High Quality Cutting Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi

High Quality Cutting Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi Detail:

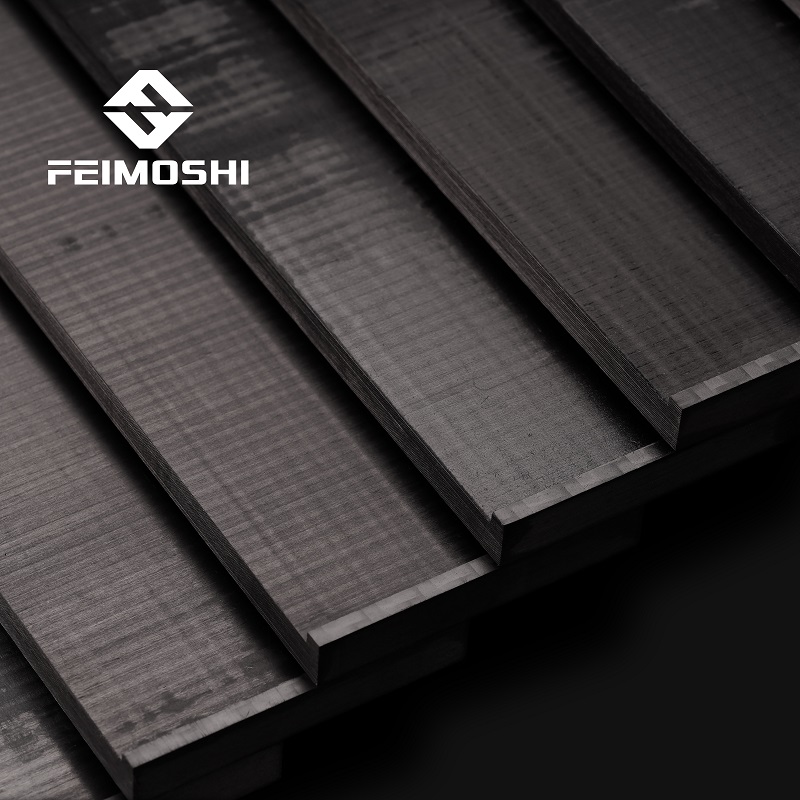

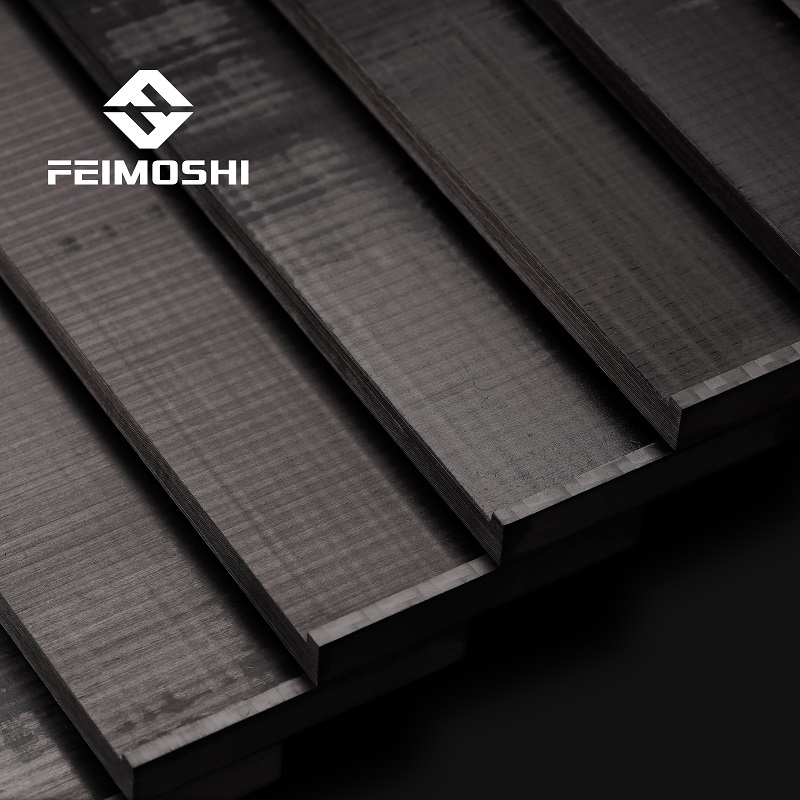

2.0mm Twill matte CNC carbon fiber composite cutting opener mount

400X500X2.0mm and 500X600X2.0mm 3K twill matte carbon fiber plate could be cut to different types. 2.0mm thickness is very suitable for the carbon fiber opener. Normally, we could do some stocked quantity for 2.0mm thickness. Carbon fiber sheet is made of 3K twill matte cloth and UD cloth and epoxy resin.

CNC cutting service is ok for us. If you feel that the edge is very sharp, we could do the chamfer for the edge to make it more professional. Also wanting to connect the hardware with carbon fiber parts, contact us freely. Our engineer team will offer some good suggestions for your choosing.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. High Quality Cutting Composite - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi , The product will supply to all over the world, such as: Sacramento, Netherlands, Adelaide, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

Send your message to us:

Write your message here and send it to us