Chinese wholesale Drill Carbon - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi

Chinese wholesale Drill Carbon - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi Detail:

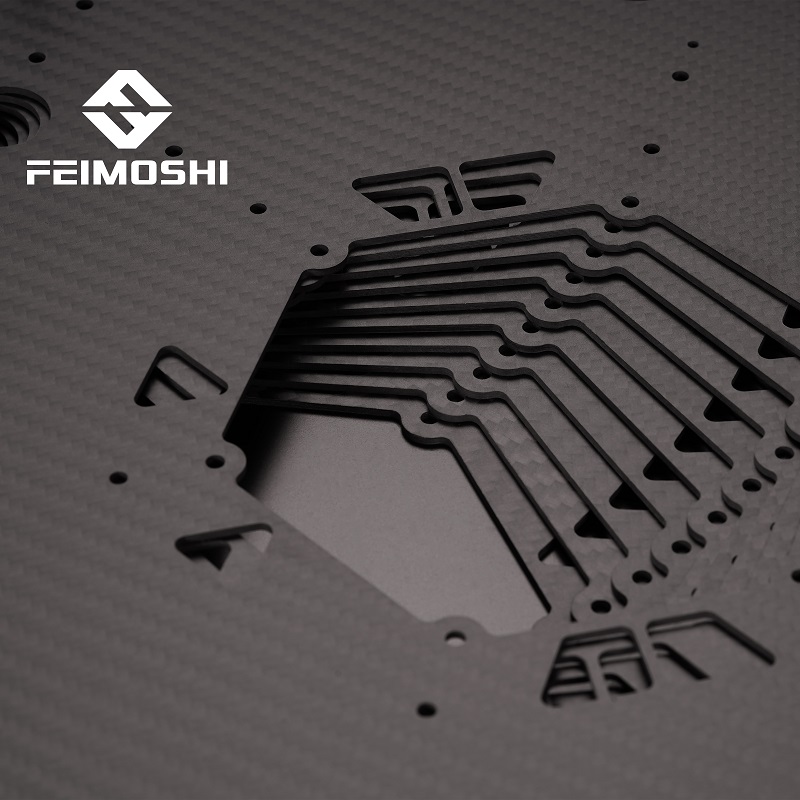

CNC Cutting 3K Carbon Fiber Sheet Plate

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

More quantity, more competitive price for your FPV frame.

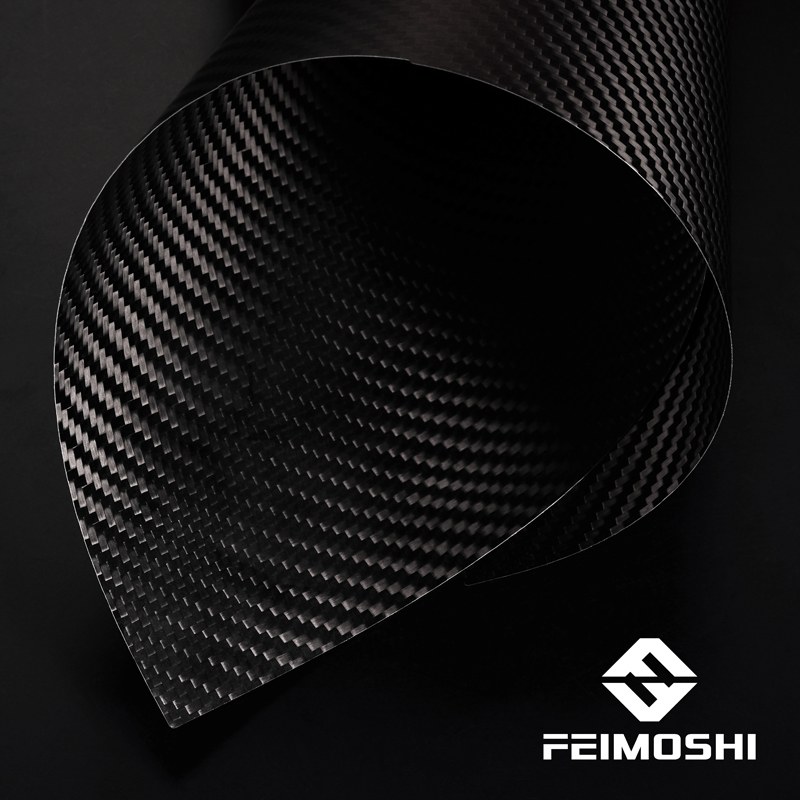

We produced the carbon fiber plate by the carbon fiber cloth.

Carbon fiber cloth is similar to cloth, light in weight, thin in thickness, and soft in texture. It can be cut at will and is woven from carbon filaments. The thickness of carbon fiber cloth is 0.167mm for 300g and 0.111mm for 200g. It is suitable for the treatment of increasing building load, changing the function of engineering use, material aging, concrete strength grade lower than the design value, structural crack treatment, service component repair and protection in harsh environments. And it can greatly help the structure in terms of shear resistance, seismic resistance and bending resistance. In use, it can be pasted in multiple layers according to engineering design requirements. It is recommended that no more than 4 layers are used. Because carbon fiber is posted in multiple layers at the same time, the tension attenuation will cause waste.

Looking for ideal Carbon Fiber 10mm Plate Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 3K Carbon Fiber Sheet Plate are quality guaranteed. We are China Origin Factory of Carbon Fiber 60 Keyboard Plate. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Chopped carbon fiber has high strength, high modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, good electromagnetic shielding, and does not swell or swell in organic solvents, acids and alkalis. Excellent corrosion resistance. Chinese wholesale Drill Carbon - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi , The product will supply to all over the world, such as: British, Milan, Panama, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.