Best quality Forged Carbon Fiber Sheet - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi

Best quality Forged Carbon Fiber Sheet - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi Detail:

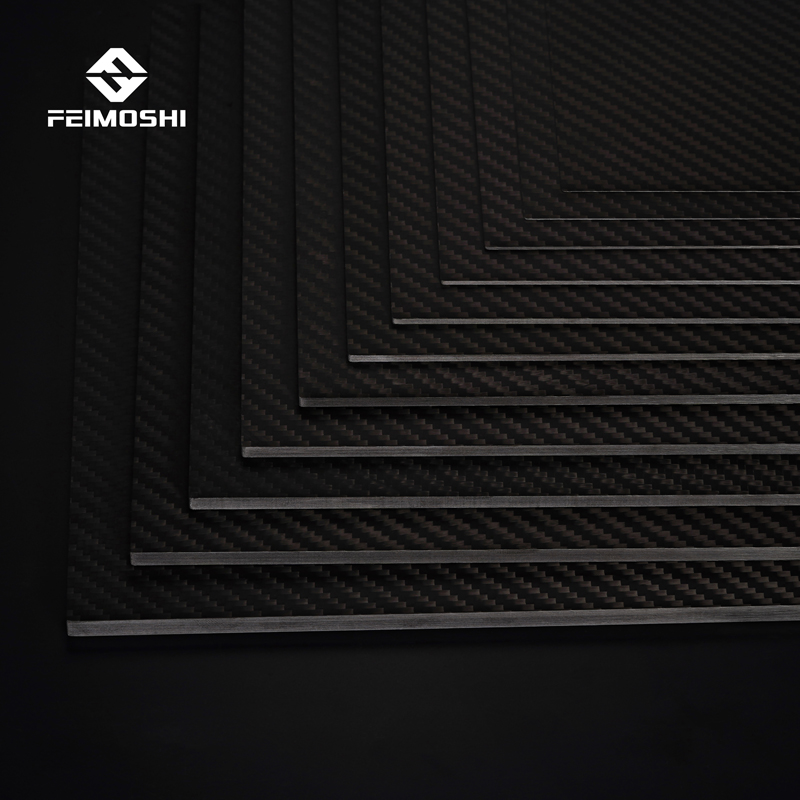

1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet

1K means 1 carbon yarn contains 1000 filaments, 2K means 2000 filaments, and so on. We have 1K/3K/6K/12K carbon fiber fabric. The smaller K is, more complicated the production process is! so the small K carbon fiber fabric is more expensive.

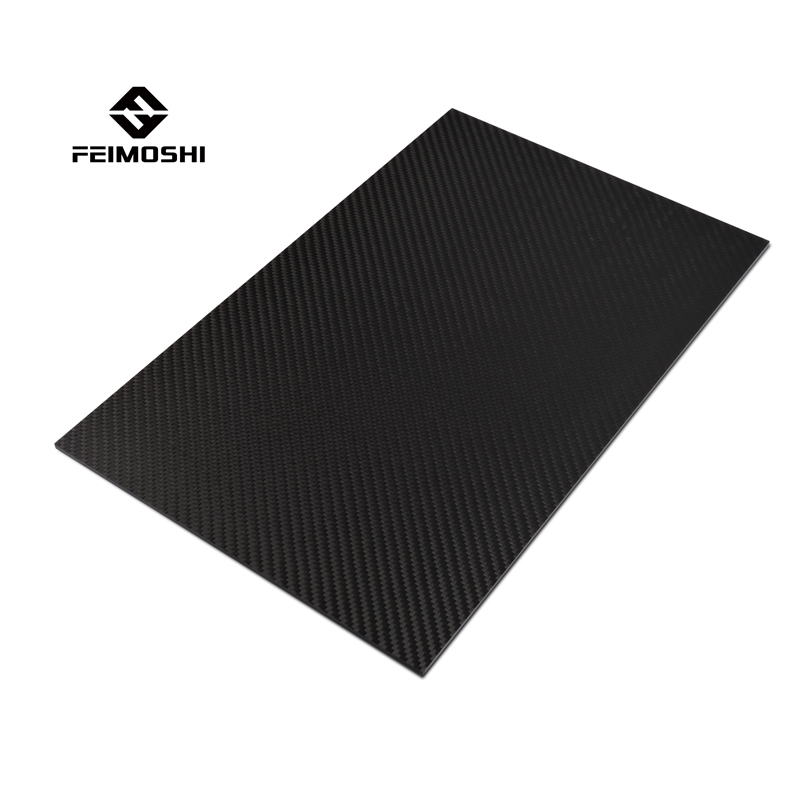

Carbon Fiber Cloth is made of carbon fiber by woven unidirectional, plain weaving or twill weaving style. The carbon fibers we use contain high strength-to-weight and stiffness-to-weight ratios, carbon fabrics are thermally and electrically conductive and exhibit excellent fatigue resistance. When properly engineered, carbon fabric composites can achieve the strength and stiffness of metals at significant weight savings. Carbon fabrics are compatible with various resin systems including epoxy, polyester and vinyl ester resins.

There are unidirectional carbon fiber fabric used as reinforcement clothing for bridge, road and building. The bidirectional cabon fiber fabric are woven with Plain ,Twill style,satin weave and other pattern.

we have 100gsm/120gsm/140gsm/200gsm/240gsm/280gsm/320gsm/400gsm/480gsm/640gsm for choosing.

Looking for ideal 3k Carbon Fiber Sheet 2.5mm Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Zoltek Carbon Fiber Data Sheet are quality guaranteed. We are China Origin Factory of Carbon Fiber Topsheet Snowboard. If you have any question, please feel free to contact us.

Product Categories : Carbon Fiber Sheet > Full Carbon Fiber Sheet

Product detail pictures:

Related Product Guide:

1. The net weight of carbon fiber products is relatively light. The extraordinary light weight allows industrial equipment to operate at lower power, saving resources. Best quality Forged Carbon Fiber Sheet - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Chile, Rwanda, Manila, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,