Factory Supply Solid Composite Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi

Factory Supply Solid Composite Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi Detail:

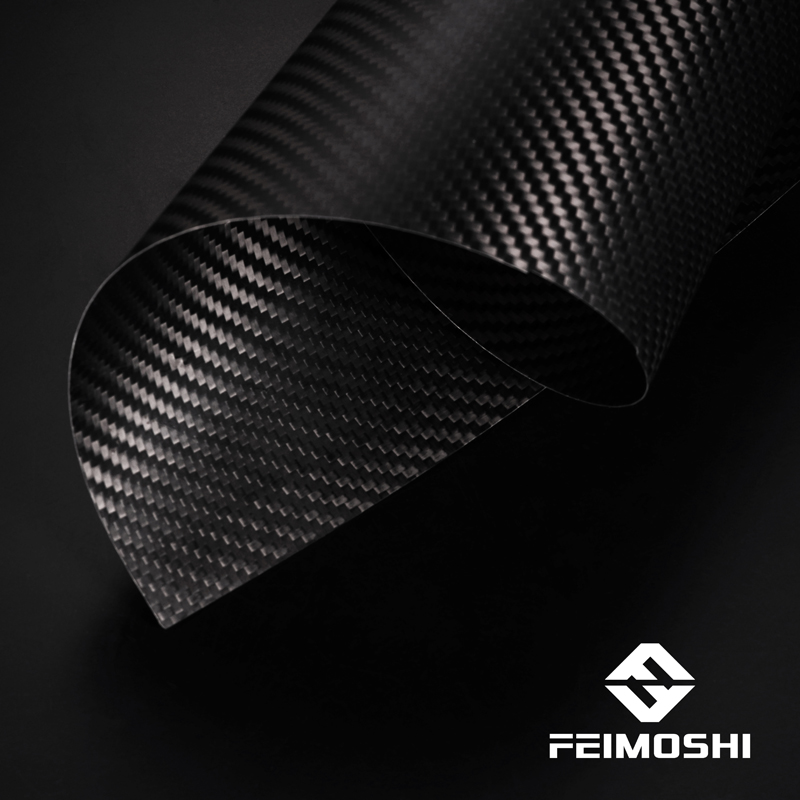

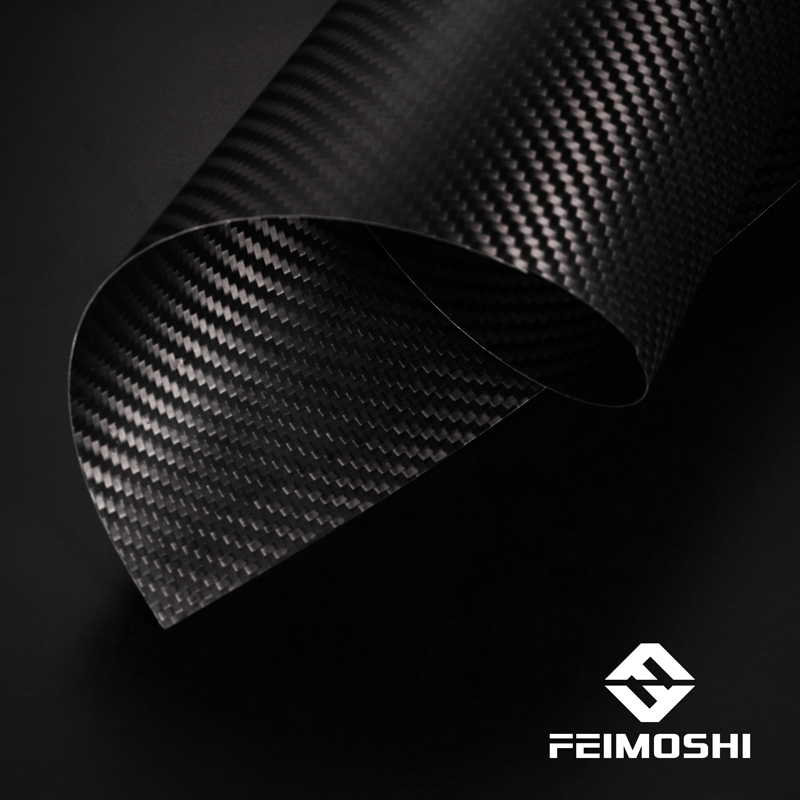

0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet

Carbon fiber is a new kind of high strength and high modulus fiber material with more than 95% carbon content.

Carbon fibers are flexible and rigid with outstanding mechanical performance.

The tensile strength of carbon fibers is several times that of steel.

Carbon fiber has 0.2mm-30mm thickness and 0.2-0.5mm thick plate is rigid and flexiable. And it could make the customers more creative.

You could inform me your ideal and we will help you to make it come true.

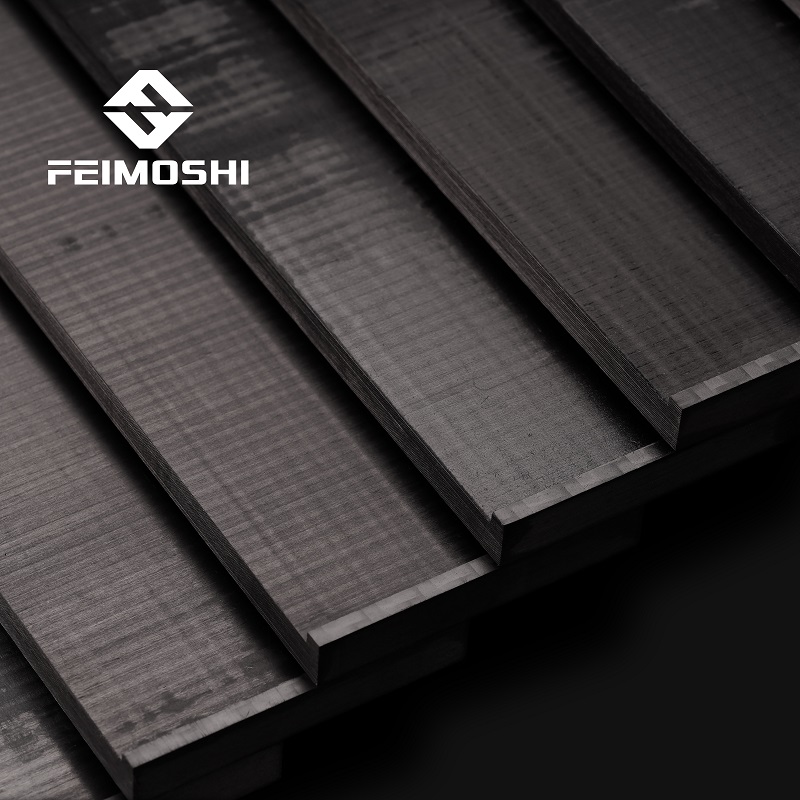

20mm-30mm thick plate is very rigid and strong to take the high weight of goods. It could use in building construction.

Different thickness has the various function for our daily life.

FAQ

1) Do you have the rigid and flexiable carbon fiber board?

Yes, 0.2mm-0.3mm thick is better choice for your using.

2) Do you have MOQ requirement?

No MOQ requirements and sample order is ok for us.

3) How many days for the customized carbon fiber plate?

Normally, 5-7 working days for the plate production.

4) which shipping way do you use?

DHL/Fedex/TNT/EMS/Epacket

5) Paypal is ok?

Yes, Paypal and T/T are both fine.

Looking for ideal UD 3K Twill Carbon Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Laminate Crp Sheets are quality guaranteed. We are China Origin Factory of Drone Frame Cnc Cutting Carbon Fiber. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. Factory Supply Solid Composite Plate - 0.2mm 0.3mm 3k plain twill carbon weaving carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Norwegian, Montreal, Norway, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.