OEM/ODM China Flat Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi

OEM/ODM China Flat Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi Detail:

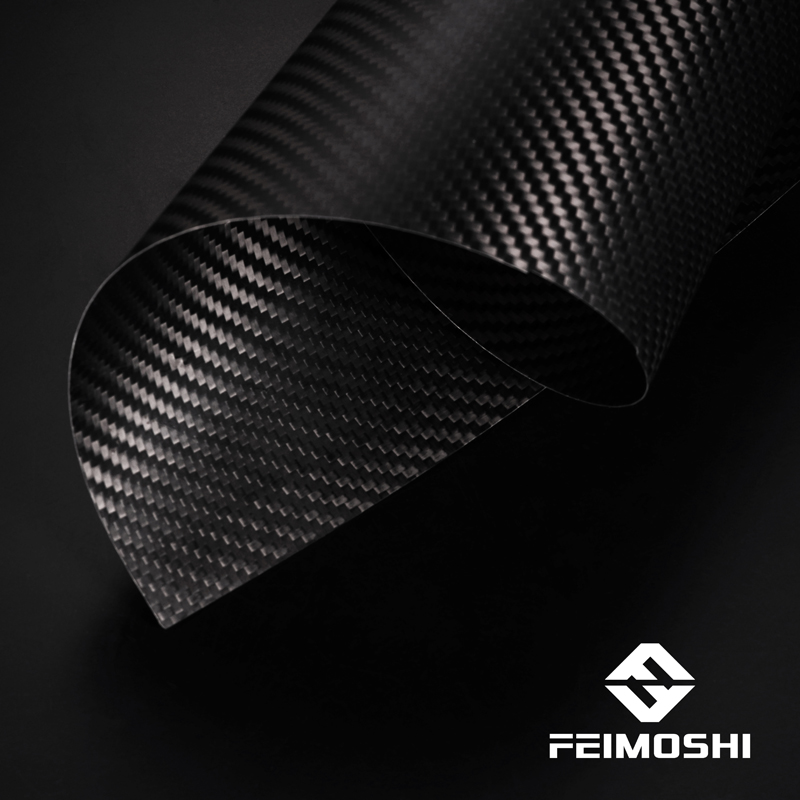

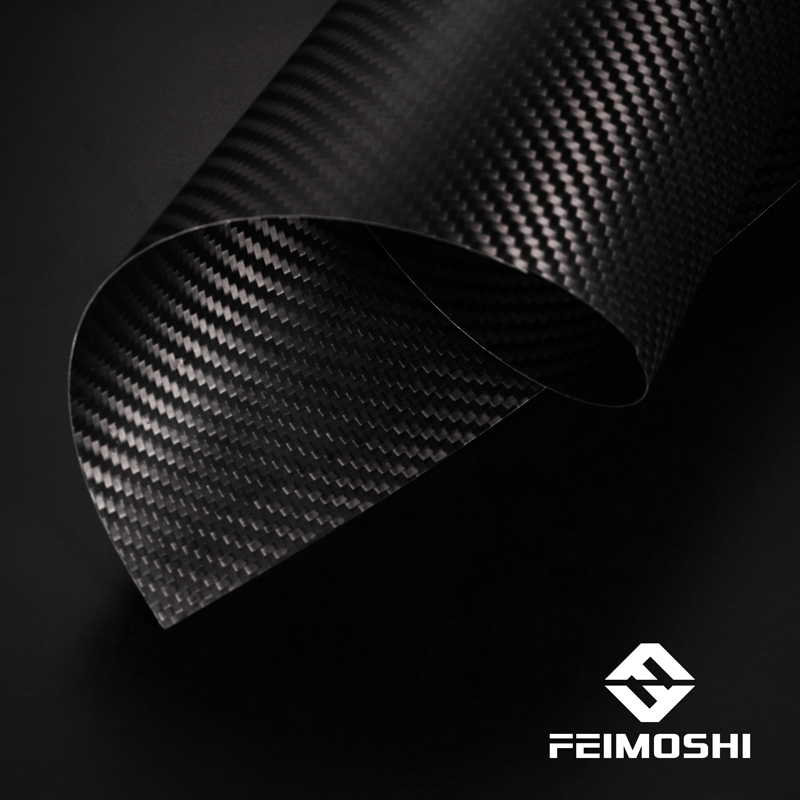

0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet

Carbon fiber is a new kind of high strength and high modulus fiber material with more than 95% carbon content.

Carbon fibers are flexible and rigid with outstanding mechanical performance.

The tensile strength of carbon fibers is several times that of steel.

Carbon fiber has 0.2mm-30mm thickness and 0.2-0.5mm thick plate is rigid and flexiable. And it could make the customers more creative.

You could inform me your ideal and we will help you to make it come true.

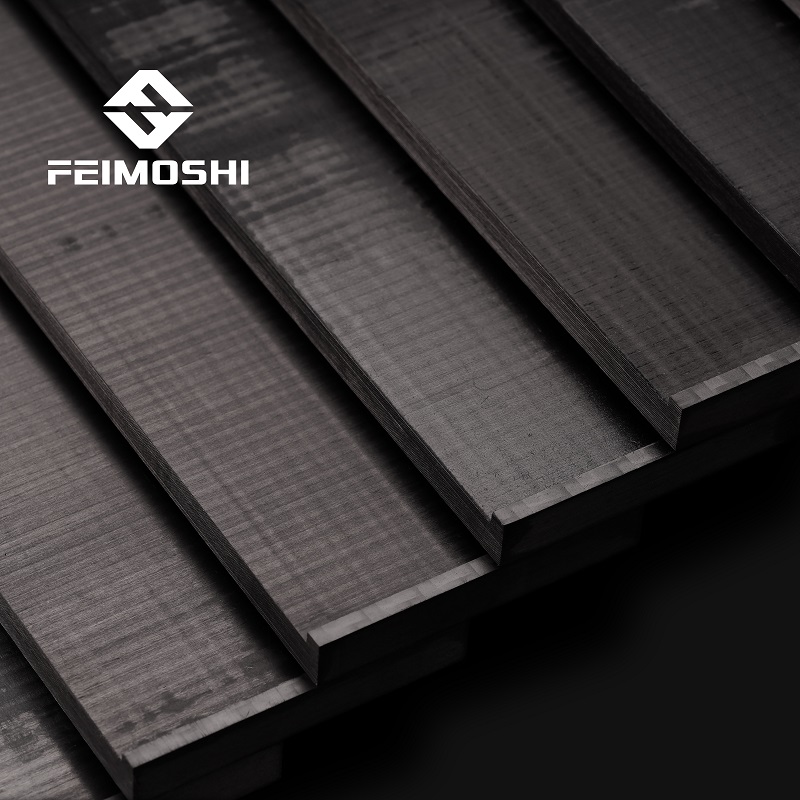

20mm-30mm thick plate is very rigid and strong to take the high weight of goods. It could use in building construction.

Different thickness has the various function for our daily life.

FAQ

1) Do you have the rigid and flexiable carbon fiber board?

Yes, 0.2mm-0.3mm thick is better choice for your using.

2) Do you have MOQ requirement?

No MOQ requirements and sample order is ok for us.

3) How many days for the customized carbon fiber plate?

Normally, 5-7 working days for the plate production.

4) which shipping way do you use?

DHL/Fedex/TNT/EMS/Epacket

5) Paypal is ok?

Yes, Paypal and T/T are both fine.

Looking for ideal UD 3K Twill Carbon Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Laminate Crp Sheets are quality guaranteed. We are China Origin Factory of Drone Frame Cnc Cutting Carbon Fiber. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

After data comparison, it is obvious that there is a gap between the mechanical properties of carbon fiber and carbon fiber composite materials, but even so, the carbon fiber pipe made of carbon fiber composite material far exceeds the pressure bearing capacity of steel pipe. OEM/ODM China Flat Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: United States, Costa Rica, Naples, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.