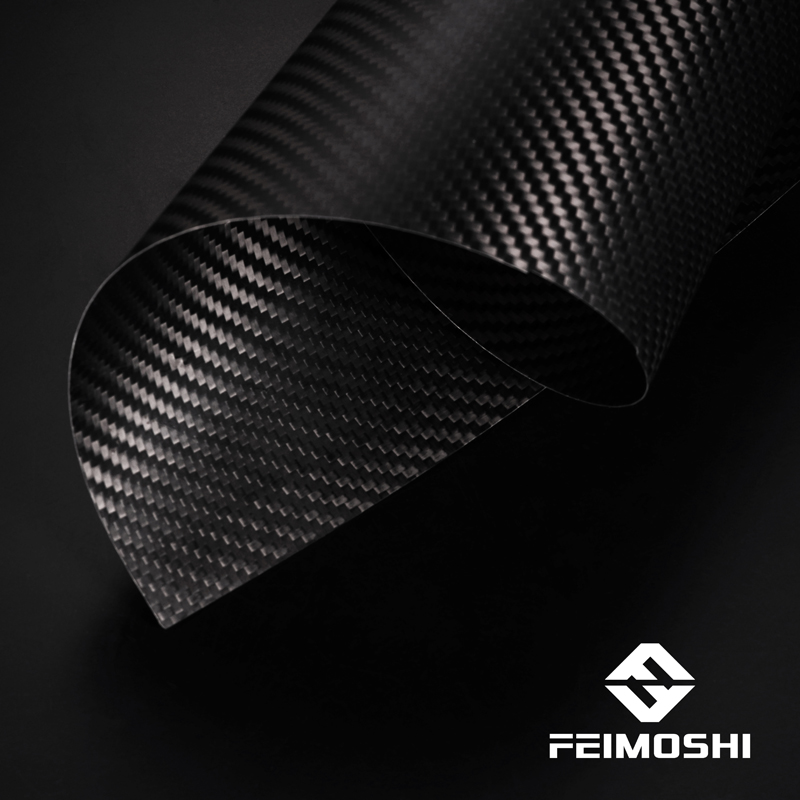

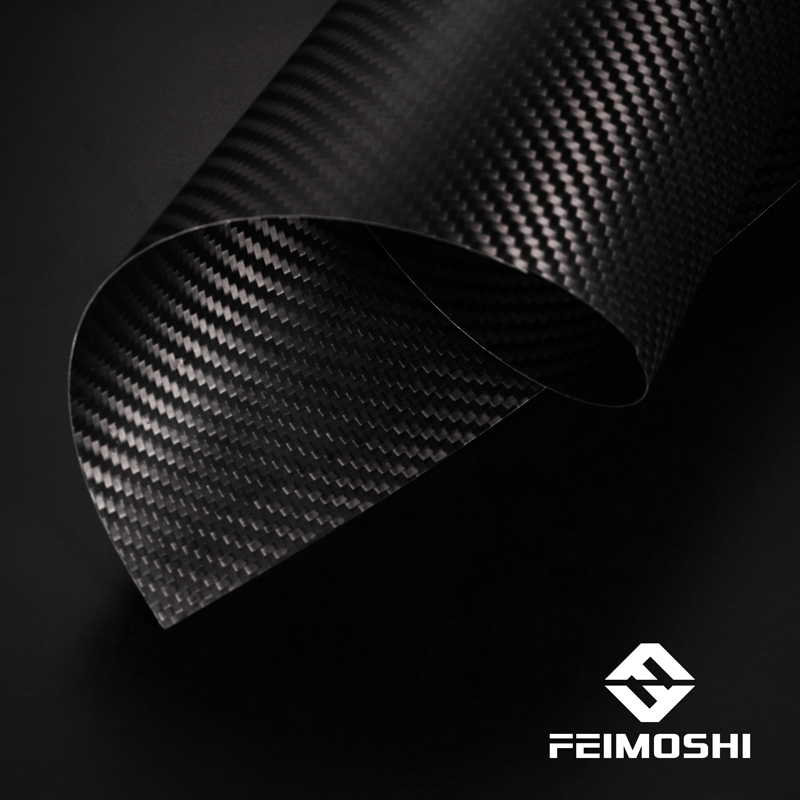

2021 China New Design 3k Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi

2021 China New Design 3k Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi Detail:

0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet

Carbon fiber is a new kind of high strength and high modulus fiber material with more than 95% carbon content.

Carbon fibers are flexible and rigid with outstanding mechanical performance.

The tensile strength of carbon fibers is several times that of steel.

Carbon fiber has 0.2mm-30mm thickness and 0.2-0.5mm thick plate is rigid and flexiable. And it could make the customers more creative.

You could inform me your ideal and we will help you to make it come true.

20mm-30mm thick plate is very rigid and strong to take the high weight of goods. It could use in building construction.

Different thickness has the various function for our daily life.

FAQ

1) Do you have the rigid and flexiable carbon fiber board?

Yes, 0.2mm-0.3mm thick is better choice for your using.

2) Do you have MOQ requirement?

No MOQ requirements and sample order is ok for us.

3) How many days for the customized carbon fiber plate?

Normally, 5-7 working days for the plate production.

4) which shipping way do you use?

DHL/Fedex/TNT/EMS/Epacket

5) Paypal is ok?

Yes, Paypal and T/T are both fine.

Looking for ideal UD 3K Twill Carbon Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Laminate Crp Sheets are quality guaranteed. We are China Origin Factory of Drone Frame Cnc Cutting Carbon Fiber. If you have any question, please feel free to contact us.

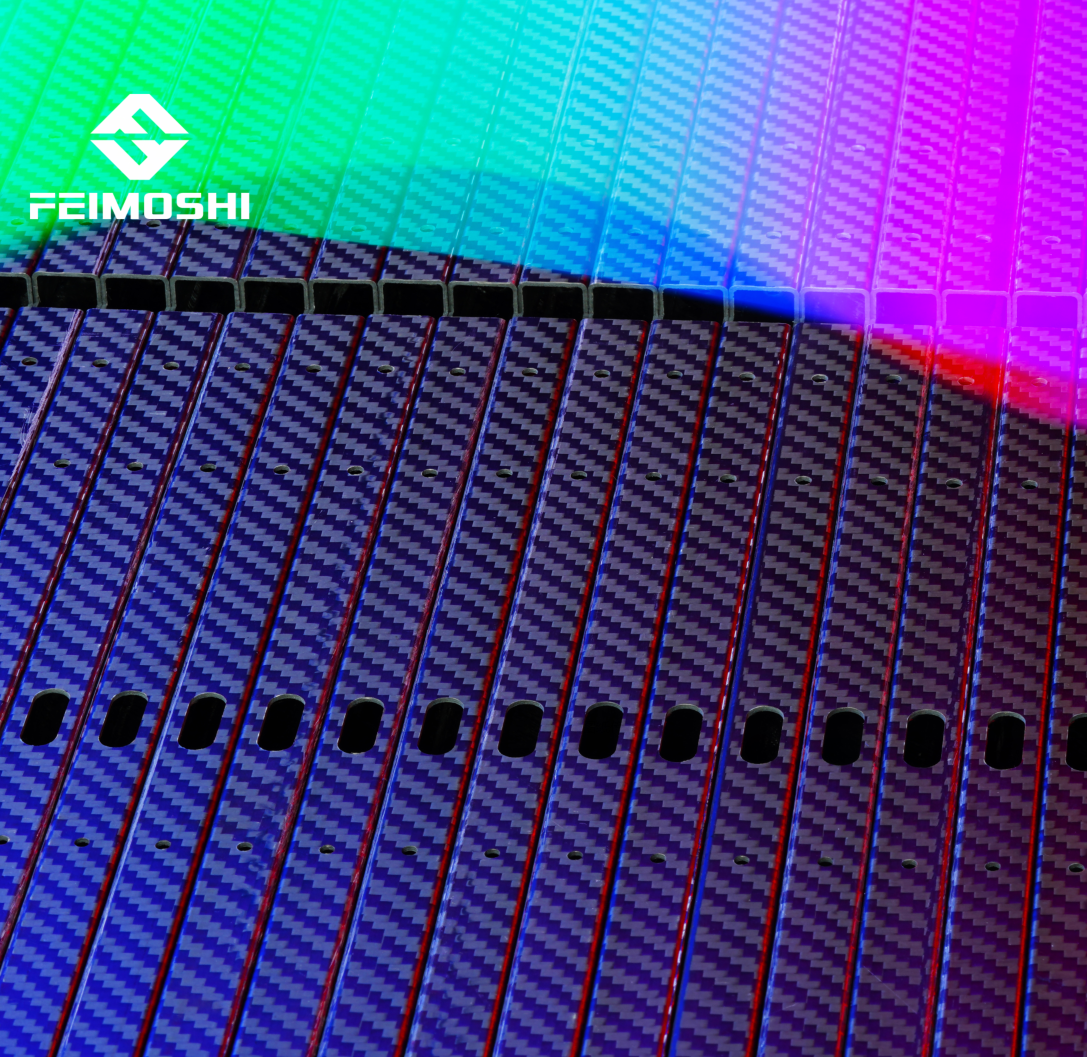

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. 2021 China New Design 3k Carbon Fiber Sheet - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Nepal, Austria, Surabaya, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.