China OEM Custom Carbon Fiber Card - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi

China OEM Custom Carbon Fiber Card - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi Detail:

Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max

The ultra-thin autoclave kevlar phone case is on sale. Its main features are thinness, toughness, high-quality appearance, and comfortable touch.

Material: autoclave kevlar

Thickness: 0.35mm ultra thin

Finish: autoclave process

MOQ: 10pcs

Color: black, red, blue

Shipping methods: Express services like DHL, UPS, FedEx, TNT, or Air shipping, Sea shipping

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

Note: We support free sample service!

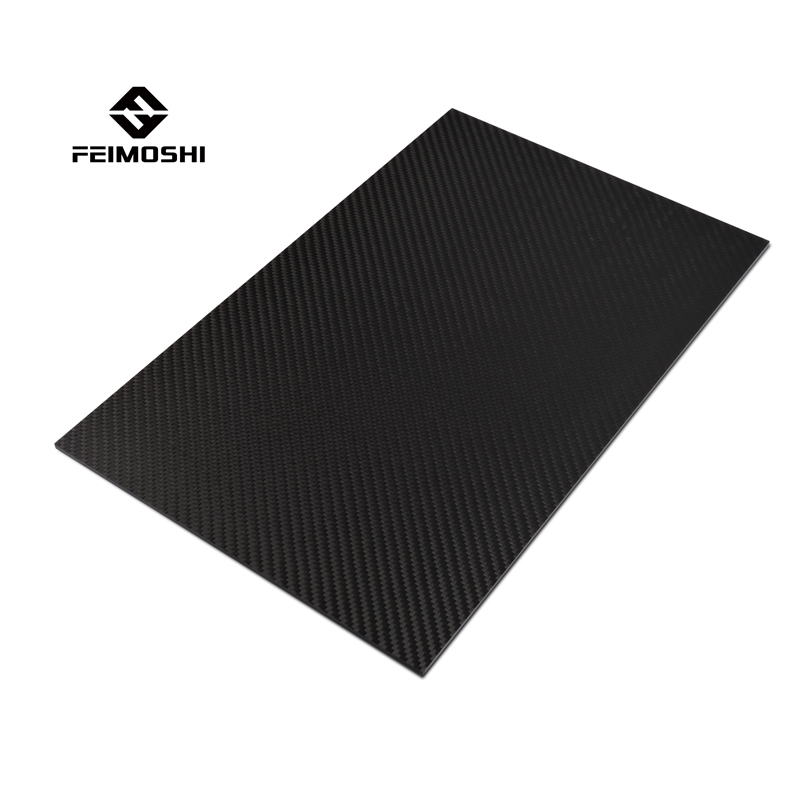

Product detail pictures:

Related Product Guide:

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. China OEM Custom Carbon Fiber Card - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi , The product will supply to all over the world, such as: Uzbekistan, Saudi Arabia, Portugal, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.