100% Original Fpv Racing Drone – CNC machining carbon fiber parts cutting for drone – Feimoshi

100% Original Fpv Racing Drone – CNC machining carbon fiber parts cutting for drone – Feimoshi Detail:

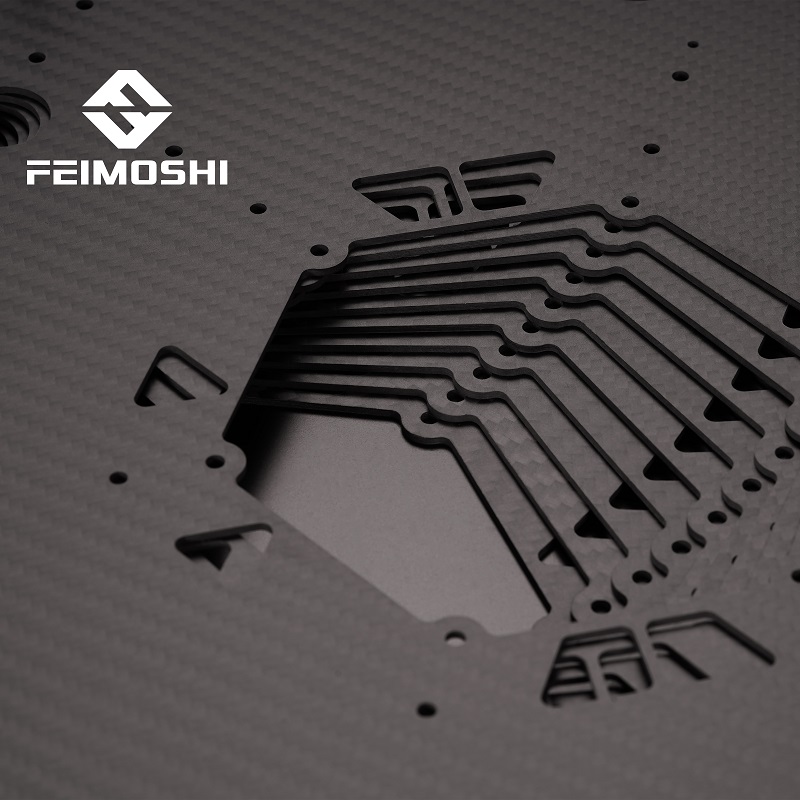

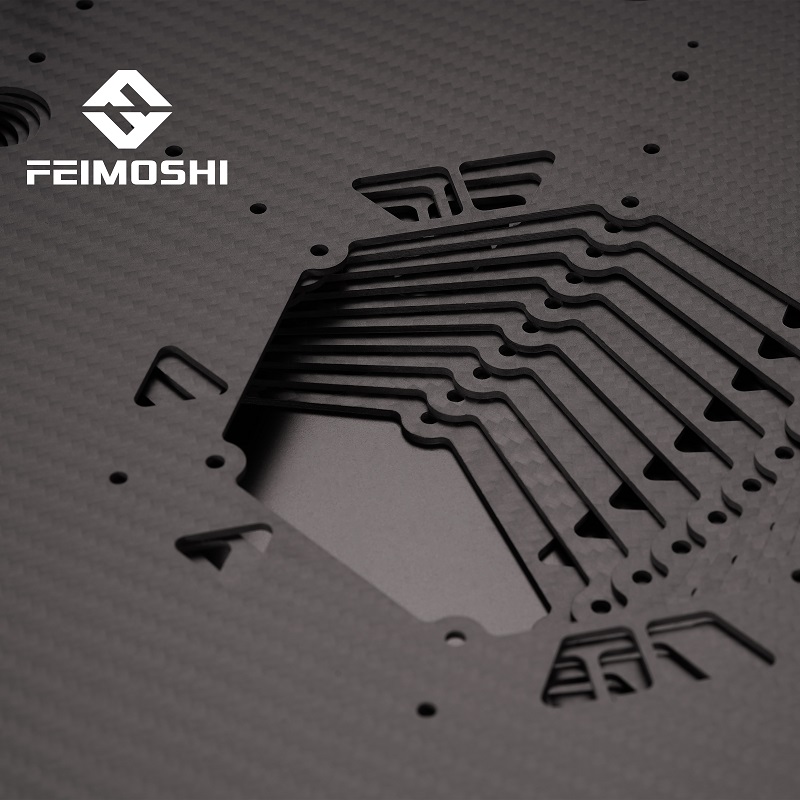

CNC machining carbon fiber parts cutting for drone

FEIMOSHI is a proffessional manufacturer of carbon fiber products, loved by drone customers and our CNC cutting process has won their praise. CNC machining is precision and cost-effective way to achieve innovation and creativity, which triggers out our endless imagination and creative inspiration. We had made so many different carbon fiber CNC parts for racing parts, RC helicopters, bicycle bracket, and reinforcements for 10 years.

Feature:

Surface: Matter/Light/Twill/plain

Size: OEM(STEP, DWG or other)

Material: 100% carbon fiber

Shape: Smooth

Technical: FPV/Drone/UAV/RC Frame

Applications:

1. Aerospace, Helicopters Model Drone ,UAVS, FPV

2. RC model parts

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. building construction repair and strengthening

Our service

Any needs, please feel free to contact me!

Express: Fedex, UPS, DHL, TNT

Delivery time: about 5-10 working days

After-sales service

Product detail pictures:

Related Product Guide:

Carbon fiber greatly improves the characteristics of special-shaped parts. At this stage, carbon fiber special-shaped products have many requirements in the fields of unmanned aircraft, auto parts, intelligent robots, etc. 100% Original Fpv Racing Drone – CNC machining carbon fiber parts cutting for drone – Feimoshi , The product will supply to all over the world, such as: Colombia, Doha, Swiss, With the improvement of the production process, carbon fiber board will popularize or replace many metal structural materials, providing the possibility for the lightness and convenience of products.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.