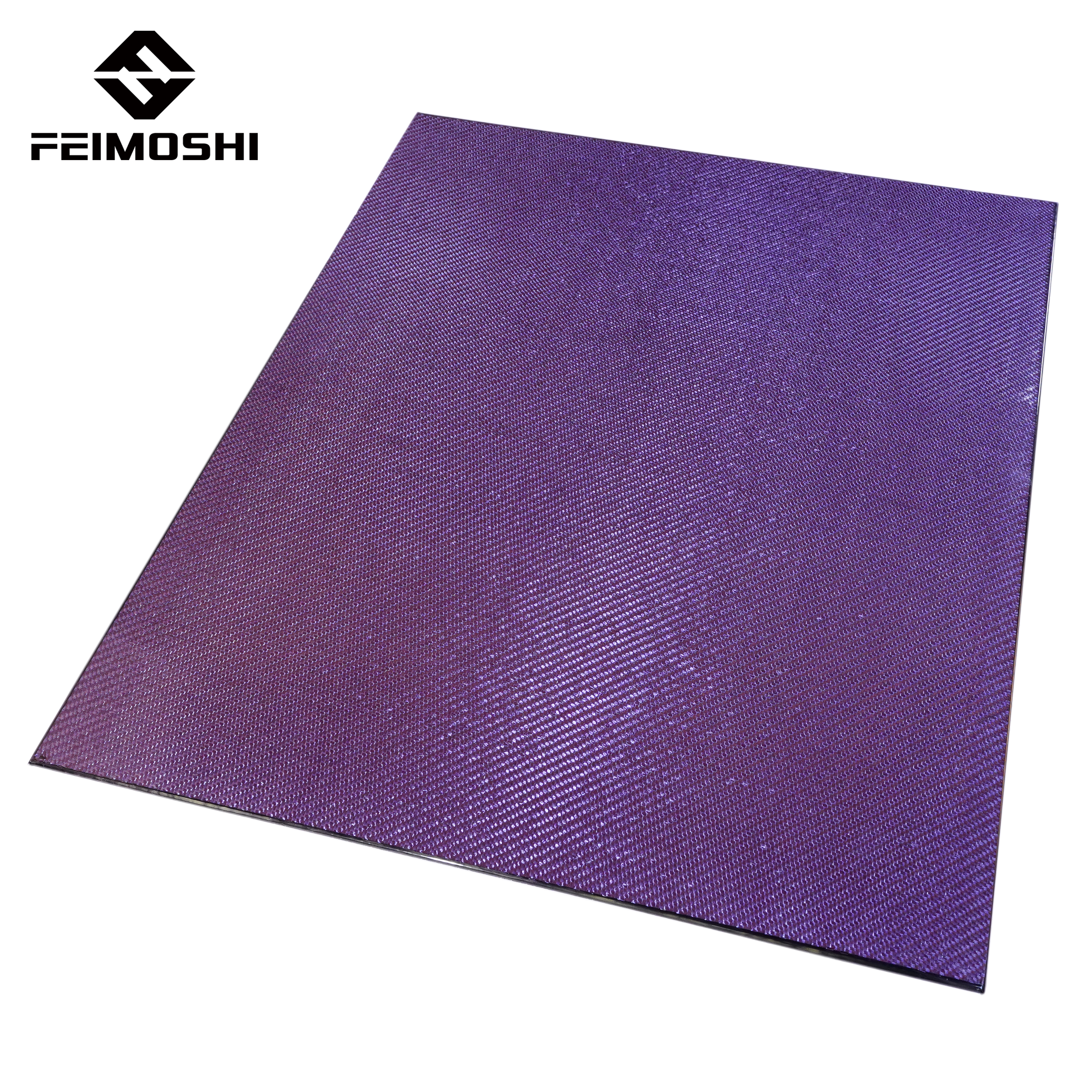

China Cheap price 3k Composite Plate - Hot sale 3k twill weave matte surface 400*500*0.2mm color carbon sheet fiber plate price – Feimoshi

China Cheap price 3k Composite Plate - Hot sale 3k twill weave matte surface 400*500*0.2mm color carbon sheet fiber plate price – Feimoshi Detail:

Product Description:

The Carbon Fiber Sheet or Carbon Fiber Plate is manufactured using 100% carbon fiber reinforcement and epoxy resin.

The surface can choose from will ain, matte/glossy. without any glass fiber contents. It is especially applicable for FPV frame, helicopters, and RC airplanes.

ain, matte/glossy. without any glass fiber contents. It is especially applicable for FPV frame, helicopters, and RC airplanes.

Product Feature:

100% 3K Carbon Fiber Strong Strength and Light Weight.

Perfect for any application including RC, drones, helicopters, etc.

The surface is cross grain, the nice surface without any glass fiber contents.

These carbon fiber sheets contain 100% carbon fiber imported from Japan.

It is especially applicable for Multicopter, Helicopter and RC airplanes.Product Application:1. Aerospace, RC model parts Helicopters Model Drone, UAVS

2. Decoration parts for Car and jewelry

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. Others

The Carbon Fiber Sheet or Carbon Fiber Plate is manufactured using 100% carbon fiber reinforcement and epoxy resin.

The surface can choose from will

Product Feature:

100% 3K Carbon Fiber Strong Strength and Light Weight.

Perfect for any application including RC, drones, helicopters, etc.

The surface is cross grain, the nice surface without any glass fiber contents.

These carbon fiber sheets contain 100% carbon fiber imported from Japan.

It is especially applicable for Multicopter, Helicopter and RC airplanes.Product Application:1. Aerospace, RC model parts Helicopters Model Drone, UAVS

2. Decoration parts for Car and jewelry

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. Others

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. China Cheap price 3k Composite Plate - Hot sale 3k twill weave matte surface 400*500*0.2mm color carbon sheet fiber plate price – Feimoshi , The product will supply to all over the world, such as: Armenia, Plymouth, United Kingdom, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Send your message to us:

Write your message here and send it to us