China Cheap price Composite Part - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi

China Cheap price Composite Part - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi Detail:

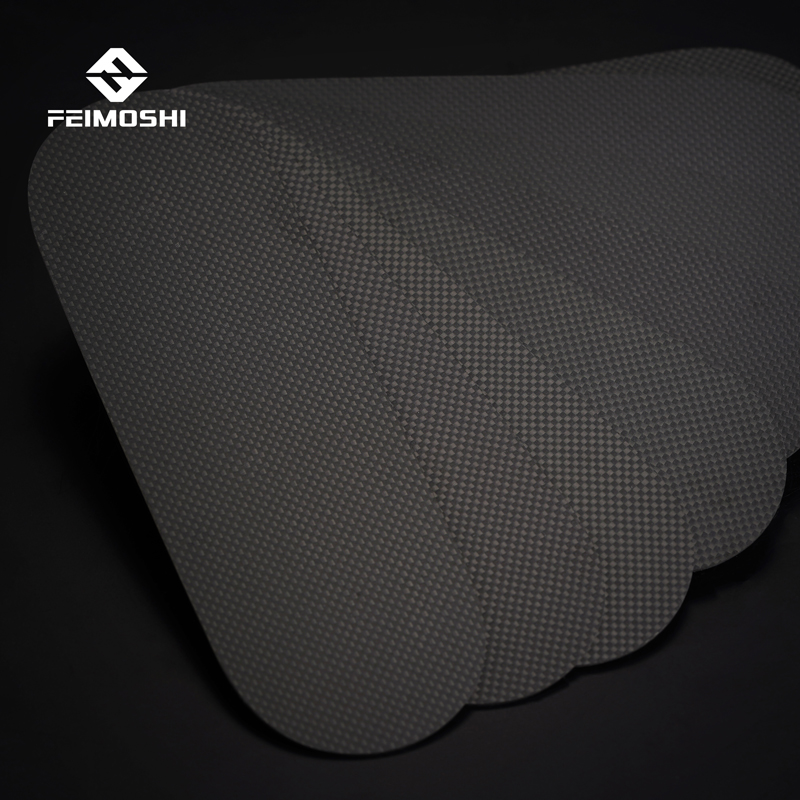

CNC cutting Carbon fiber Structural Shapes plate

CNC cutting carbon fiber accessories could be widely used in FPV drone, Medical, Industury, building construction. We have many branded customers to make their products more professional and get a good feedback for the carbon fiber material. We could do the thick carbon fiber sheet, like 0.3mm, 1.0mm, 2.0mm….6.0mm, 10.0mm, 20.0mm and so on. We have professional workers to do the thick carbon fiber sheet cutting. And it solves many problems when using in construction, furniture, ect.

Carbon fiber chamfer, carbon fiber countersunk and carbon fiber drilling are also ok for us.

Meantime, we have various size carbon fiber tube, shaped carbon fiber parts service and offer the OEM/ODM service for you.

FAQ

Q1. How many years in this industry?

A: We specialized in this line for many years and got lots of satisfied feedback from branding businesses.

Q2: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: What is the lead time?

A: Sample needs 1-3 days, mass production needs 10-15 days, also according to the order volume.

Q4: Do you have any MOQ limit?

A: No MOQ for instock parts and 2000pcs for non-stock products.

Q5: Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc

Q6: How do you ship the goods and how long does it take arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Looking for ideal OEM Service Manuals Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Service First OEM are quality guaranteed. We are China Origin Factory of Amazon OEM Service. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. China Cheap price Composite Part - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi , The product will supply to all over the world, such as: Guatemala, Indonesia, Rio de Janeiro, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly