OEM/ODM China Composite Frame - CNC cutting twill matte carbon fiber rc car chassis part – Feimoshi

OEM/ODM China Composite Frame - CNC cutting twill matte carbon fiber rc car chassis part – Feimoshi Detail:

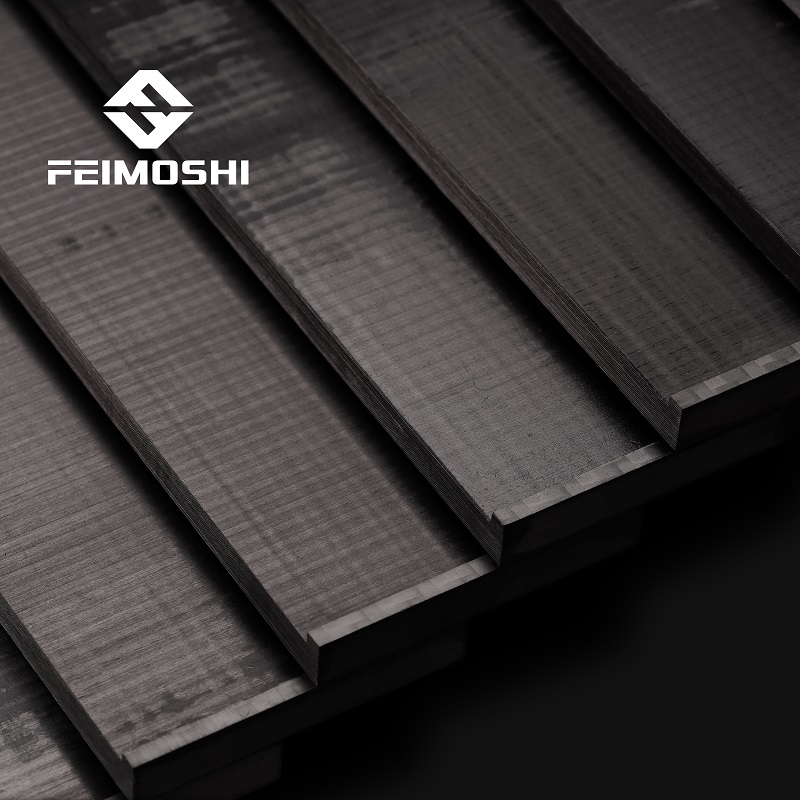

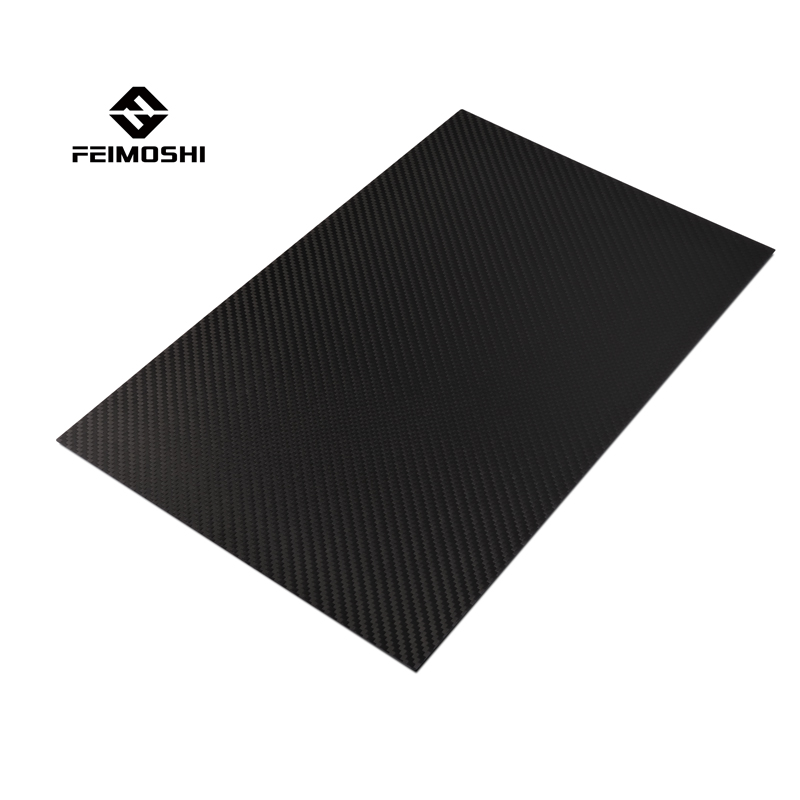

CNC cutting twill matte carbon fiber rc car chassis part

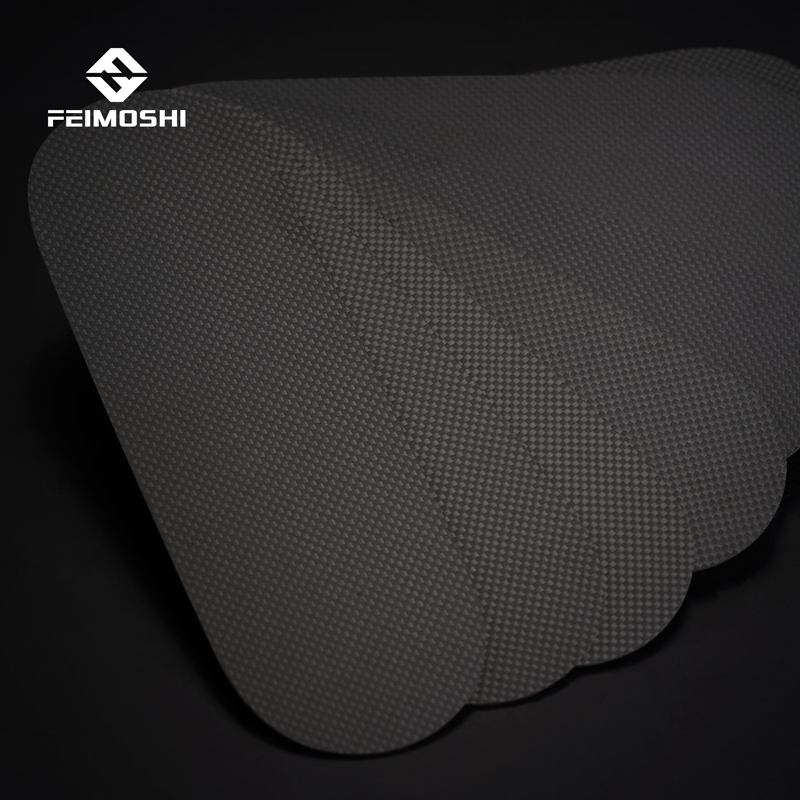

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

More quantity, more competitive price for your FPV frame.

Material: carbon fiber rc car chassis part

Size: Customized (welcome to customeied)

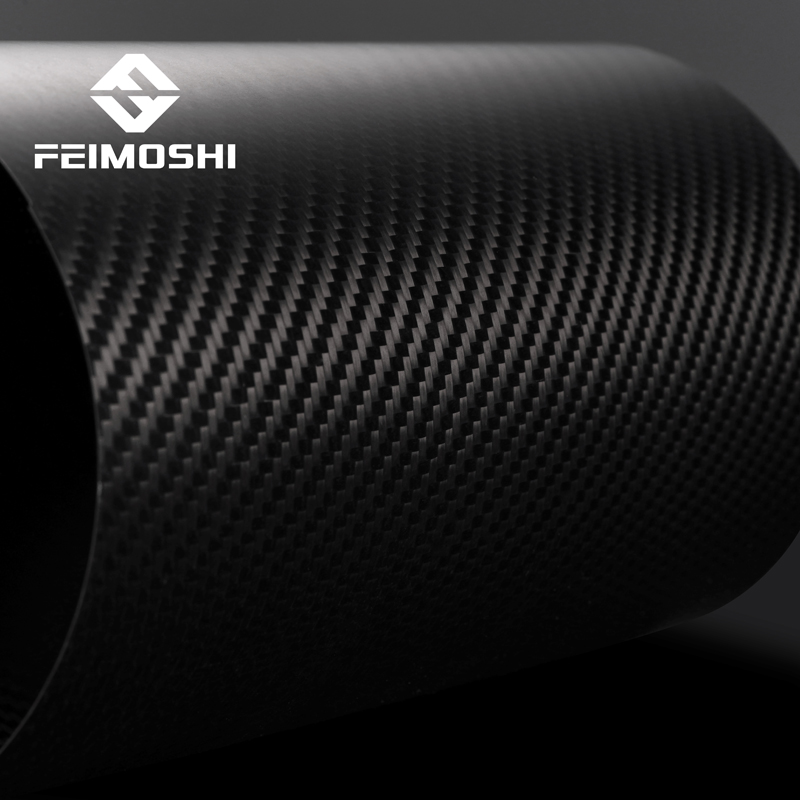

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plate are in stock

Service: OEM & ODM, Cnc Cutting Service And Logo Printing

Other Service: Packing and assembly service

Looking for ideal CNC 3K Carbon Fiber Sheet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 3K Carbon Fiber Sheet Plate are quality guaranteed. We are China Origin Factory of CNC Cutting Carbon Fiber Sheets. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

After data comparison, it is obvious that there is a gap between the mechanical properties of carbon fiber and carbon fiber composite materials, but even so, the carbon fiber pipe made of carbon fiber composite material far exceeds the pressure bearing capacity of steel pipe. OEM/ODM China Composite Frame - CNC cutting twill matte carbon fiber rc car chassis part – Feimoshi , The product will supply to all over the world, such as: Armenia, Ecuador, Croatia, The surface of the wound carbon fiber prepreg must be coated with a layer of OPP, and then the wound carbon fiber tube is sent to a high-temperature curing furnace to dry and form, and finally the mold is released, and the unstable parts on both sides are cut off to carry out production and processing solutions.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.