Trending Products Carbon Fiber Keyboard Case - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi

Trending Products Carbon Fiber Keyboard Case - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi Detail:

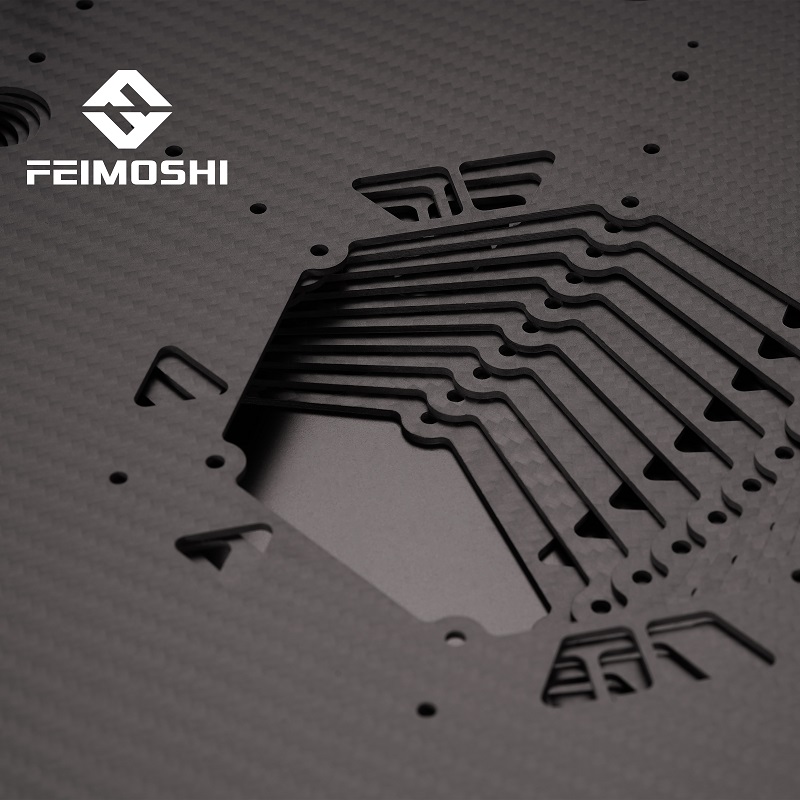

3K Carbon fiber Octagon tube square boom for handguard

Carbon Fiber Tube has light,high strength, wearable, and a very low CTE (coefficient of thermal expansion), moreover ,carbon fiber does not transfer heat as much as most metals.

One of the biggest benefits of using composite tubing in general is the ability of the material to resist weather much better than metals,because it will not corroded .

Our product widely uses in aviation, space flight, automobile, toy, kite, pens, handicraft, tent, windmill, umbrella, each kind of sports equipment and so on

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness: 0.5mm/1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Techniques: Rolling-wrapping

Advantage: High-Strength, light weight, Corrosion Resistant etc.

Service: Logo Service, CNC Cutting carbon fiber Service, Packing and assembly service

Many octagon full carbon tubes in stock, mixed order is welcome.

If any interesting in pls feel to contact us. We will do our best to support you.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal Carbon Fiber Square Tube for Sale Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Square Poles are quality guaranteed. We are China Origin Factory of Carbon Fiber Square Tube 6mm. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

In the automotive industry, carbon fiber sheets are used to strengthen automotive components such as doors, hoods, bumpers, fenders and roof rails. Automakers often use steel to make these parts. Although less expensive, steel is much heavier than carbon fiber. To make vehicles such as race cars lighter, carbon fiber sheets are often used to replace many steel parts. Trending Products Carbon Fiber Keyboard Case - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi , The product will supply to all over the world, such as: New York, Hyderabad, Uruguay, The surface of the wound carbon fiber prepreg must be coated with a layer of OPP, and then the wound carbon fiber tube is sent to a high-temperature curing furnace to dry and form, and finally the mold is released, and the unstable parts on both sides are cut off to carry out production and processing solutions.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!