Factory Supply Carbon Fiber Opener - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi

Factory Supply Carbon Fiber Opener - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi Detail:

Lightweight phone case carbon fiber shockproof and anti-drop

Below is the newest iPhone 13 cases:

1. Material: Kevlar Fiber

2. Technology: Vacuum Pumping by Autoclave equipment

3. Weight: as light as you thought

4. MOQ: 10pc

5. Matte surface, no sweats, no fingerprints;

6. 4-side protection, camera lens protection;

7. Excellent grip, no loose;

8. 1:1 precise cutouts for ports and buttons;

9. Like a skin, keep the original beauty/feeling of the device

Why do we use aramid fiber, but don’t use carbon fiber?

Aramid fiber is commonly used in aerospace and performance automotive industries, as it is exceptionally durable and lightweight.

Different from carbon fiber, aramid fiber does not affect your phone’s signal (Wi-Fi, GPS, and cell reception), making it the ideal material for phone cases.

Using vacuum forming technologies, we can mold aramid fiber into a multitude of designs while maintaining its strength and protective qualities.

Product detail pictures:

Related Product Guide:

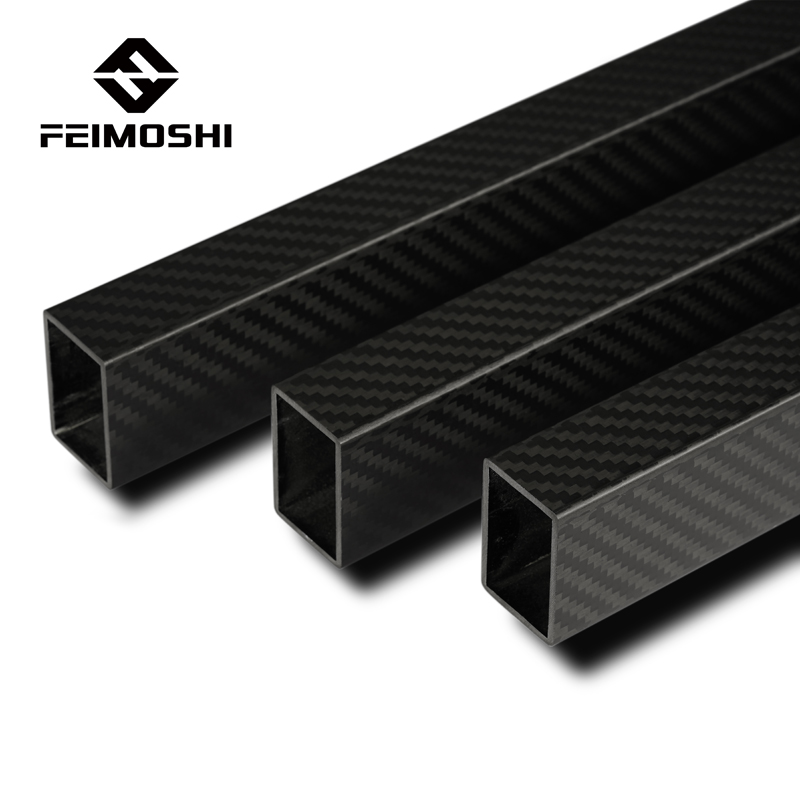

In the automotive industry, carbon fiber sheets are used to strengthen automotive components such as doors, hoods, bumpers, fenders and roof rails. Automakers often use steel to make these parts. Although less expensive, steel is much heavier than carbon fiber. To make vehicles such as race cars lighter, carbon fiber sheets are often used to replace many steel parts. Factory Supply Carbon Fiber Opener - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi , The product will supply to all over the world, such as: Leicester, Switzerland, Frankfurt, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.