Professional China Composite Pipe - 3K Twill Matte Full Carbon Fiber Tubes – Feimoshi

Professional China Composite Pipe - 3K Twill Matte Full Carbon Fiber Tubes – Feimoshi Detail:

3K Twill Matte Full Carbon Fiber Tubes

Product Description

Carbon Fiber Tube is composed of Carbon Fiber Twill (or Plain) Weave Fabric, Unidirectional Carbon Fiber prepreg and epoxy resin. The tube is firstly table rolled with a mandrel of certain diameter and length.Then put into the oven of high temperature for thermoset process. To reach high precision, the tubes are usually ground and then put onto the epoxy spray if Glossy shinny finish needed.

Pipes of various materials: Full Carbon Fiber Tube,Glass Fiber Tube, Carbon Glass Tube.

Carbon fiber tube could be widly used copter, gimbal, FPV frame, Medical, handguard. More and more people know the carbon fiber material feature a lot. It is also applied to our daily life, such as carbon fiber furniture, carbon fiber guitar, carbon fiber wallet, carbon fiber ruler. carbon fiber chassis, carbon fiber use in constructions and so on. We believe that carbon fiber will be more popular in the market.

Any customized carbon fiber parts, please don’t hesitate to contact us.

FAQ

1, Do you do the customized tube?

Yes, we could do it according to your drawings.

2, There is MOQ requirements?

Normally, for the stock one, there is no MOQ requirements.

3, Sample is ok for you?

Yes, Free samples is available, Only need to pay the shipping cost.

4, Which types do you have for the stocked?

We have Octagon carbon fiber tube, Round carbon fiber tube, Curved carbon fiber boom in stock.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

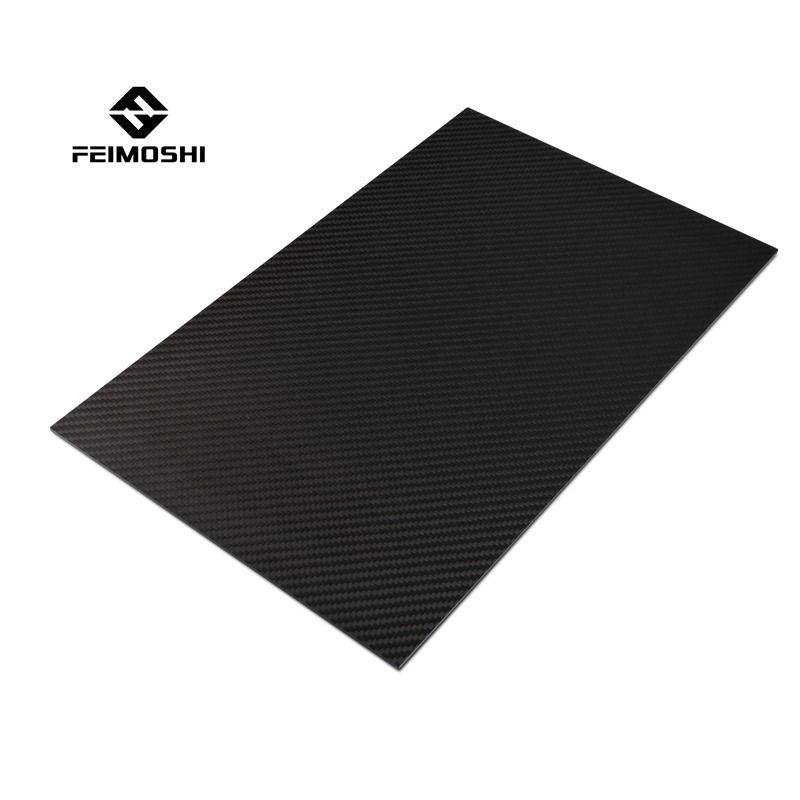

Product detail pictures:

Related Product Guide:

Carbon fiber tube is one of the more common application forms of carbon fiber composite materials in industrial, civil, medical and other fields. Due to its advantages of light weight, high strength and flexible design, it has the development trend of becoming a new generation of parts and components. Professional China Composite Pipe - 3K Twill Matte Full Carbon Fiber Tubes – Feimoshi , The product will supply to all over the world, such as: Peru, Juventus, Tunisia, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!