Excellent quality Carbon Fiber Rectangular Tube – custom 15mm 3K twill matte carbon fiber tubes – Feimoshi

Excellent quality Carbon Fiber Rectangular Tube – custom 15mm 3K twill matte carbon fiber tubes – Feimoshi Detail:

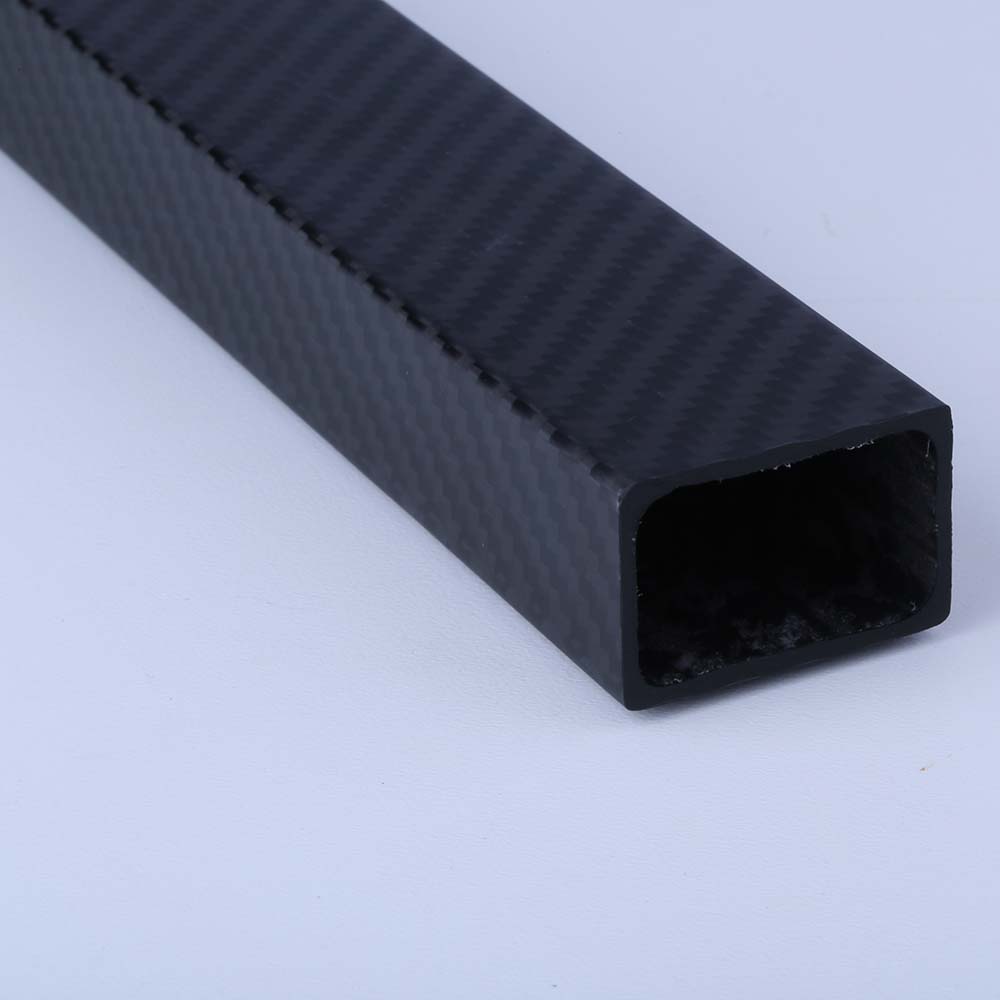

custom 15mm 3K twill matte Carbon Fiber Tubes

Carbon tube/pipe features:

1. Introduction

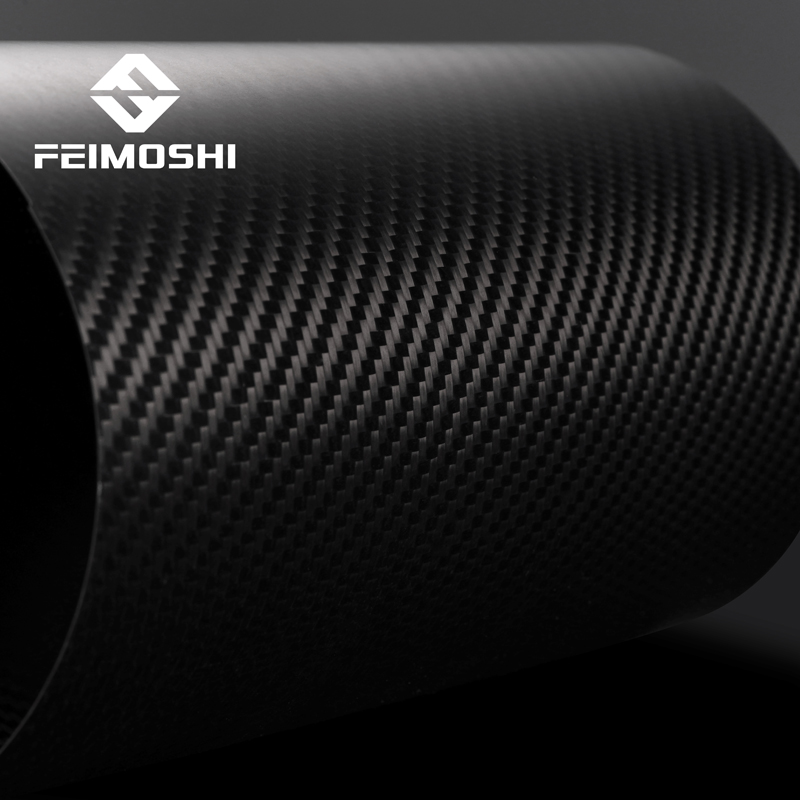

These 3K Carbon Fiber Tube are made of pure carbon fiber with beautiful twill or plain weave; Available in different colors and sizes( usually 3K twill matte); Customized Round carbon fiber tubes specs are accepted,like Outer Diameter :6mm,8mm,10mm,12mm,14mm,16mm20mm,22mm,25mm,30mm……350mm;

Customized Shaped Full Carbon Fiber Tube: such as: 20X30mm, 30X30mm or others. Thickness: 1.0mm, 1.5mm, 2.0mm or other thickness.

Square carbon fiber tube: 10X10mm, 15X15mm, 18X18mm, 20X20mm, 30X30mm square carbon fiber tube(These tubes have the mould by us)

Recently we upgrade our machines to improve the carbon fiber tube precision.

Most precise tolerance shaped carbon fiber tubes for us.

2. Specifications

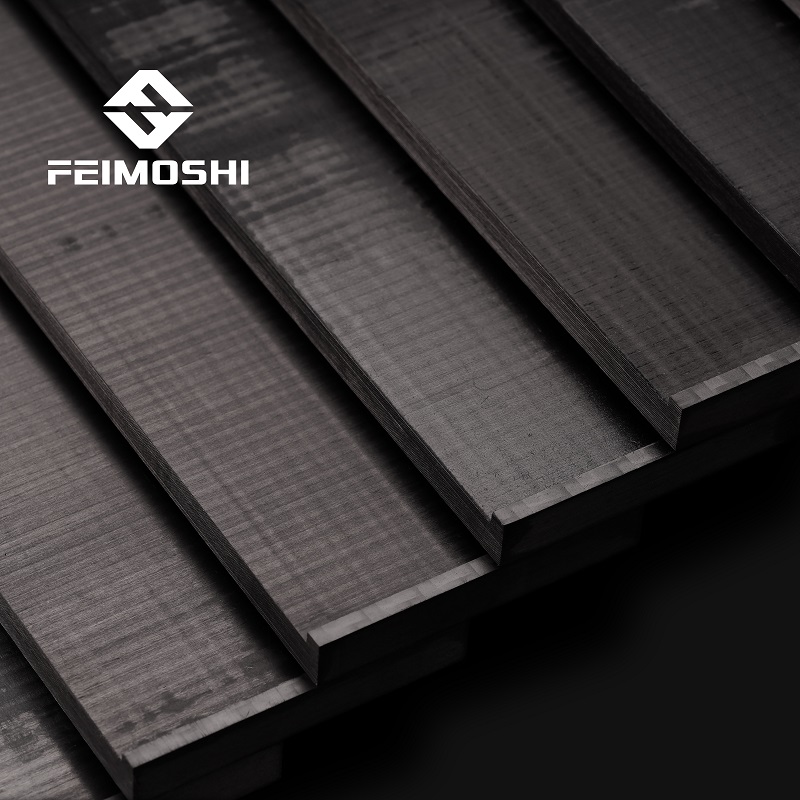

1) High temperature resistance carbon fiber tubes :100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

The carbon fiber tube is light in weight and high in strength. It can be applied to different parts of the drone body during design and assembly, such as the arm and wing frame. Compared with aluminum alloy material, it can increase the weight reduction effect by 30%, which can improve the aircraft, endurance and increase load capacity. The carbon fiber material itself has high tensile strength, energy absorption, shock resistance, and good corrosion resistance, which also extend the service life of the UAV.

Product picture

Looking for ideal 15mm Matte Carbon Fiber Tubes Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 15mm Twill Matte Carbon Fiber Tubes are quality guaranteed. We are China Origin Factory of Custom 3K Carbon Fiber Tubes. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Excellent quality Carbon Fiber Rectangular Tube – custom 15mm 3K twill matte carbon fiber tubes – Feimoshi , The product will supply to all over the world, such as: Rotterdam, United States, Armenia, With the improvement of the production process, carbon fiber board will popularize or replace many metal structural materials, providing the possibility for the lightness and convenience of products.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.