Online Exporter Carbon Fiber Rc Frame - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi

Online Exporter Carbon Fiber Rc Frame - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi Detail:

Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max

The ultra-thin autoclave kevlar phone case is on sale. Its main features are thinness, toughness, high-quality appearance, and comfortable touch.

Material: autoclave kevlar

Thickness: 0.35mm ultra thin

Finish: autoclave process

MOQ: 10pcs

Color: black, red, blue

Shipping methods: Express services like DHL, UPS, FedEx, TNT, or Air shipping, Sea shipping

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

Note: We support free sample service!

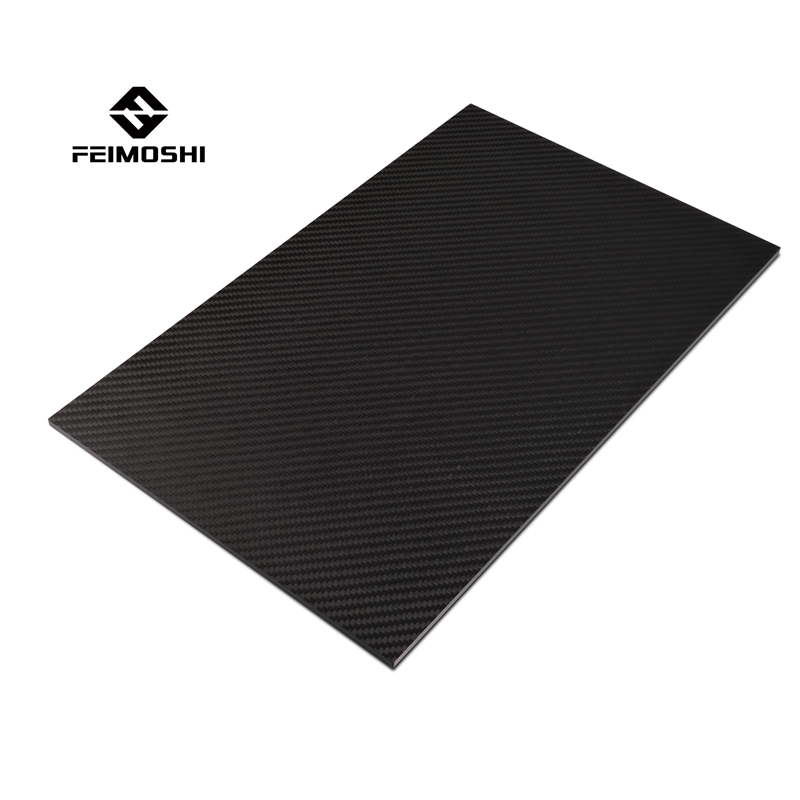

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. Online Exporter Carbon Fiber Rc Frame - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi , The product will supply to all over the world, such as: Holland, Barbados, Guatemala, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!