Factory Supply Cnc Laser Cutting - 0.3-20mm thick CNC Cut 3K Carbon Fiber Sheet Plate – Feimoshi

Factory Supply Cnc Laser Cutting - 0.3-20mm thick CNC Cut 3K Carbon Fiber Sheet Plate – Feimoshi Detail:

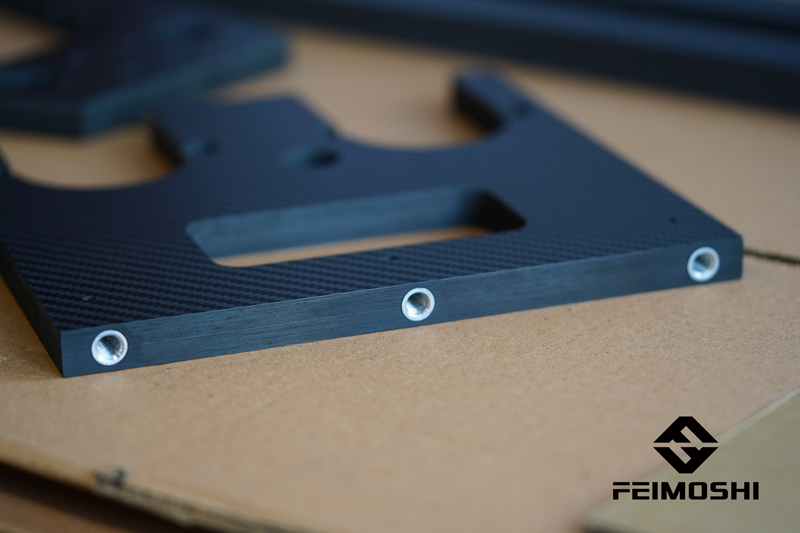

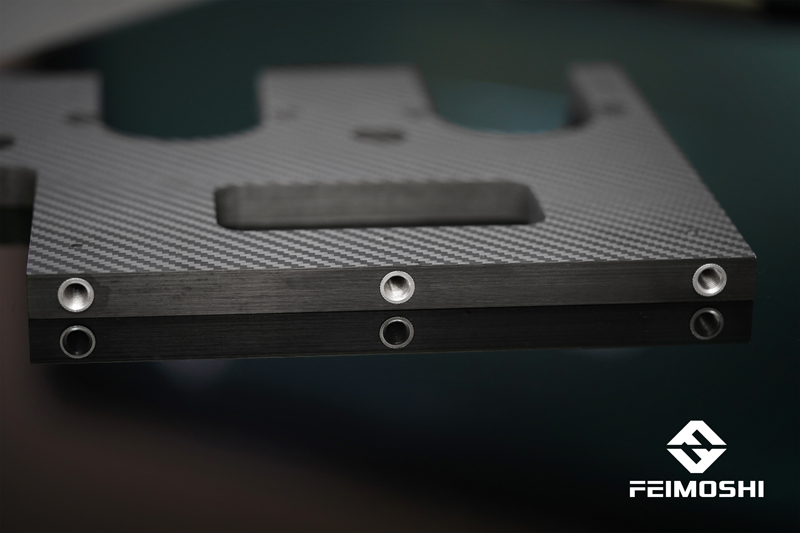

Model No.: Carbon fiber cutting accessories

Shape: Carbon Fiber Plate for cutting

Performance: High-Strength and Light weight

Mechanical Property: High-Performance Type

Transportation: DHL/Fedex/EMS/HK post/Epacket or others

Place of Origin: Shenzhen

Payment Type: T/T, Paypal.

Incoterm: FOB, CFR, EXW

Delivery Time: 7-15 working Days

Carbon fibers are usually combined with other materials to form a composite. When combined with a plastic resin and wound or molded it forms carbon-fiber-reinforced polymer (often referred to as carbon fiber) which has a very high strength-to-weight ratio, and is extremely rigid although somewhat brittle. However, carbon fibers are also composited with other materials, such as graphite to form carbon-carbon composites, which have a very high heat tolerance.

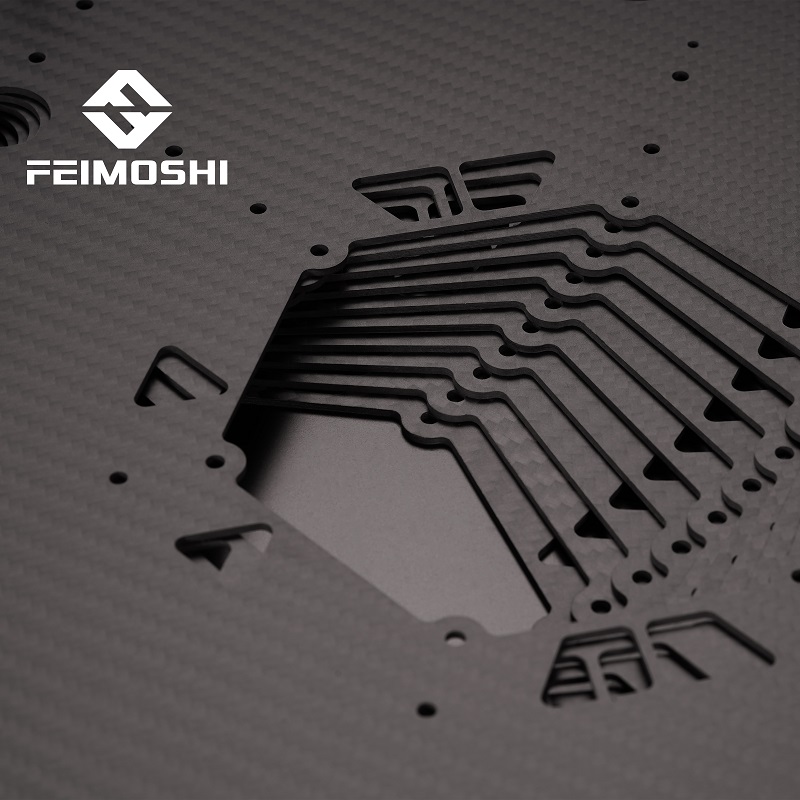

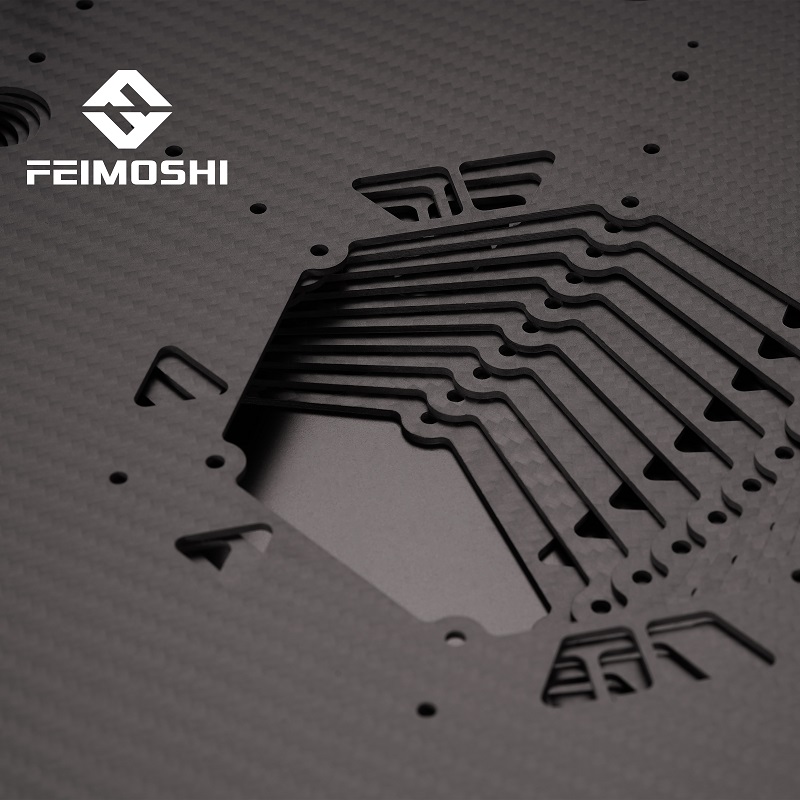

Carbon Fiber Sheet is high strength and extremely lightweight. It is the most commonly used composite fabric with applications in all areas of industry, such as household applications, machines, aerospace, spaceflight, and other high-tech applications. Carbon Fiber sheet has super knitting technology and exact molding technics and equipment, so we can produce full Carbon series products to meet all kinds of process requirements on composite materials.

Product Description

Material: Carbon fiber part Size :Customized (welcome to customeied)

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plate are in stock(400X500mm or 500X600mm)

Service: OEM & ODM,Cnc Cutting Service And Logo Printing

Looking for ideal CNC 3K Carbon Fiber Sheet Manufacturer & supplier ?

A: We have a wide selection at great prices to help you get creative. All the 3K Carbon Fiber Sheet Plate are quality guaranteed. We are China Origin Factory of CNC Cutting Carbon Fiber Sheets. If you have any question, please feel free to contact us.

Looking for ideal 100% Carbon Fibe Manufacturer & supplier ?

A: We have a wide selection at great prices to help you get creative. All the Low Price CNC Cutting are quality guaranteed. We are China Origin Factory of Custom Cnc Cutting Service. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. Factory Supply Cnc Laser Cutting - 0.3-20mm thick CNC Cut 3K Carbon Fiber Sheet Plate – Feimoshi , The product will supply to all over the world, such as: Adelaide, Vietnam, Serbia, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.