High Quality Cutting Composite - 3K Carbon Plate Shape for RC racing parts – Feimoshi

High Quality Cutting Composite - 3K Carbon Plate Shape for RC racing parts – Feimoshi Detail:

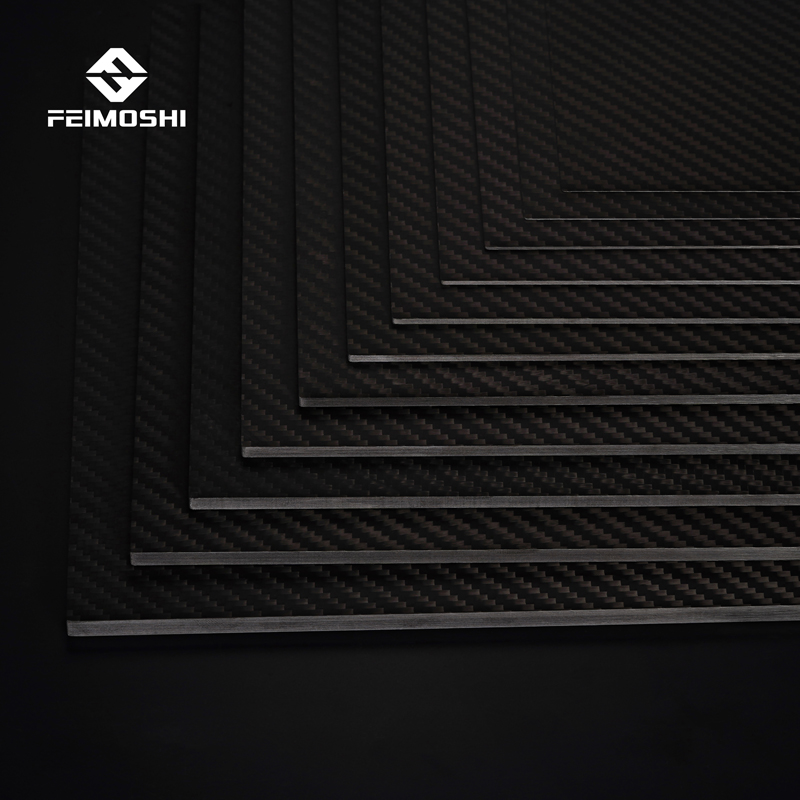

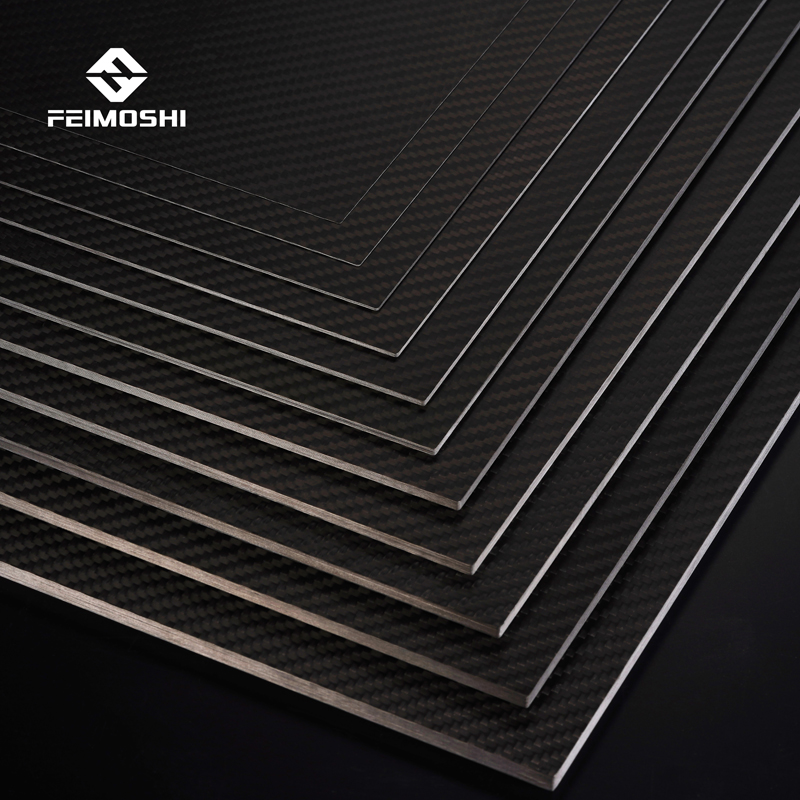

3K Carbon Plate Shape for RC racing parts

Below are advantages for CNC machining :

(1) A large amount of reduction in the number of the tooling, and the complex parts of the parts do not require complex tooling. If we want to change the shape and size of the parts, it is only necessary to modify the processing program for the parts, and it is suitable for the development and modification of the new products.

(2) The machining quality is stable, the machining precision is high, and the repetition precision is high, which is suitable for the processing requirements of the aircraft.

(3) The production efficiency is high under the condition of multi variety and small batch production, it can reduce the time of production preparation, machine adjustment and process inspection, and the cutting time is reduced by using the best cutting volume. We also support 4 Axis Cnc Cutting carbon Fiber Tube drilling High-Strength carbon Fiber Pipes use in building construction

FAQ

1) Could you do the CNC cutting?

Yes, we could do the CNC cutting for the carbon fiber material.

2) what is the formate of the drawings you need?

DXF, DWG and step formate are all fine.

3) What is the tolerance of CNC cutting?

About +/-0.2mm

4) What is the largest carbon fiber sheet for cutting?

1000X2500mm cutting is ok for us.

5) How many days for the cutting service?

Normally, it needs about 7-15 working days and it also depends on the order quantity.

Looking for ideal Carbon Fiber FPV Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Hobby Carbon Fiber are quality guaranteed. We are China Origin Factory of Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. High Quality Cutting Composite - 3K Carbon Plate Shape for RC racing parts – Feimoshi , The product will supply to all over the world, such as: Lyon, Moldova, Oman, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.