PriceList for Composite Drone Frame - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi

PriceList for Composite Drone Frame - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi Detail:

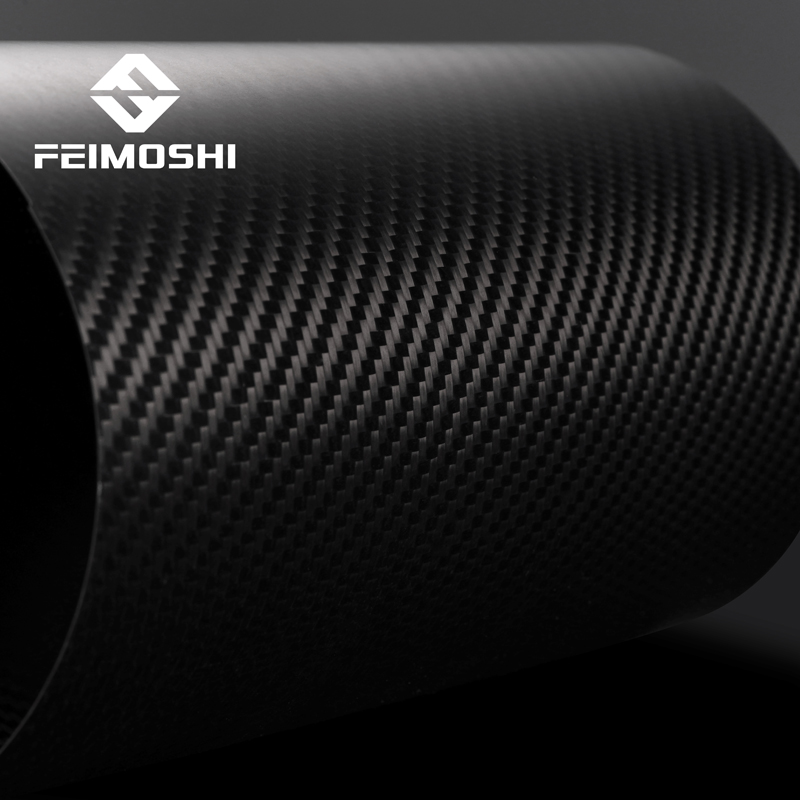

T700 3K Full Carbon Fiber Sheet

T700S is the highest tensile strength, standard modulus carbon fiber available in the industry. Standard modulus carbon fibers are available in tow sizes from 1K to 24K.

3K is recognized as the most delicate surface for fpv frames.

Our normal stock of sheets including full Carbon Fiber Sheets, Carbon Glass Sheet and G10 Glass Fiber Sheet.

T700 carbon fiber plate, toray carbon fiber, 3k carbon fiber sheets ,Carbon Fiber Sheet Product one of the most pouplar sheets.

Our normal stocked type is Toray T300 full carbon fiber sheet, carbon fiber tube, CNC cutting service, OEM/ODM and logo service.

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

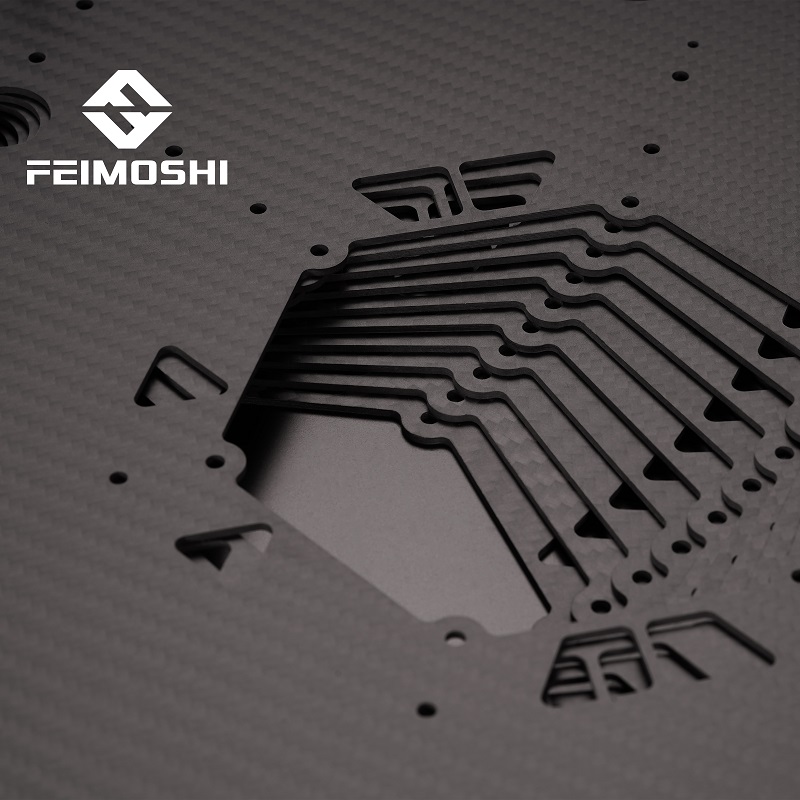

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for tesing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing.

Looking for ideal T700 Carbon Fiber Plate Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Toray Carbon Fiber are quality guaranteed. We are China Origin Factory of 3k Carbon Fiber Sheets. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

2. Low thermal expansion coefficient. A low coefficient of expansion is beneficial for improving the accuracy of the company's products. PriceList for Composite Drone Frame - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi , The product will supply to all over the world, such as: Yemen, Mecca, Swiss, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.