Bottom price Carbon Fiber Plate In Stock - OEM manufacturer custom cnc carbon fiber parts – Feimoshi

Bottom price Carbon Fiber Plate In Stock - OEM manufacturer custom cnc carbon fiber parts – Feimoshi Detail:

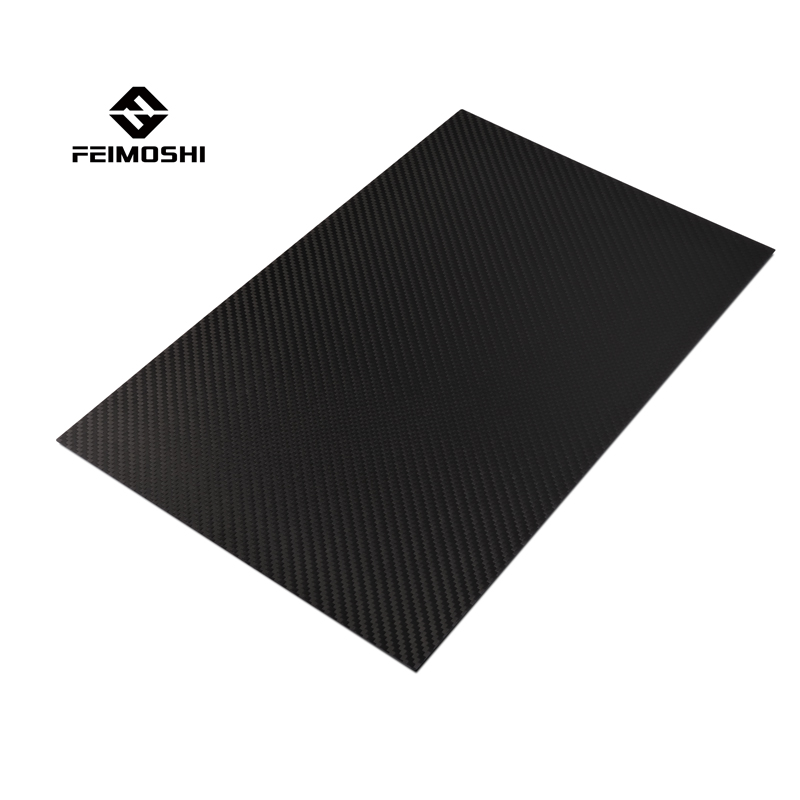

OEM manufacturer custom cnc carbon fiber parts

1. Base

CNC Machined Carbon Fiber Sheet parts is the mainstream environmental friendly new product of the century, it features high strength, abrasion resistant, weather-proof, waterproof, air-pervious.

2. Description

Features:

1. Very light and very strong.

2. Excellent durance.

3. Corrosion resistance.

4. Excellent planeness

5. Very flexible.

6. Nice appearance.

Application:

1. UAV, RC Toy model , Aeromodelling, Helicopter Model.

2. Electrical products.

3. Shipbuilding.

4. Space aviation defense.

5. Sports equipments.

6. Automobile parts.

7. Wind power blades.

8. Spinning Reels Brake Rotor friction plate, Rocker.

9.Medical device(X-ray, DR).

10. Etc.

FAQ

1) Could you do the CNC cutting?

Yes, we could do the CNC cutting for the carbon fiber material.

2) what is the format of the drawings you need?

DXF, DWG and step format are all fine.

3) What is the tolerance of CNC cutting?

About +/-0.2mm

4) What is the largest carbon fiber sheet for cutting?

1000X2500mm cutting is ok for us.

5) How many days for the cutting service?

Normally, it needs about 7-15 working days and it also depends on the order quantity.

Looking for ideal Carbon Fiber FPV Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Hobby Carbon Fiber are quality guaranteed. We are China Origin Factory of Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

4. Its maintenance function is good. Carbon fiber material is waterproof, resistant to high temperature, ultra-low temperature, and abrasion, and can be used in all harsh environments. Bottom price Carbon Fiber Plate In Stock - OEM manufacturer custom cnc carbon fiber parts – Feimoshi , The product will supply to all over the world, such as: Qatar, Guatemala, Luxemburg, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!