Reasonable price Carbon Plastic Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi

Reasonable price Carbon Plastic Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi Detail:

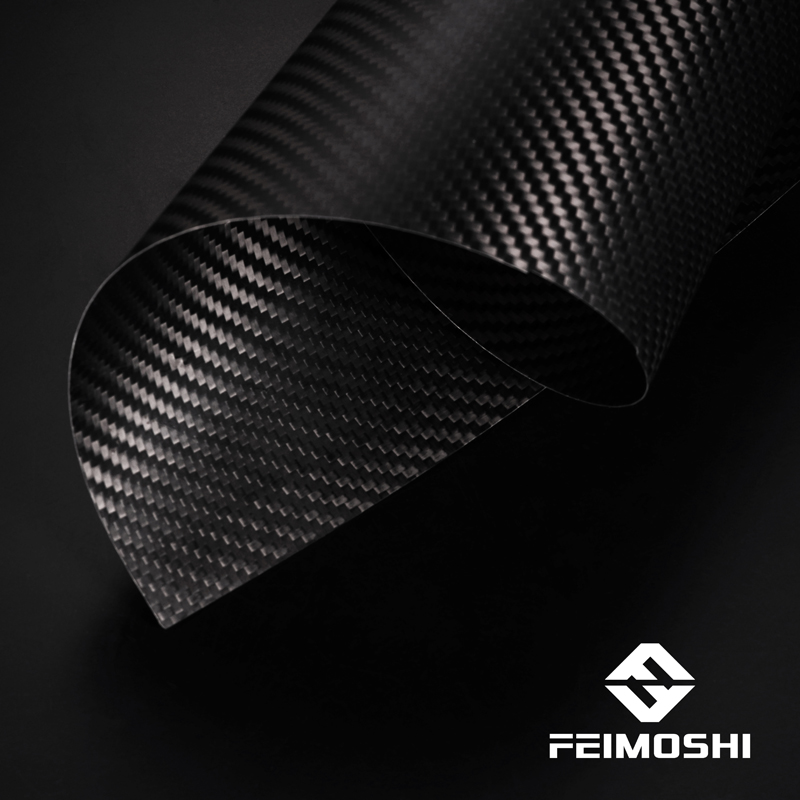

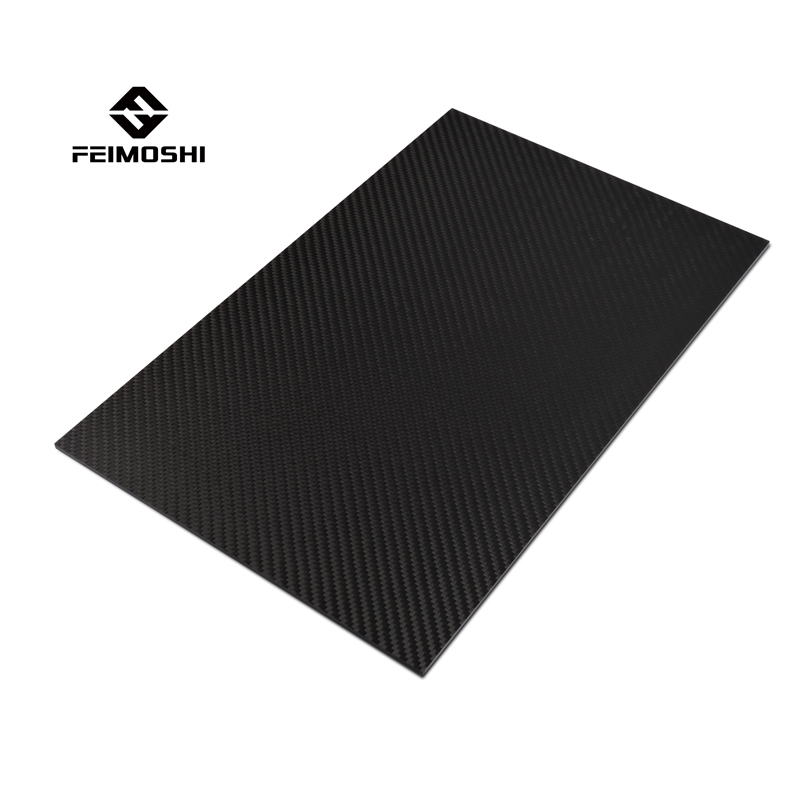

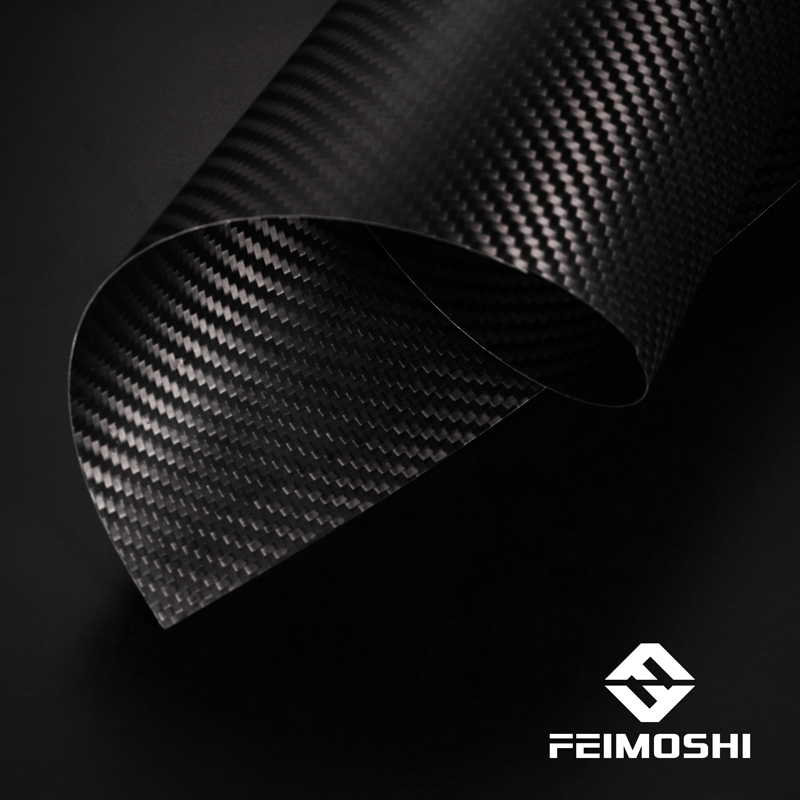

0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet

Carbon fiber is a new kind of high strength and high modulus fiber material with more than 95% carbon content.

Carbon fibers are flexible and rigid with outstanding mechanical performance.

The tensile strength of carbon fibers is several times that of steel.

Carbon fiber has 0.2mm-30mm thickness and 0.2-0.5mm thick plate is rigid and flexiable. And it could make the customers more creative.

You could inform me your ideal and we will help you to make it come true.

20mm-30mm thick plate is very rigid and strong to take the high weight of goods. It could use in building construction.

Different thickness has the various function for our daily life.

FAQ

1) Do you have the rigid and flexiable carbon fiber board?

Yes, 0.2mm-0.3mm thick is better choice for your using.

2) Do you have MOQ requirement?

No MOQ requirements and sample order is ok for us.

3) How many days for the customized carbon fiber plate?

Normally, 5-7 working days for the plate production.

4) which shipping way do you use?

DHL/Fedex/TNT/EMS/Epacket

5) Paypal is ok?

Yes, Paypal and T/T are both fine.

Looking for ideal UD 3K Twill Carbon Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Laminate Crp Sheets are quality guaranteed. We are China Origin Factory of Drone Frame Cnc Cutting Carbon Fiber. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. Reasonable price Carbon Plastic Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Vietnam, India, Las Vegas, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.