Wholesale Price China Diy Carbon Fiber Tube - curved 3k full carbon fiber tubes – Feimoshi

Wholesale Price China Diy Carbon Fiber Tube - curved 3k full carbon fiber tubes – Feimoshi Detail:

Introduction

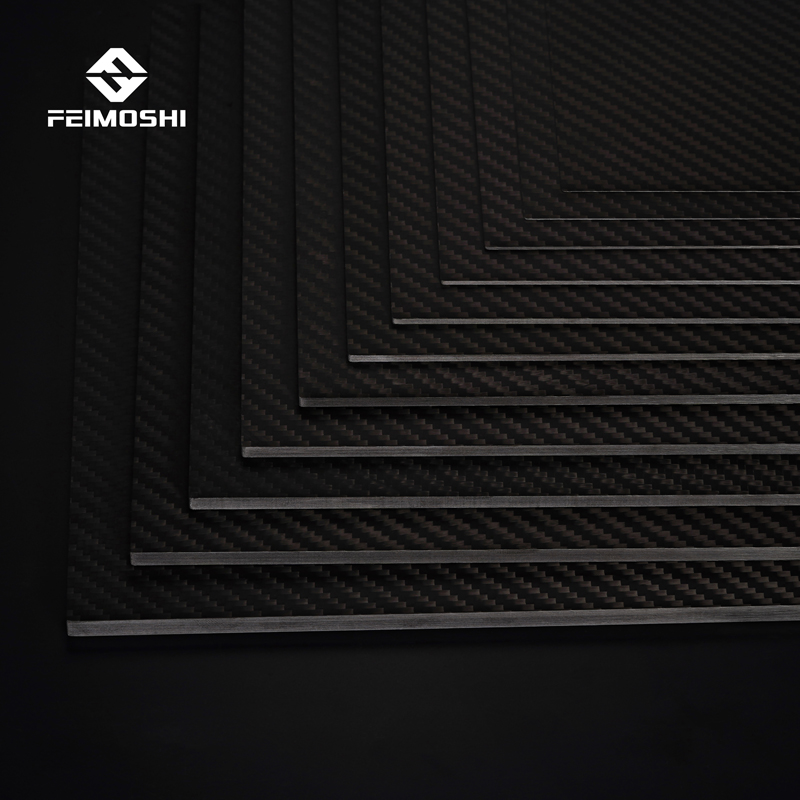

The 3K Carbon Fiber Tubes are made of pure carbon fiber with beautiful twill or plain weave; Available in different colors and sizes( usually Black color);

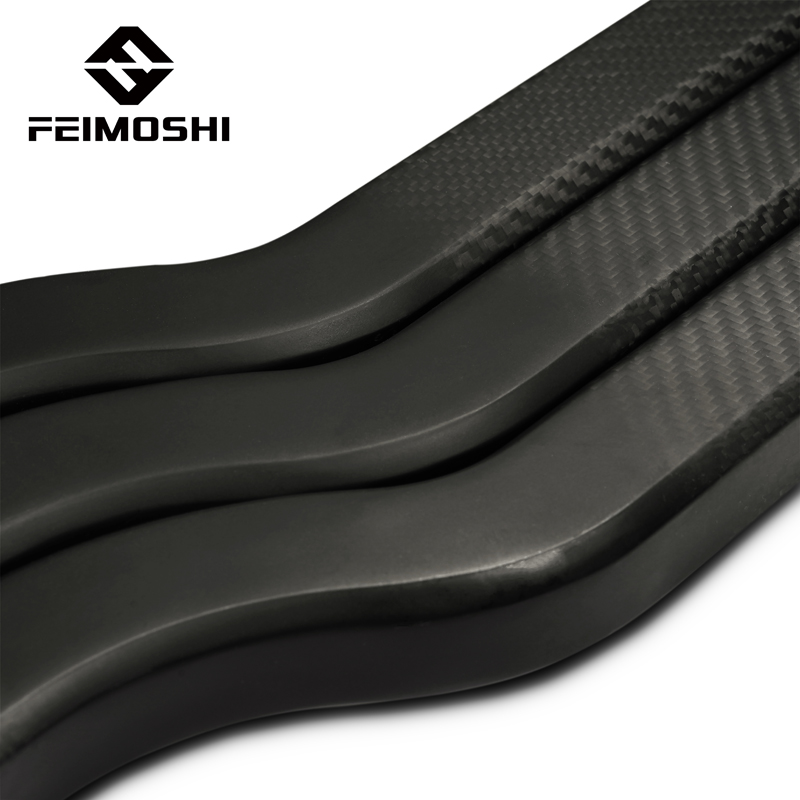

All kind of tubes can be curved after processing.

Surface Finish: Glossy and Matte

Specifications

1) High temperature resistance;

2) Light & high strength;

3) Good corrosion resistance;

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. Wholesale Price China Diy Carbon Fiber Tube - curved 3k full carbon fiber tubes – Feimoshi , The product will supply to all over the world, such as: Libya, Norwegian, Adelaide, The surface of the wound carbon fiber prepreg must be coated with a layer of OPP, and then the wound carbon fiber tube is sent to a high-temperature curing furnace to dry and form, and finally the mold is released, and the unstable parts on both sides are cut off to carry out production and processing solutions.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Send your message to us:

Write your message here and send it to us