factory Outlets for Chamfering Carbon Fiber Cut - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi

factory Outlets for Chamfering Carbon Fiber Cut - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi Detail:

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

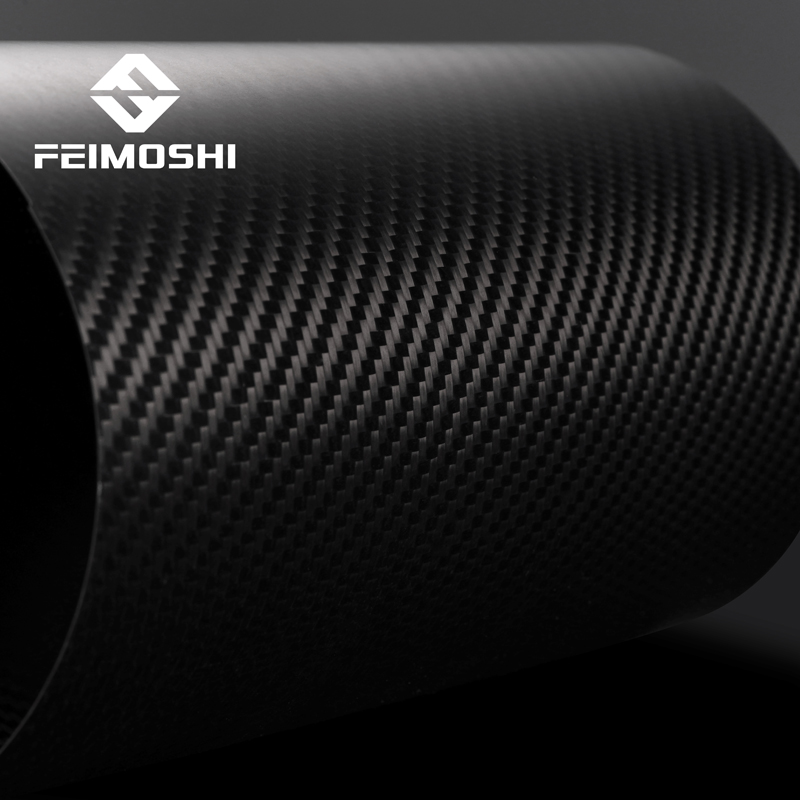

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

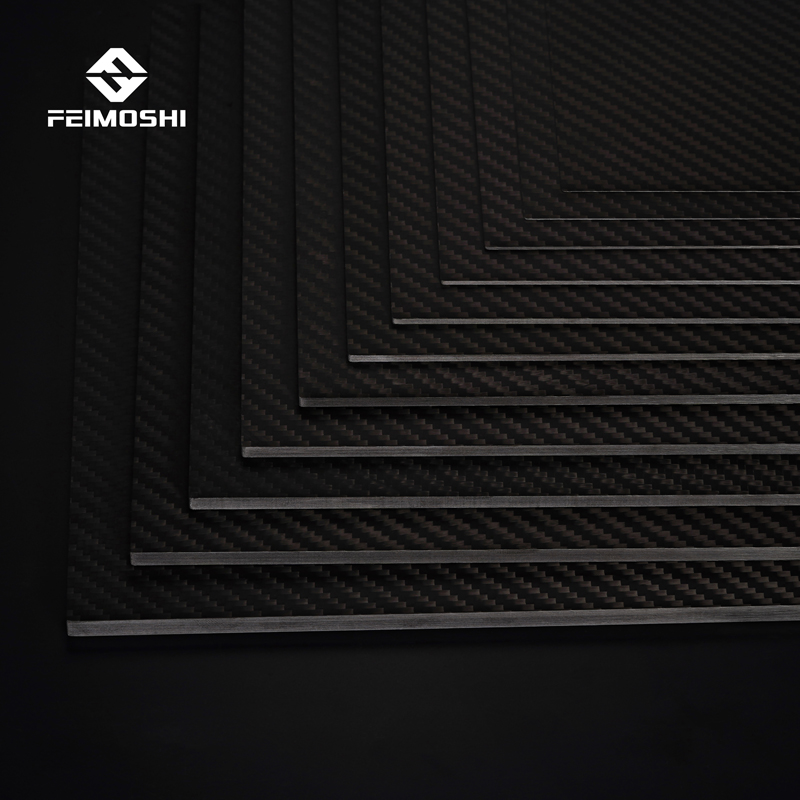

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Protective Cases – aramid Bullet-Proof Material – Wireless Charging Capable – Slim, Drop Protection – Textured, Non-Scratch Shell

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

Product detail pictures:

Related Product Guide:

Carbon fibers are generally not used alone, but in the form of composite materials. Composite material refers to a new type of material with certain special functions and structures formed by combining two or more materials. The material composition can be generally understood as matrix material + reinforcement material, among which the matrix material is mostly resin, ceramic, metal, Rubber and other materials, the reinforcing material is often glass fiber or carbon fiber. factory Outlets for Chamfering Carbon Fiber Cut - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi , The product will supply to all over the world, such as: Islamabad, Bangladesh, Iceland, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Send your message to us:

Write your message here and send it to us