Cheap price Carbon Fiber Stand - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi

Cheap price Carbon Fiber Stand - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi Detail:

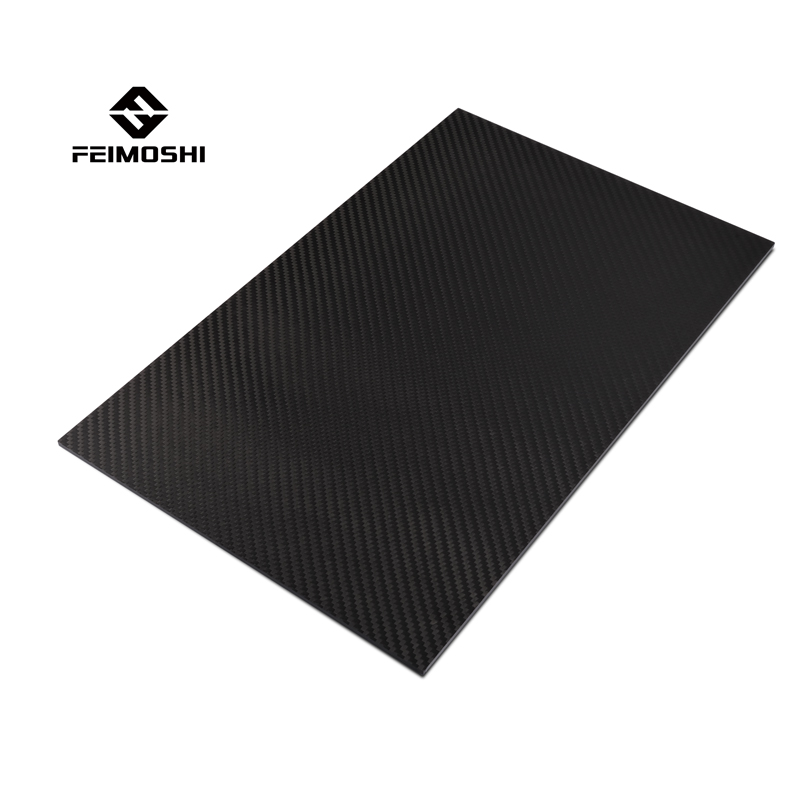

3K Carbon fiber Octagon tube square boom for handguard

Carbon Fiber Tube has light,high strength, wearable, and a very low CTE (coefficient of thermal expansion), moreover ,carbon fiber does not transfer heat as much as most metals.

One of the biggest benefits of using composite tubing in general is the ability of the material to resist weather much better than metals,because it will not corroded .

Our product widely uses in aviation, space flight, automobile, toy, kite, pens, handicraft, tent, windmill, umbrella, each kind of sports equipment and so on

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness: 0.5mm/1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Techniques: Rolling-wrapping

Advantage: High-Strength, light weight, Corrosion Resistant etc.

Service: Logo Service, CNC Cutting carbon fiber Service, Packing and assembly service

Many octagon full carbon tubes in stock, mixed order is welcome.

If any interesting in pls feel to contact us. We will do our best to support you.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal Carbon Fiber Square Tube for Sale Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Square Poles are quality guaranteed. We are China Origin Factory of Carbon Fiber Square Tube 6mm. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

1. The net weight of carbon fiber products is relatively light. The extraordinary light weight allows industrial equipment to operate at lower power, saving resources. Cheap price Carbon Fiber Stand - 3K Carbon fiber Octagon tube square boom for handguard – Feimoshi , The product will supply to all over the world, such as: Slovenia, Algeria, French, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.