2021 China New Design Carbon Fiber Chassis - 100% shaped Carbon fiber square Octagon tube – Feimoshi

2021 China New Design Carbon Fiber Chassis - 100% shaped Carbon fiber square Octagon tube – Feimoshi Detail:

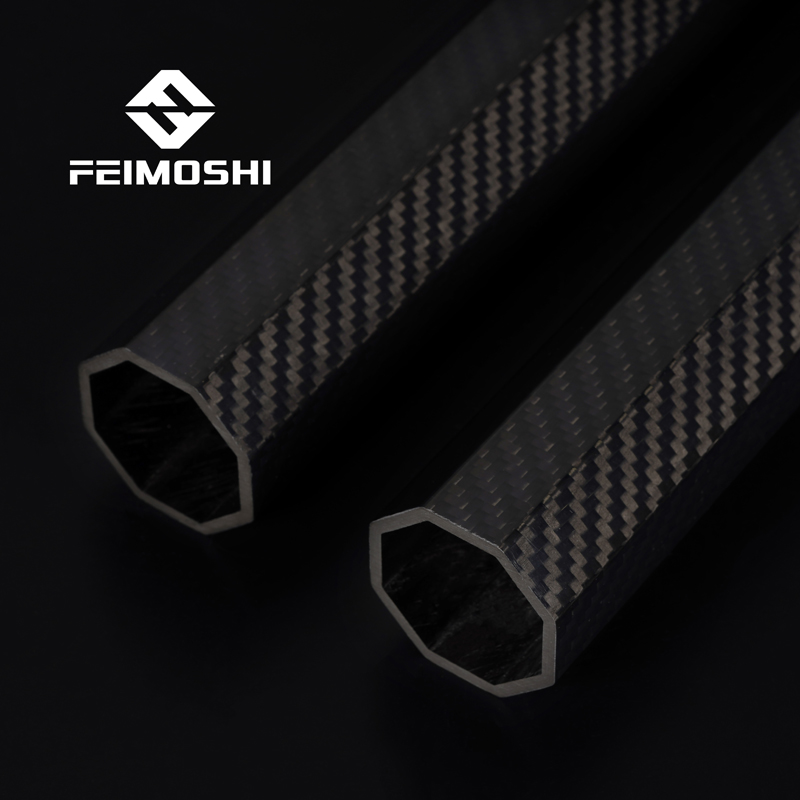

100% shaped Carbon fiber square Octagon tube

Product Description

Carbon Fiber Tube has light,high strength, wearable, and a very low CTE (coefficient of thermal expansion), moreover ,carbon fiber does not transfer heat as much as most metals.

One of the biggest benefits of using composite tubing in general is the ability of the material to resist weather much better than metals,because it will not corroded .

Our product widely uses in aviation, space flight, automobile, toy, kite, pens, handicraft, tent, windmill, umbrella, each kind of sports equipment and so on

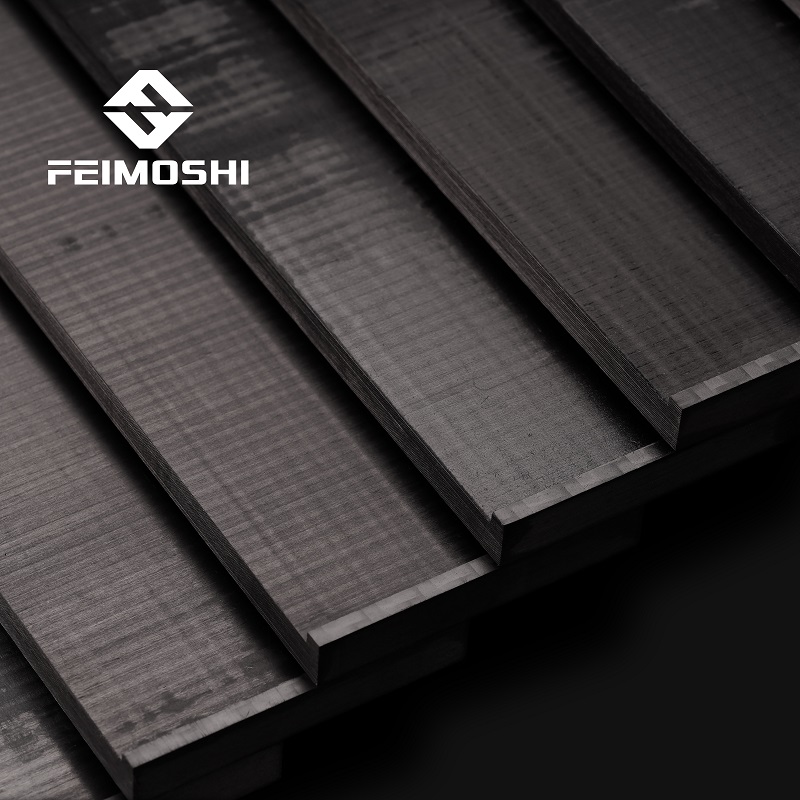

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length:longest length is 1500mm

Appearance: 3K twill weave, plain weave, or other

Type: round carbon fiber tube, Octagon carbon fiber boom, rectangle carbon fiber tube, curved carbon fiber pipe, carbon fiber square tube or customized carbon fiber

Service: Logo Service

Many octagon full carbon tubes in stock, mixed order is welcome.

If any interesting in pls feel to contact us. We will do our best to support you.

FAQ

1. Sample&Small Order?

Welcome to sample order to test and checking quality. Mixed samples are acceptable.

2. Lead Time

According to order volume answer production time. Never cheat customers!

3. MOQ

Accpet small order&Servicer will depending on details situation provide some advices.

4. Goods Shipping

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

5. Visit Company

No problem for us, also we will provide technical support!

Looking for ideal Carbon Fiber Square Rod Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Square Tubing are quality guaranteed. We are China Origin Factory of Carbon Fiber Square Stock. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. 2021 China New Design Carbon Fiber Chassis - 100% shaped Carbon fiber square Octagon tube – Feimoshi , The product will supply to all over the world, such as: Finland, Greek, Netherlands, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly