China wholesale Composite Cut - Factory High precision carbon fiber CNC cutting machining parts – Feimoshi

China wholesale Composite Cut - Factory High precision carbon fiber CNC cutting machining parts – Feimoshi Detail:

Factory High precision carbon fiber CNC cutting machining parts

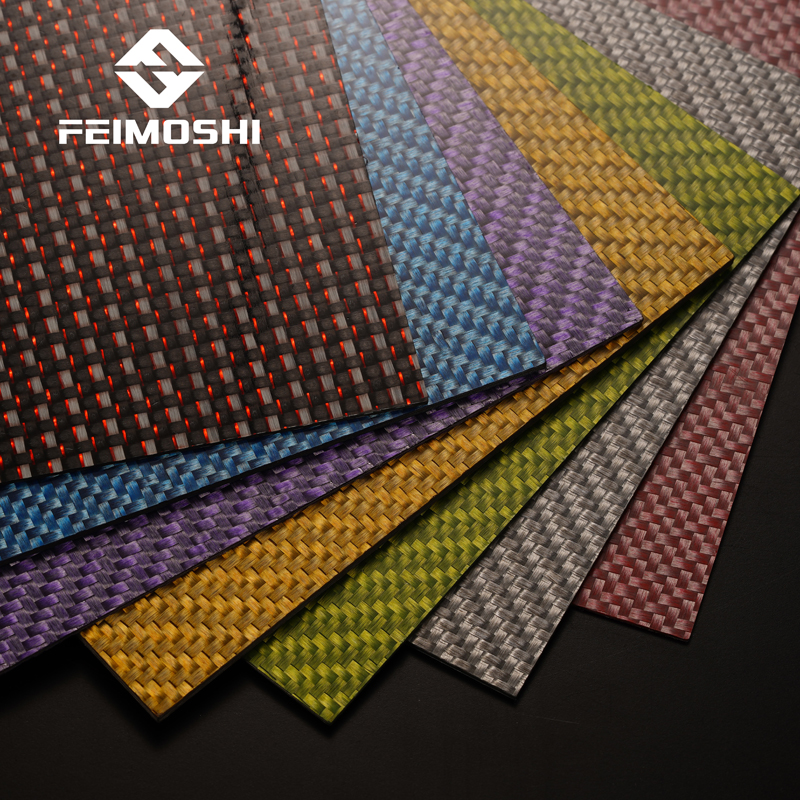

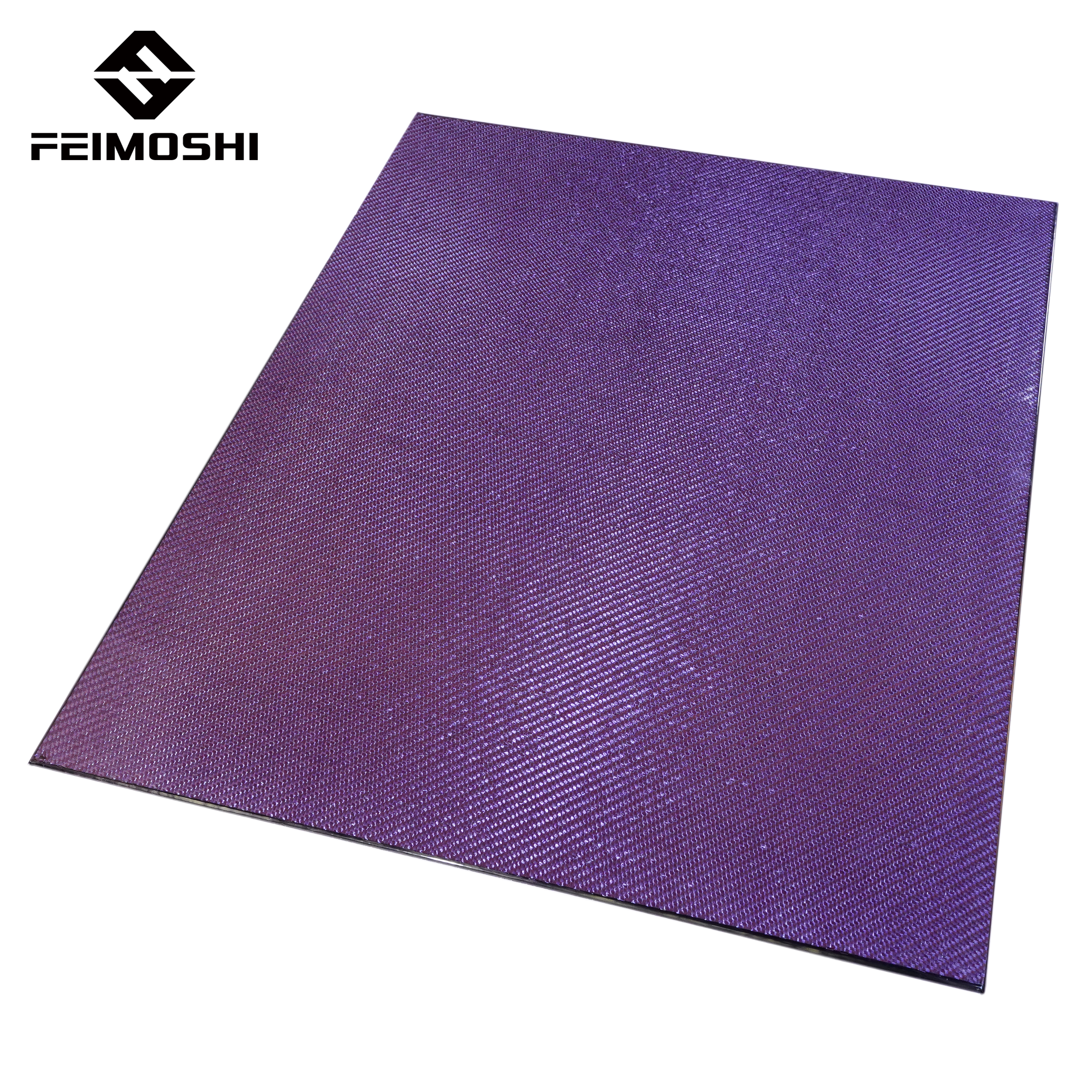

Our carbon fiber plate is made with 100% high-quality carbon fiber. It is the same materials used to make modern rockets and spacecraft. It is lightweight, durable, and designed to handle the extreme conditions of space travel.

Our carbon fiber panel is perfect for any application where strength and weight are important, from drone frames to automotive and motorcycle parts. It also has a high-tech look and recognizable appearance that works well as a veneer to cover another material.

We stock various sizes and thicknesses as shown below. For custom sizes or cuts please contact us, we also offer carbon fiber manufacturing and CNC machining services for custom parts.

1. who are we?

We are based in Guangdong, China, start from 2011,sell to North America(00.00%),Domestic Market(00.00%),Western Europe(00.00%),South America(00.00%),Eastern Europe(00.00%),Southeast Asia(00.00%),Mid East(00.00%),Eastern Asia(00.00%),Southern Europe(00.00%),Oceania(00.00%),Central America(00.00%),Northern Europe(00.00%),South Asia(00.00%).

2. how can we guarantee the quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

3K Carbon Fiber Tubes, Carbon Fiber Rod,3K Carbon Fiber Sheet, Carbon Fiber Parts, Fiberglass Tube

4. what services can we provide?

Accepted Delivery Terms: EXW,Express Delivery;

Accepted Payment Currency:USD,HKD,CNY;

Accepted Payment Type: T/T,PayPal;

Language Spoken:English,Chinese

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. China wholesale Composite Cut - Factory High precision carbon fiber CNC cutting machining parts – Feimoshi , The product will supply to all over the world, such as: Sri Lanka, Colombia, New Zealand, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!