Short Lead Time for Carbon Fiber Longboard - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi

Short Lead Time for Carbon Fiber Longboard - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi Detail:

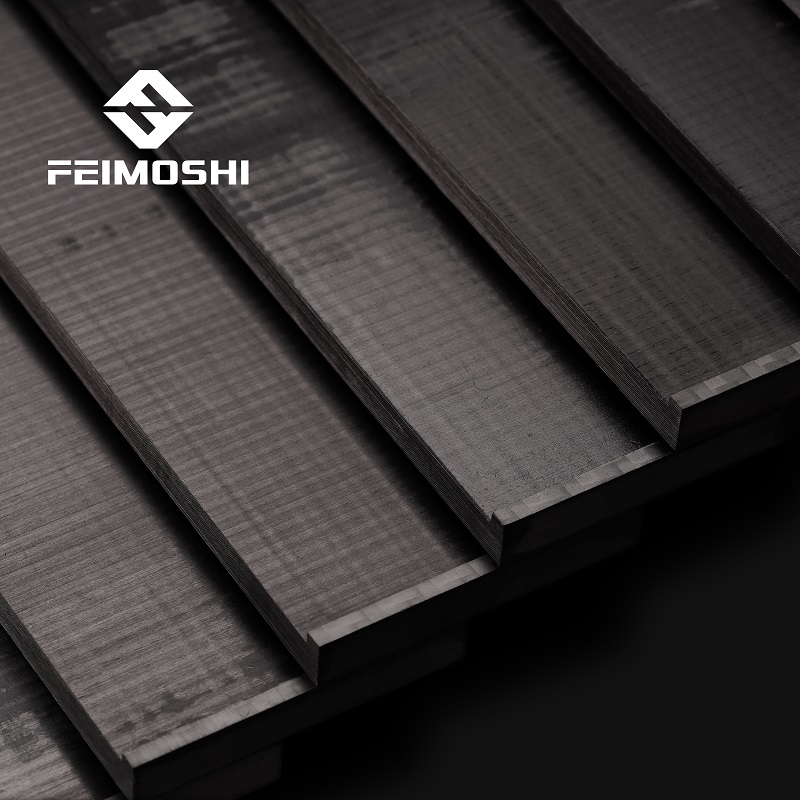

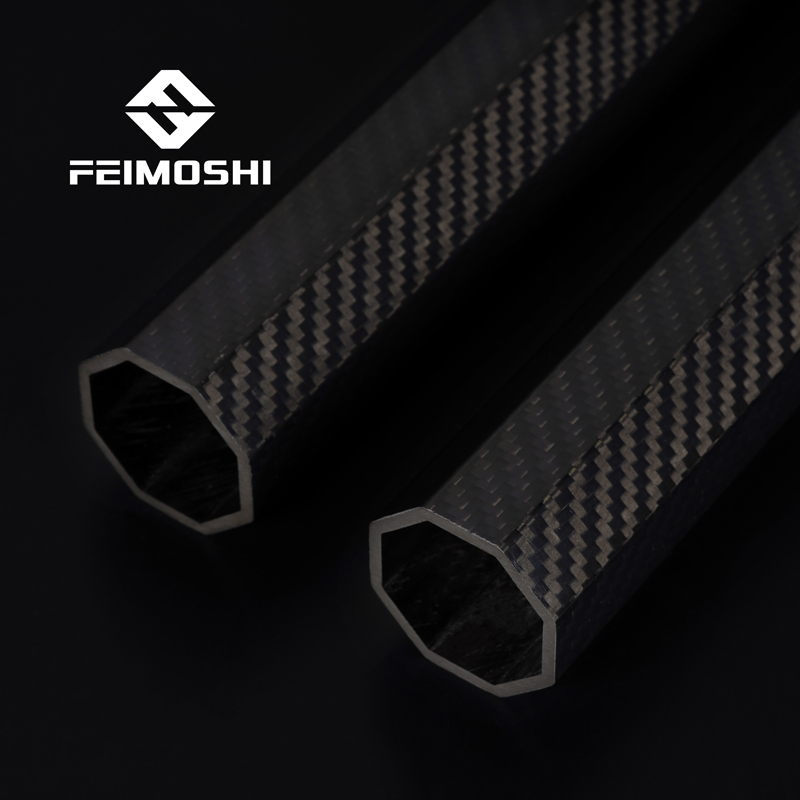

DIY 3K large diameter Carbon fiber round/square rod boom

Product Description

Our Carbon Fiber Tube is great performance and appearance. Made from attractive pattern plain twill or as customer requirement.

We make the Carbon Fiber Tubes by rolling-Wrapped process. It makes the carbon fiber tube much stronger and professional. More and more customers choose the full carbon fiber tube to make the drone arm, desk leg, gimbal stand and so on. And you could offer your creative ideal, we could help you to come ture. Carbon fiber tube is also widly used in building construction. It makes them much lighter and easy to move.

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Looking for ideal Carbon Fiber carbon fiber tube Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Epoxy Resin Carbon Fiber 3k Woven are quality guaranteed. We are China Origin Factory of Carbon Fiber Shape. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber was produced in the early 1950s in response to the needs of cutting-edge science and technology such as rockets, aerospace and aviation, and is now widely used in sports equipment, textiles, chemical machinery and medicine. With the increasingly stringent requirements of cutting-edge technology on the technical performance of new materials, scientific and technological workers are constantly striving to improve. In the early 1980s, high-performance and ultra-high-performance carbon fibers appeared one after another, which was another leap in technology, and also marked that the research and production of carbon fibers had entered an advanced stage. Short Lead Time for Carbon Fiber Longboard - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi , The product will supply to all over the world, such as: Nairobi, Haiti, Brisbane, At the time of winding, the carbon fiber should be stable and not deviated, and the surface of the mandrel should be uniformly and continuously covered. Arranged according to a certain law, so that adjacent chemical fibers are neither easy to overlap nor have gaps, this law is called "winding law". The winding laws are different, and the quality of the carbon fiber pipes is also different. The proper design of the winding shape can ensure the quality of the carbon fiber pipes.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.