Hot sale Blue Carbon Fiber Plate - OEM manufacturer custom cnc carbon fiber parts – Feimoshi

Hot sale Blue Carbon Fiber Plate - OEM manufacturer custom cnc carbon fiber parts – Feimoshi Detail:

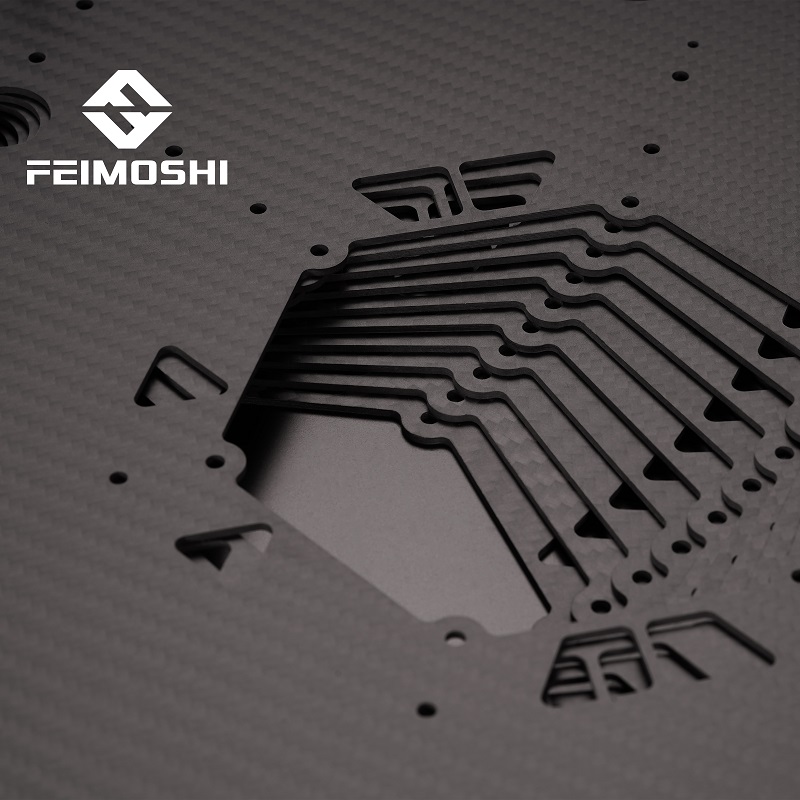

OEM manufacturer custom cnc carbon fiber parts

1. Base

CNC Machined Carbon Fiber Sheet parts is the mainstream environmental friendly new product of the century, it features high strength, abrasion resistant, weather-proof, waterproof, air-pervious.

2. Description

Features:

1. Very light and very strong.

2. Excellent durance.

3. Corrosion resistance.

4. Excellent planeness

5. Very flexible.

6. Nice appearance.

Application:

1. UAV, RC Toy model , Aeromodelling, Helicopter Model.

2. Electrical products.

3. Shipbuilding.

4. Space aviation defense.

5. Sports equipments.

6. Automobile parts.

7. Wind power blades.

8. Spinning Reels Brake Rotor friction plate, Rocker.

9.Medical device(X-ray, DR).

10. Etc.

FAQ

1) Could you do the CNC cutting?

Yes, we could do the CNC cutting for the carbon fiber material.

2) what is the format of the drawings you need?

DXF, DWG and step format are all fine.

3) What is the tolerance of CNC cutting?

About +/-0.2mm

4) What is the largest carbon fiber sheet for cutting?

1000X2500mm cutting is ok for us.

5) How many days for the cutting service?

Normally, it needs about 7-15 working days and it also depends on the order quantity.

Looking for ideal Carbon Fiber FPV Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Hobby Carbon Fiber are quality guaranteed. We are China Origin Factory of Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Hot sale Blue Carbon Fiber Plate - OEM manufacturer custom cnc carbon fiber parts – Feimoshi , The product will supply to all over the world, such as: Zimbabwe, Florida, Jersey, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.