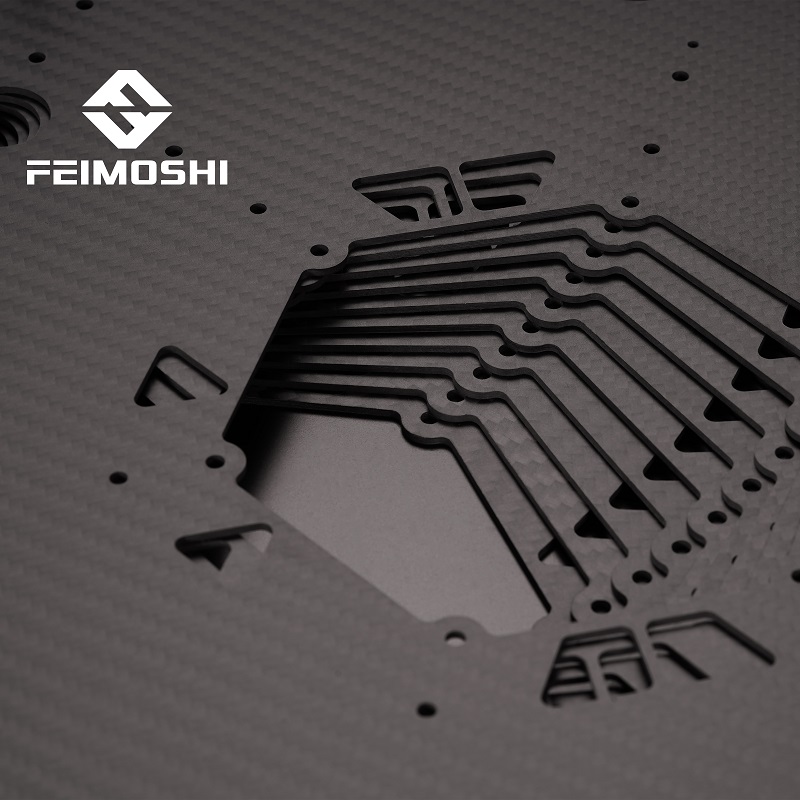

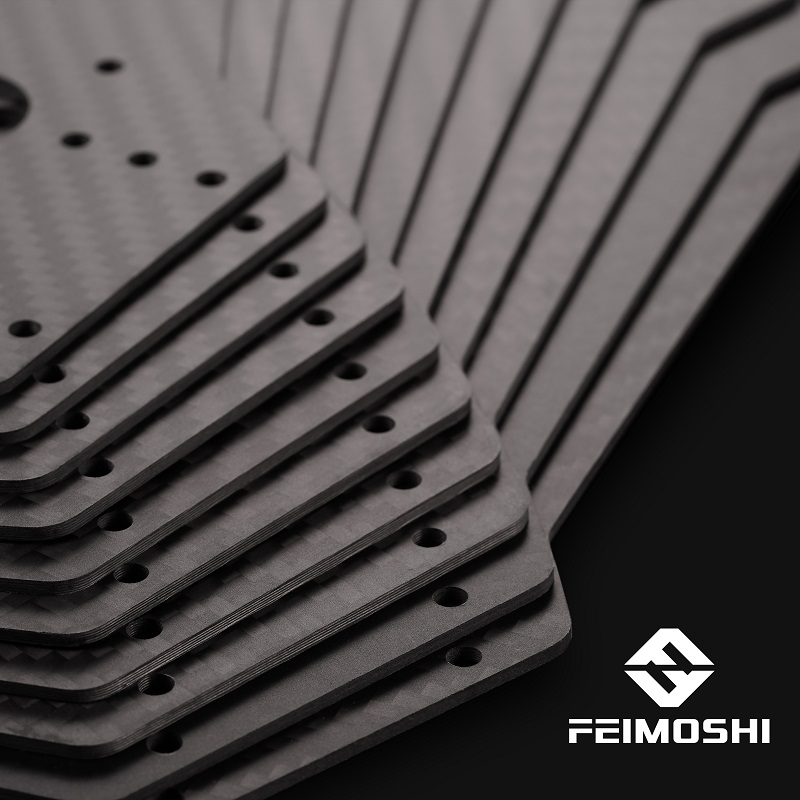

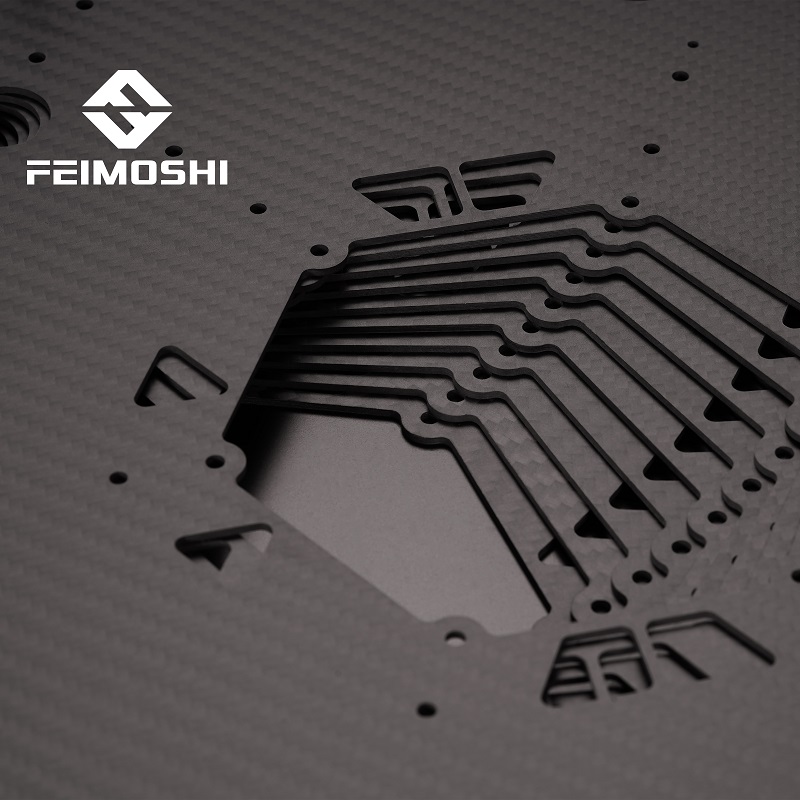

OEM service custom carbon fiber cnc cutting

Carbon fiber plates come in so many variations to fit a wide range of applications. A standard carbon fiber plate is an excellent replacement for aluminum plates when you need something lightweight and strong.

Carbon fiber plate comes in thicknesses from 0.040” (1mm) up to 1.00” (25.4mm) to fit nearly any application. Standard twill and plain weave plates are excellent choices for replacing aluminum or steel.

Material: carbon fiber frame part

Size: Customized (welcome to customized)

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plates are in stock

Service: OEM & ODM, Cnc Cutting Service, And Logo Printing

Other Service: Packing and assembly service

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is the Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for tesing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing

Product detail pictures:

Related Product Guide:

When it comes to carbon fiber, you should know something! Known as the "king of new materials" and "black gold", the new material has the advantages of light weight, high strength, high temperature resistance and corrosion resistance. With the development of life, it has been applied in more and more fields.So what carbon fiber products will we be familiar with but unfamiliar with in our daily life?1. In the automobile industry, carbon fiber also plays an important role. Nowadays, automobiles pay more and more attention to energy saving and emission reduction, and the realization of energy saving and emission reduction is mainly due to the lightweight structure. Therefore, some auto parts are now made of carbon fiber materials. Thereby achieving the effect of weight loss.2. In sports goods, such as bicycles, scooters, racing cars and other sports goods can be made of carbon fiber materials.3. On jewelry, carbon fiber can be used to make wallets and glasses.4.On tools, carbon fiber ruler, carbon fiber saber, etc. High Quality Composite Sheet - OEM service custom carbon fiber cnc cutting – Feimoshi , The product will supply to all over the world, such as: Sri Lanka, Nigeria, South Korea, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.