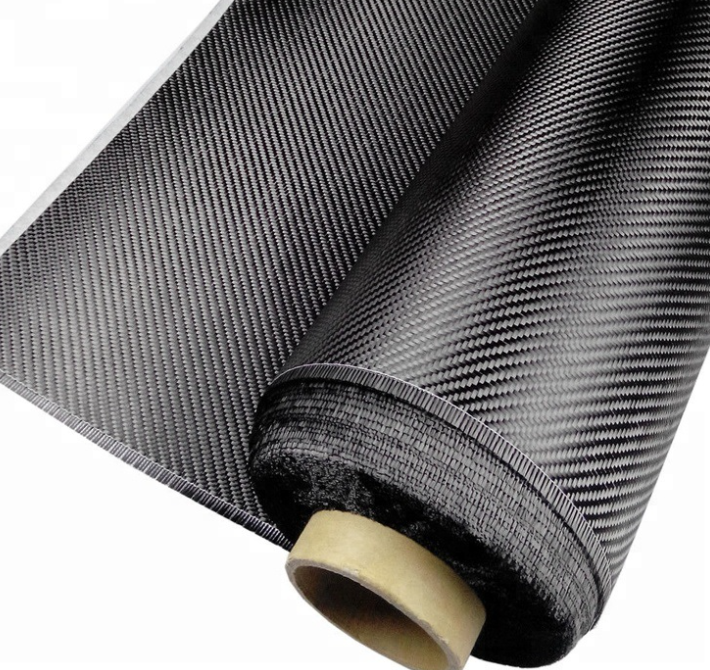

Hot sale Composite Rc Frame - 3K twill matte 200g prepreg carbon fiber cloth – Feimoshi

Hot sale Composite Rc Frame - 3K twill matte 200g prepreg carbon fiber cloth – Feimoshi Detail:

Carbon fiber cloth is woven from carbon fiber unidirectional, plain or twill weave.

The carbon fiber we use has high strength-to-weight ratio and stiffness-to-weight ratio.

Carbon fiber has thermal and electrical conductivity, and has excellent fatigue resistance.

Because of these high-quality characteristics, carbon fiber products are widely used in drones, military, medical industry and industry.

If properly designed, carbon fiber fabric composites can achieve the strength and rigidity of metals while significantly reducing weight.

Carbon fiber fabrics are compatible with various resin systems, including epoxy, polyester and vinyl ester resins.

Our company produces various thicknesses of carbon fiber boards and carbon fiber tubes through carbon fiber cloth, and customizes various special-shaped carbon fiber accessories for customers.

Our design team can also help customers to match between accessories and accessories.

These services have brought more respectable, faster and more competitive products to our customers.

Product detail pictures:

Related Product Guide:

Carbon fibers are generally not used alone, but in the form of composite materials. Composite material refers to a new type of material with certain special functions and structures formed by combining two or more materials. The material composition can be generally understood as matrix material + reinforcement material, among which the matrix material is mostly resin, ceramic, metal, Rubber and other materials, the reinforcing material is often glass fiber or carbon fiber. Hot sale Composite Rc Frame - 3K twill matte 200g prepreg carbon fiber cloth – Feimoshi , The product will supply to all over the world, such as: Lyon, Italy, USA, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!