Trending Products Carbon Fiber Keyboard Case - 3K 100% Carbon Fiber Curved Carbon Fiber Tube – Feimoshi

Trending Products Carbon Fiber Keyboard Case - 3K 100% Carbon Fiber Curved Carbon Fiber Tube – Feimoshi Detail:

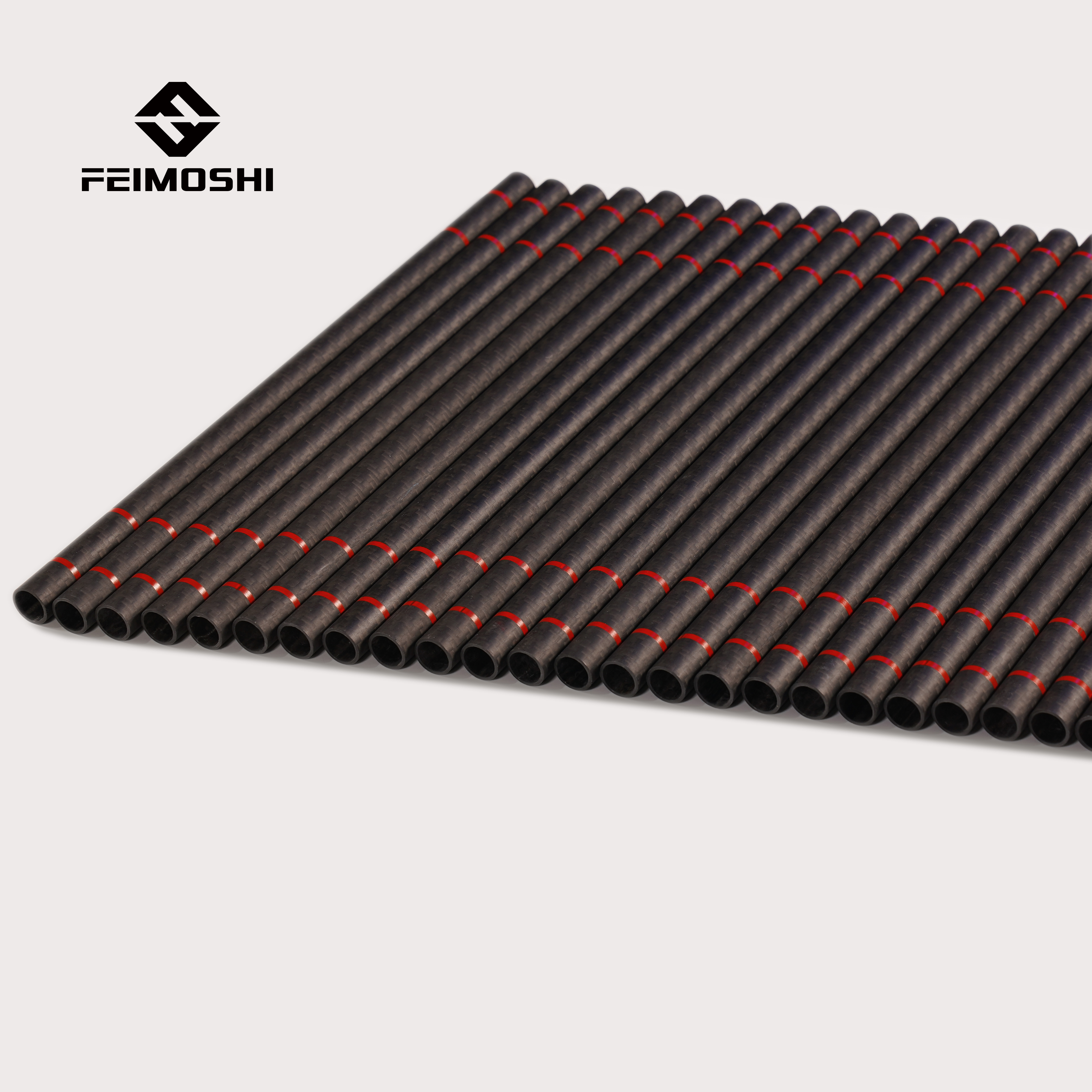

3K 100% customized shaped Carbon Fiber Curved Tube

Recently we have 25mm curved carbon fiber tube and 22mm curved carbon fiber tube. The two size curved carbon fiber tube is used on gimbal and bike handle. It is lighter than the stainless steel or steel handle. Most people choose these two handle for upgrading their frames. It makes the frame more professional. For the two size handle, there is no need mould charge to save the cost for your using.

Customized shaped carbon fiber tube is avaliable tube. We have various size carbon fiber round tube, carbon fiber octagon tube, carbon fiber square tube in stock. Also we could custom the different and unique size carbon fiber tube for your using. Any interests, please contact us.

Customization Process

1.Please contact freely and provide us with your drawings and specifications ;

2.We will quote for you within 1-3 days;

3.Orders need to pay the total purchase price of more than 30 percent down payment;

4.Confirm the sample;

5.Batch manufacturing;

6.Inform the customer to inspection the package;

7.Customers pay the balance payment;

8.Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal 3K 100% Carbon Curved Tubes Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Curved Carbon Fiber Tube are quality guaranteed. We are China Origin Factory of Full Carbon Bent Tubes. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Trending Products Carbon Fiber Keyboard Case - 3K 100% Carbon Fiber Curved Carbon Fiber Tube – Feimoshi , The product will supply to all over the world, such as: Macedonia, Spain, South Africa, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!