Hot New Products Carbon Fiber Plate Keyboard - custom carbon fiber parts by CNC cutting – Feimoshi

Hot New Products Carbon Fiber Plate Keyboard - custom carbon fiber parts by CNC cutting – Feimoshi Detail:

Description:

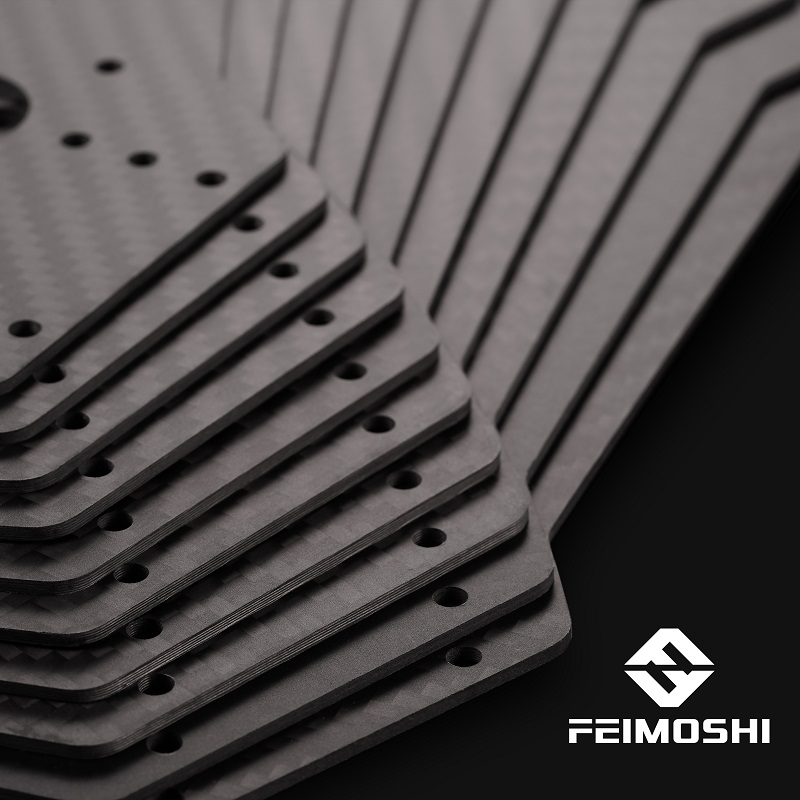

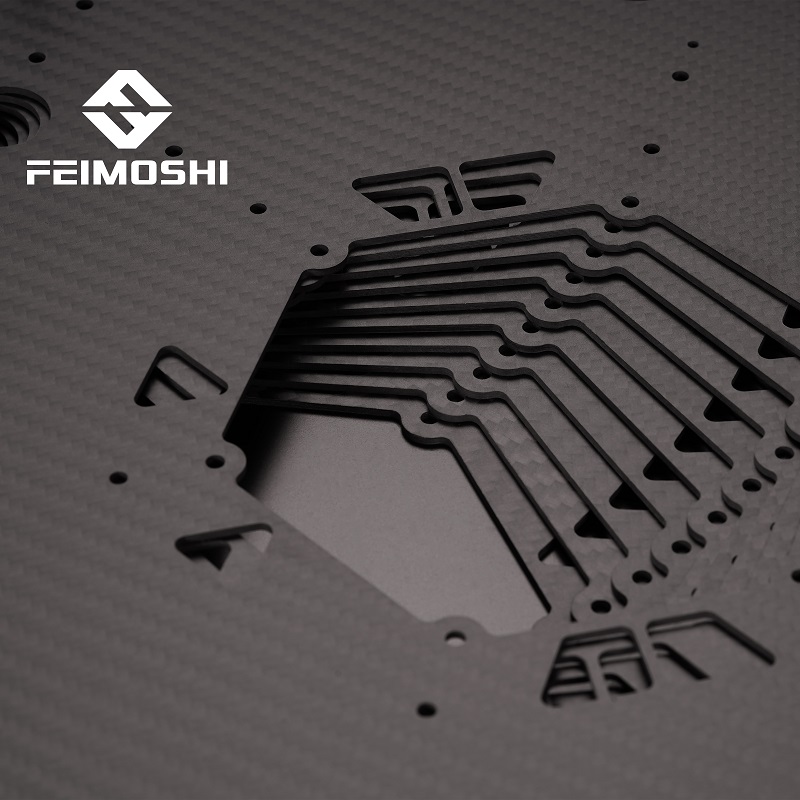

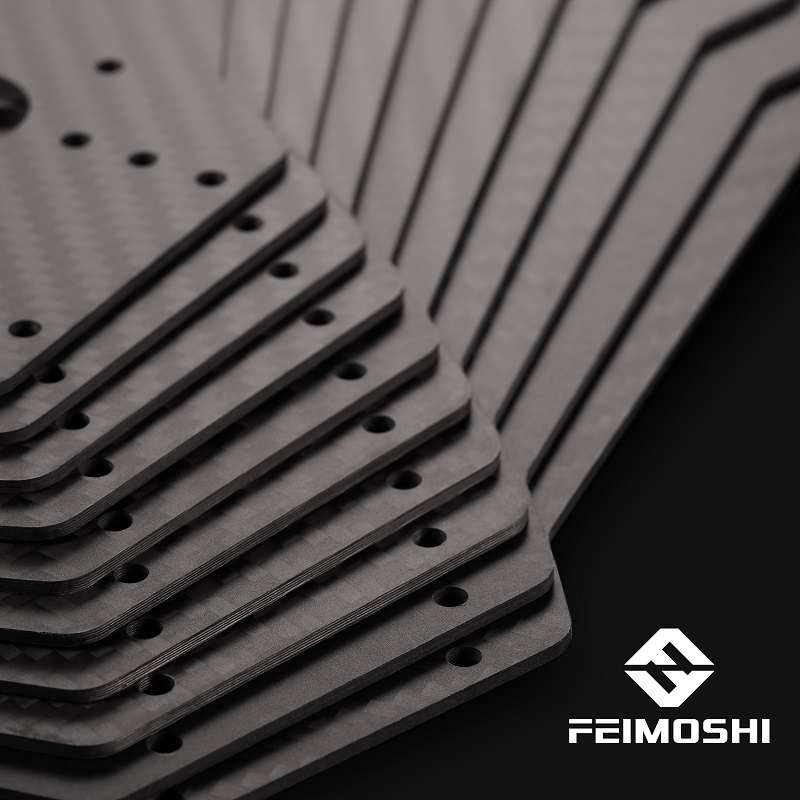

Cnc Carbon Fiber Cutting parts are made of carbon fiber plate through CNC machining. Compared with other materials, carbon fiber has more outstanding features, such as high strength, light weight, anti-aging, it’s widely used in different fields. We supply customized carbon fiber CNC machining service according to your drawings.

CNC service:

We are professional in carbon fiber plates and carbon fiber sheets CNC cutting for Drones /FPV for more than 10 years

We have been cooperating with lots of famous brand.

We do cutting according to our customers’ design(file with .dxf format) and we protect each design for our customers.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Hot New Products Carbon Fiber Plate Keyboard - custom carbon fiber parts by CNC cutting – Feimoshi , The product will supply to all over the world, such as: Costa Rica, Portland, Vietnam, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Send your message to us:

Write your message here and send it to us