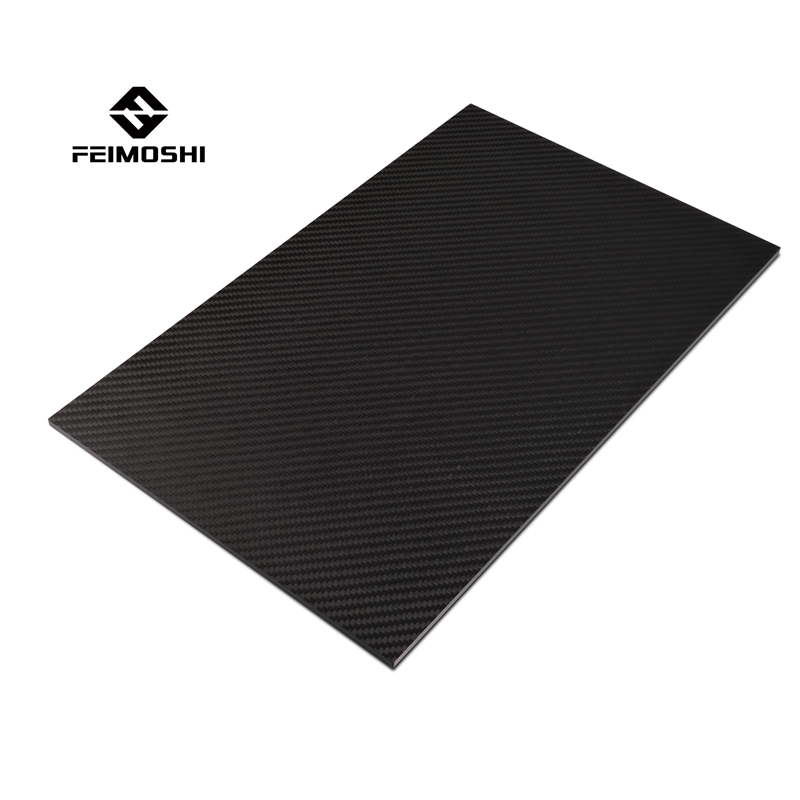

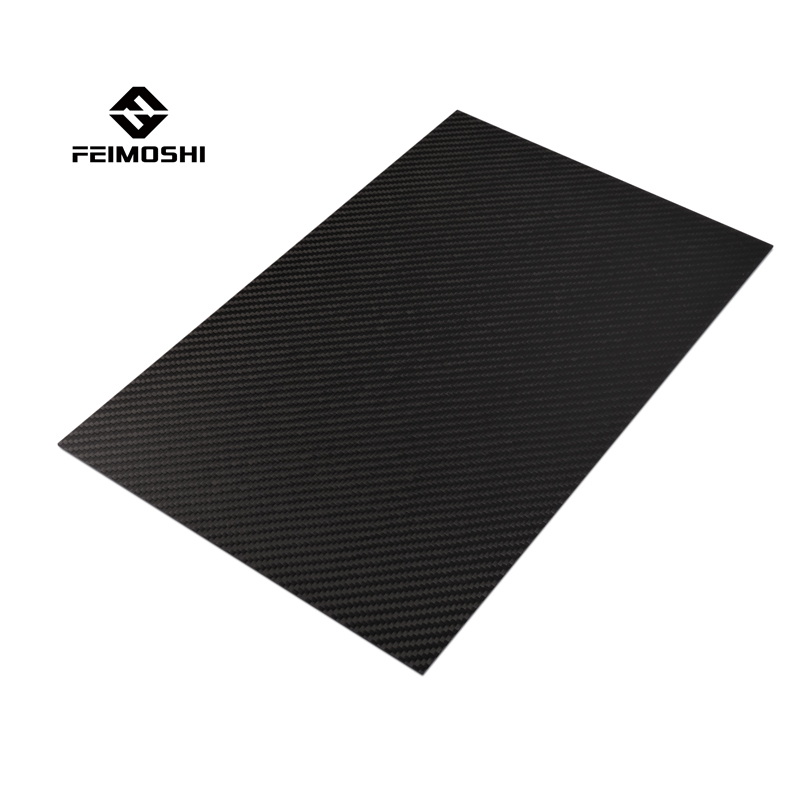

Good quality 20mm Carbon Fiber Plate - 2mm 6mm 10mm uav carbon fiber sheet/plate/board – Feimoshi

Good quality 20mm Carbon Fiber Plate - 2mm 6mm 10mm uav carbon fiber sheet/plate/board – Feimoshi Detail:

2mm 6mm 10mm uav carbon fiber sheet

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for OEM Customized plate. Customizing1000mm* 1mm Carbon Fiber Plate Carbon Fiber Sheet and any communication in anytime is ok for us. We sincerely welcome prospects all around the world to call us for business enterprise cooperation.

OEM Customized feimoshi Carbon Plate——We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

We are professional carbon fiber company. 100% carbon fiber plate, 100% carbon fiber tube and other customized shaped carbon fiber parts are our maily products. Also free samples for your reference is also ok for us. We not only help you to solve the problem when producing, but also offer some packing, assembly service to save your cost in your local.

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. Good quality 20mm Carbon Fiber Plate - 2mm 6mm 10mm uav carbon fiber sheet/plate/board – Feimoshi , The product will supply to all over the world, such as: Lyon, Seattle, Belize, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.