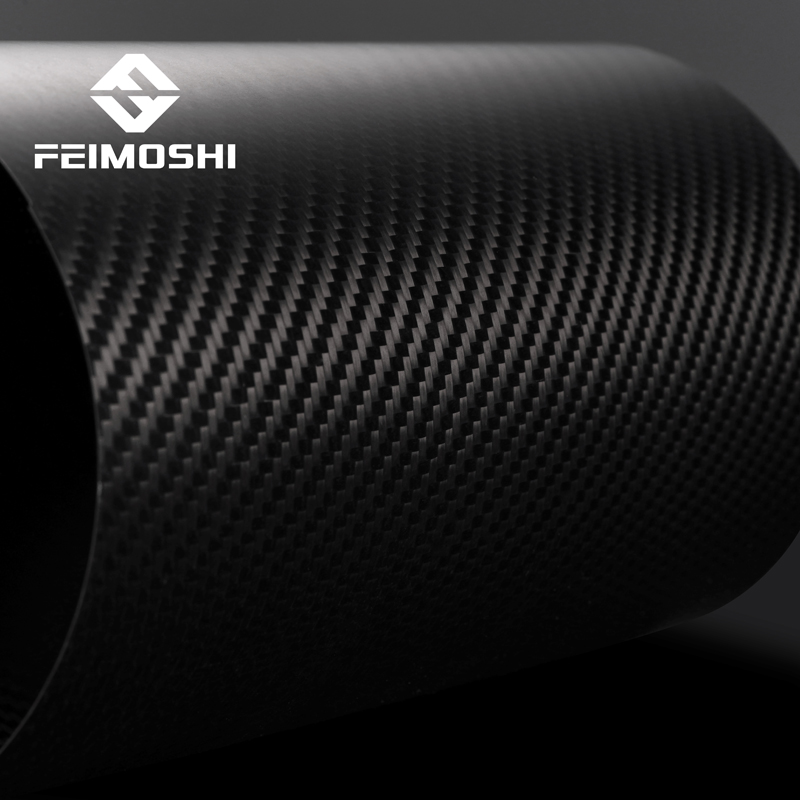

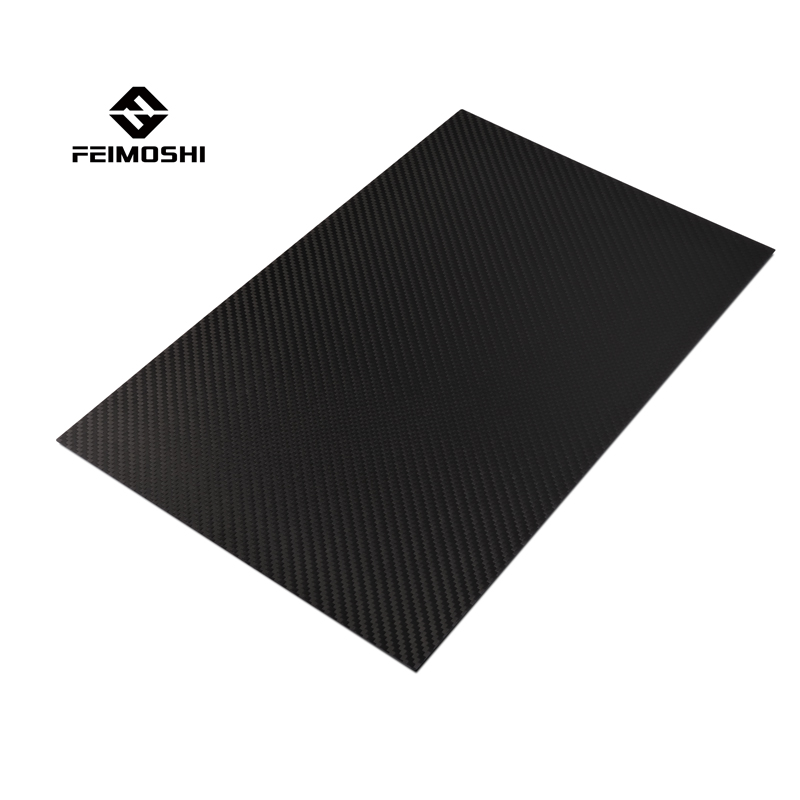

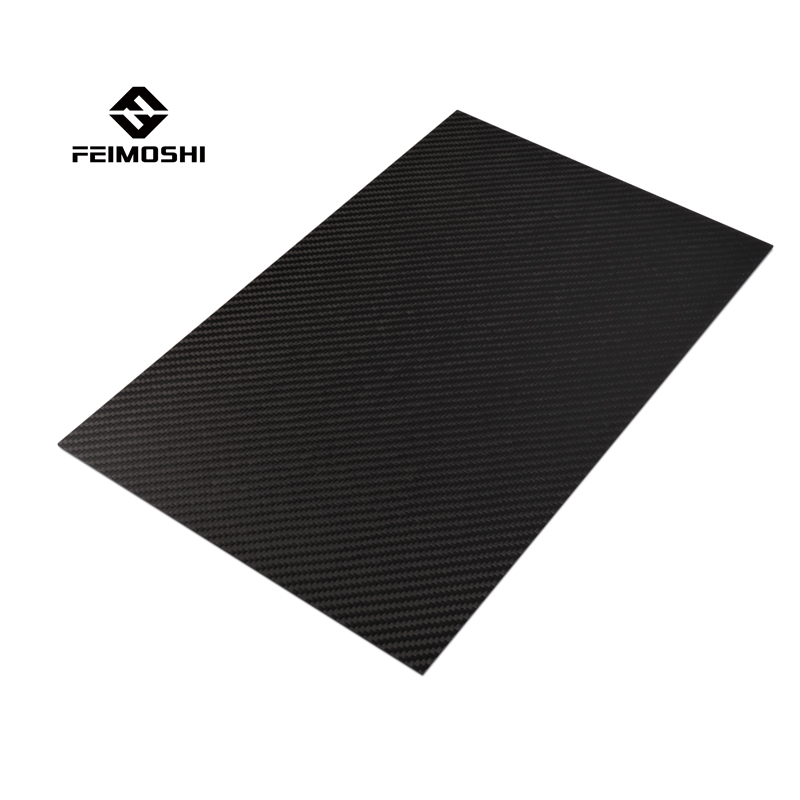

Professional China Composite Plate - High quality 3K twill matte carbon fiber plate – Feimoshi

Professional China Composite Plate - High quality 3K twill matte carbon fiber plate – Feimoshi Detail:

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Professional China Composite Plate - High quality 3K twill matte carbon fiber plate – Feimoshi , The product will supply to all over the world, such as: Brazil, Miami, Paris, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Send your message to us:

Write your message here and send it to us