PriceList for Carbon Fiber Chamfer - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi

PriceList for Carbon Fiber Chamfer - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi Detail:

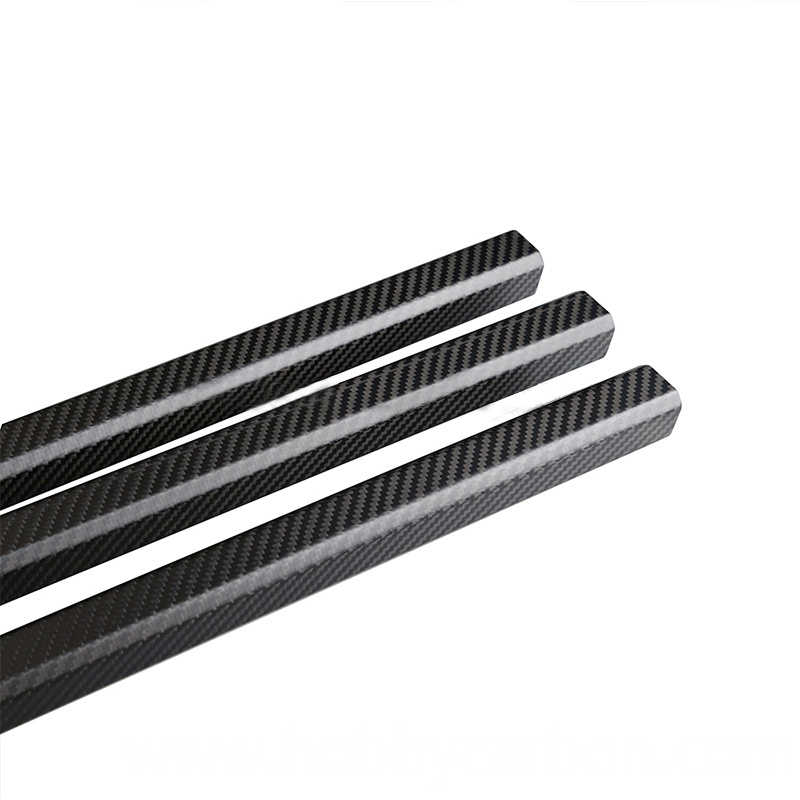

Customized carbon fiber octagonal tube accessories

New upgrading Octagon carbon fiber boom types in stock: 20X30mm, 30X30mm(Length is 1000mm.) We could cut the different length according to your detail requirements( Free cut length charge)

Thicknesss could do the 1.0mm, 1.5mm and 2.0mm or others. Octagon carbon fiber tube is more stable and professional than round carbon fiber tube.

These 3K Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill or plain weave;

Customized specs are accepted, like Outer Diameter : 6mm, 8mm,10mm,12mm,14mm,16mm, 20mm, 22mm, 25mm, 30mm……350mm;

Thickness:

1mm, 1.5mm, 2 mm, 2.5mm, 3mm…..16mm ;any size can do for you .

2.Specifications

1) High temperature resistance carbon fiber tubes:100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

Besides Carbon Fiber Tube, we also can support you with Full Carbon Fiber Sheet, shaped carbon fiber parts, carbon fiber prototyping, carbon fiber guitar, carbon fiber rc chassis and carbon fiber furniture and so on.

We have about ten years more experience in carbon fiber market. Assembly serivce and packing service is welcomed by most customers. Any other requirements, please don’t hesitate to contact us.

Welcome to quote

Specification in common use

|

23mm*25mm*1000mm |

20mm*22mm*1000mm |

|

19.5mm*22mm*1000mm |

18mm*20mm*1000mm |

|

18mm*16mm*1000mm |

14mm*16mm*1000mm |

|

10mm*12mm*1000mm |

8mm*10mm*1000mm |

|

6mm*8mm*1000mm |

can custom as per customer’s requires |

FAQ

1) Do we need to make a mould for the shaped carbon fiber tube?

Yes, most of carbon fiber tube needs a mould to do it. And it will make the tube more straight and strength.

2) There is the moq requirements of shaped carbon fiber tube?

If you make the new mould for your project, the testing order is no moq for you.

3)When we decide to make the mould, it needs to make the payment for each order?

No, mould charge only need to pay one time. Ant the mould is only for you.

4) Could we sign the NDA?

Yes, it is ok for us. And it is also our duty to protect every customer’s design.

Looking for ideal Carbon Fiber Arms Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the X Class Frame are quality guaranteed. We are China Origin Factory of Big Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber board is a composite material composed of carbon fiber filaments and resin. The resulting product is lightweight, yet strong and durable. Carbon fiber sheets come in many different types to suit a variety of applications and industries, including automotive and aerospace. PriceList for Carbon Fiber Chamfer - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi , The product will supply to all over the world, such as: Jersey, Ecuador, Armenia, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.