Wholesale Rc Composite Frame - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi

Wholesale Rc Composite Frame - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi Detail:

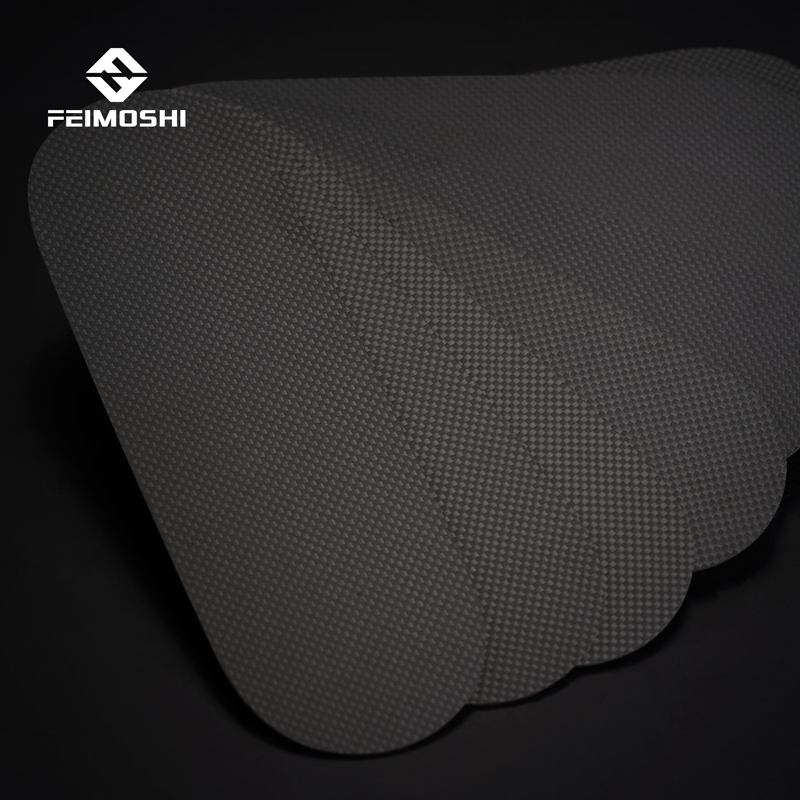

2.0mm Twill matte CNC carbon fiber composite cutting opener mount

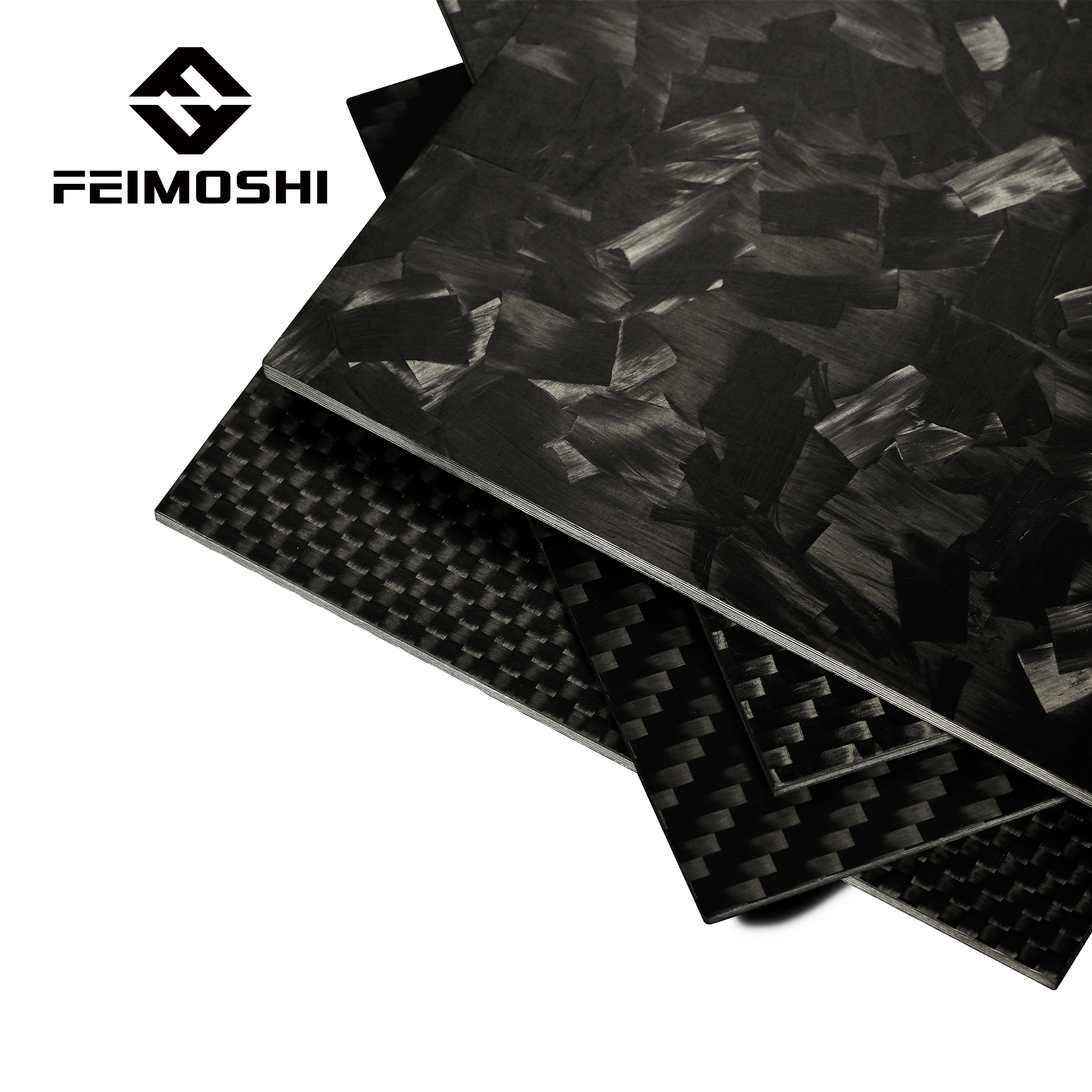

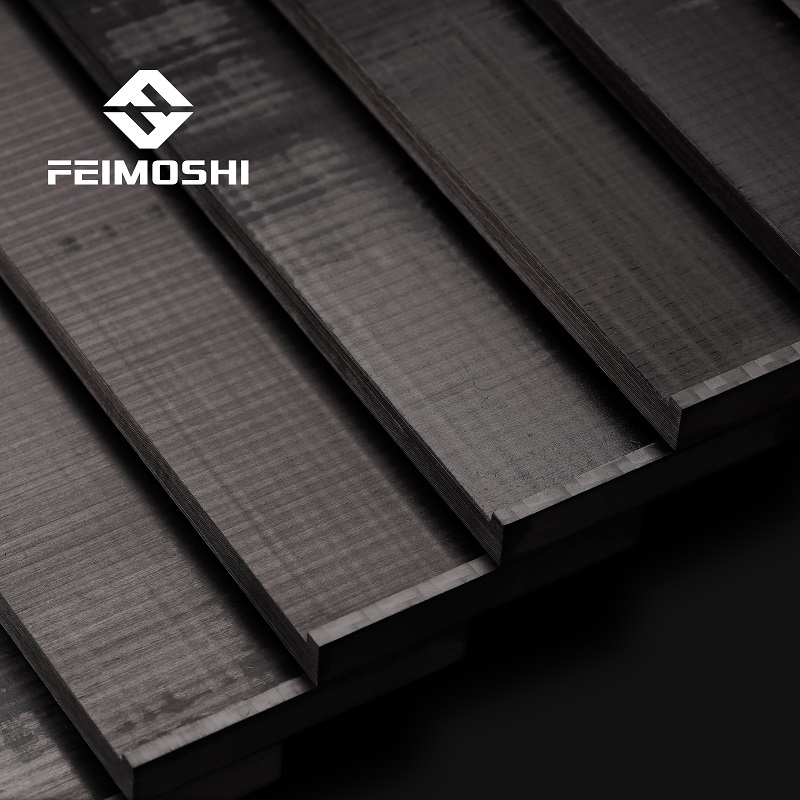

400X500X2.0mm and 500X600X2.0mm 3K twill matte carbon fiber plate could be cut to different types. 2.0mm thickness is very suitable for the carbon fiber opener. Normally, we could do some stocked quantity for 2.0mm thickness. Carbon fiber sheet is made of 3K twill matte cloth and UD cloth and epoxy resin.

CNC cutting service is ok for us. If you feel that the edge is very sharp, we could do the chamfer for the edge to make it more professional. Also wanting to connect the hardware with carbon fiber parts, contact us freely. Our engineer team will offer some good suggestions for your choosing.

Product detail pictures:

Related Product Guide:

After data comparison, it is obvious that there is a gap between the mechanical properties of carbon fiber and carbon fiber composite materials, but even so, the carbon fiber pipe made of carbon fiber composite material far exceeds the pressure bearing capacity of steel pipe. Wholesale Rc Composite Frame - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi , The product will supply to all over the world, such as: Boston, Muscat, Munich, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

Send your message to us:

Write your message here and send it to us