Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi

Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi Detail:

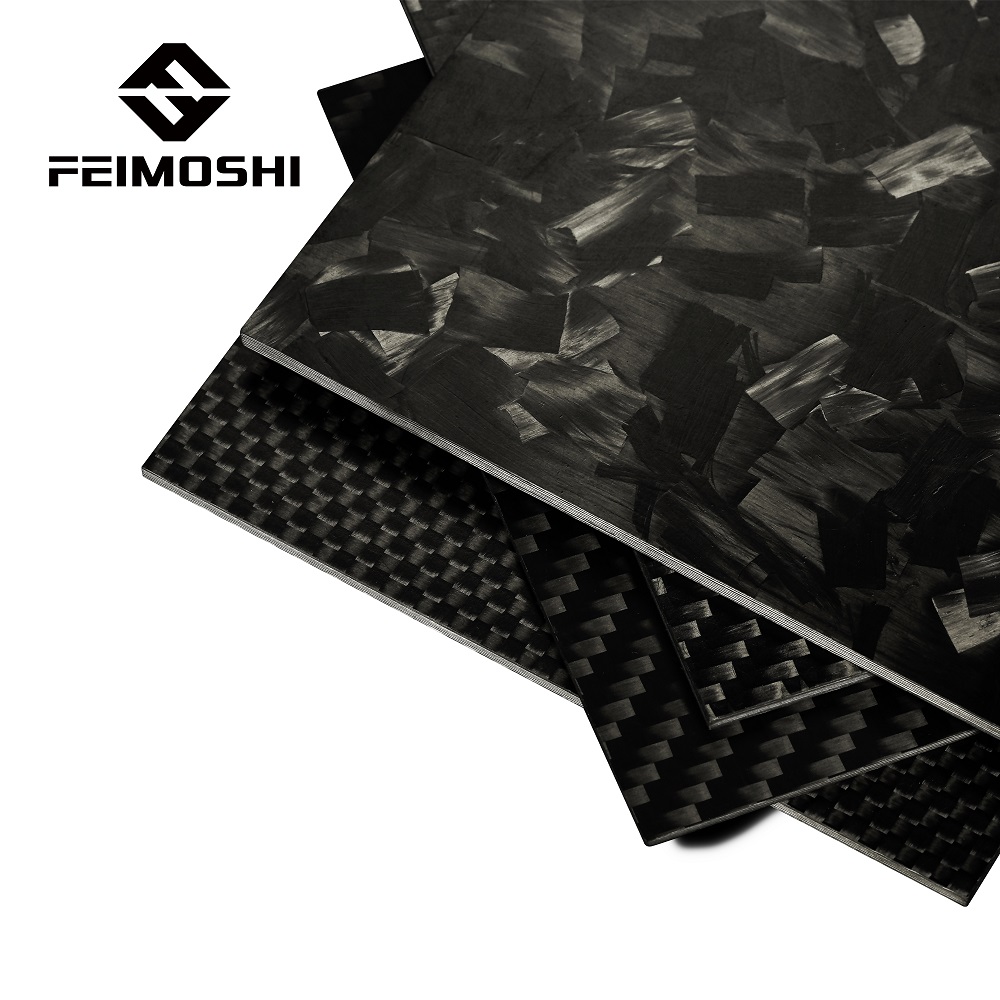

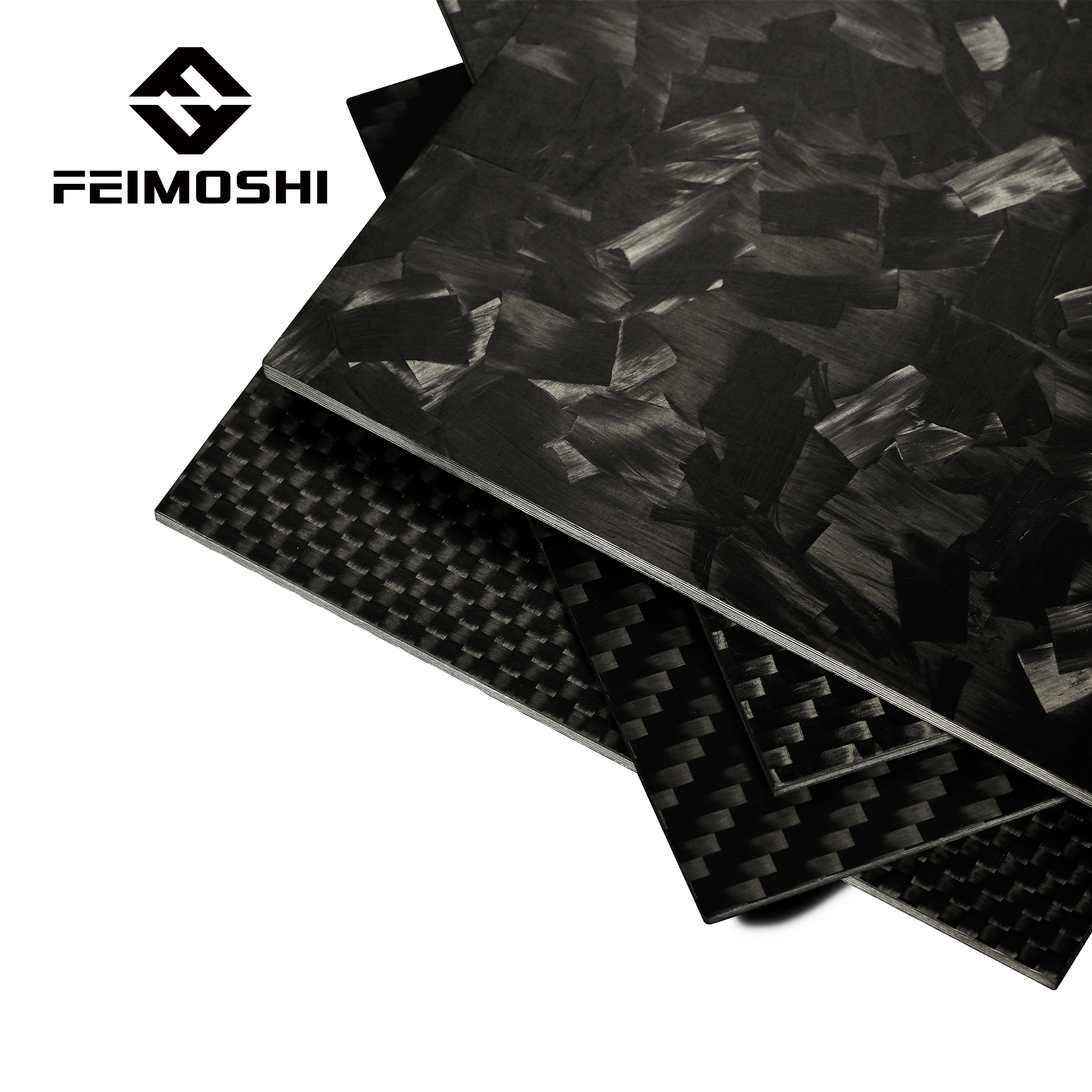

Forged carbon composite carbon fiber fabric custom forged plate

roduct Description:

The Forged Carbon Fiber Sheet or Forged Carbon Fiber Plate is manufactured using 100% carbon fiber reinforcement and epoxy resin. The surface can choose from will /plain, matte/glossy. without any glass fiber contents. It is especially applicable for FPV frames, helicopters, and RC airplanes. We are able to do Carbon Fiber CNC cutting Parts for RC Helicopter, RC cars, UAV frame, drone frame, multi-copter frame, camera gimbal frame or others per your specifications. Our factory use imported Japan TORAY or Taiwan TAIRYFIL carbon fiber fabric to make the carbon fiber plates/carbon fiber sheets.

Product Feature:

Strengthening material for C/C compound material;

High strength, lighter weight, imported raw material from Taiwan and Japan;

Filtration material under high temperature and for caustic liquid;

Electric conduct material, electrode & Static electricity resistance.

Product Application:

1. Aerospace, RC model parts Helicopters Model Drone, UAVS

2. Decoration parts for Car and jewelry

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi , The product will supply to all over the world, such as: Costa rica, Nicaragua, El Salvador, At the time of winding, the carbon fiber should be stable and not deviated, and the surface of the mandrel should be uniformly and continuously covered. Arranged according to a certain law, so that adjacent chemical fibers are neither easy to overlap nor have gaps, this law is called "winding law". The winding laws are different, and the quality of the carbon fiber pipes is also different. The proper design of the winding shape can ensure the quality of the carbon fiber pipes.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.