Good quality Carbon Fiber Square Pipe - Customize DIY carbon fiber drone tube – Feimoshi

Good quality Carbon Fiber Square Pipe - Customize DIY carbon fiber drone tube – Feimoshi Detail:

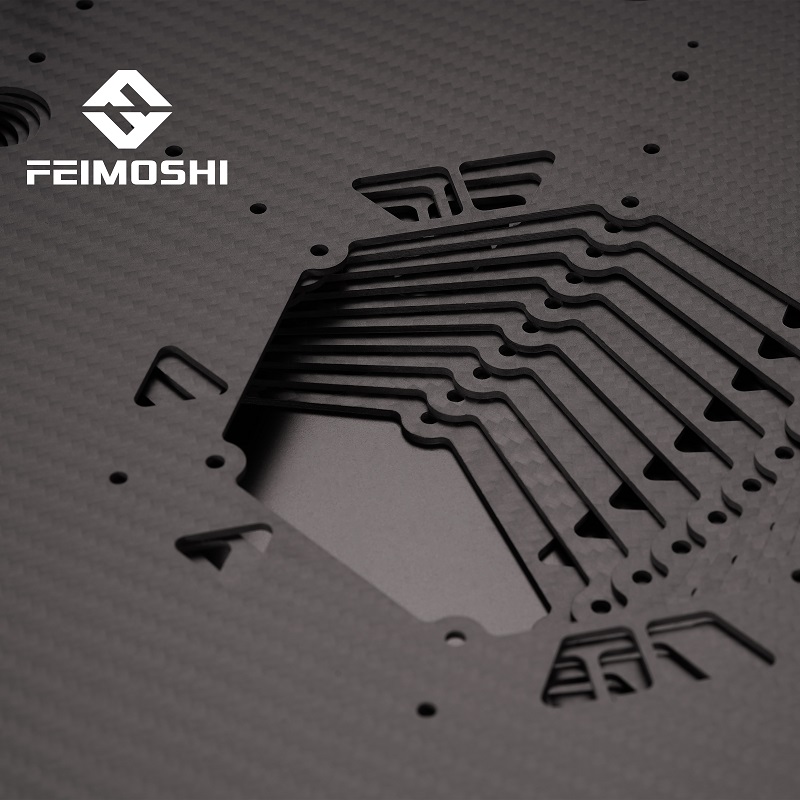

Shape: Customize DIY carbon fiber drone tube

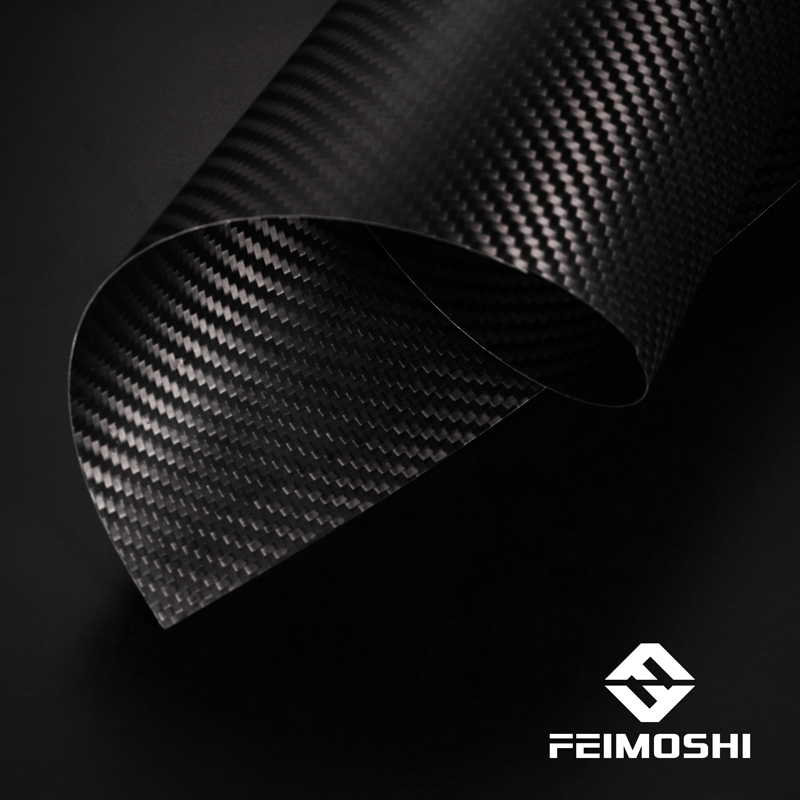

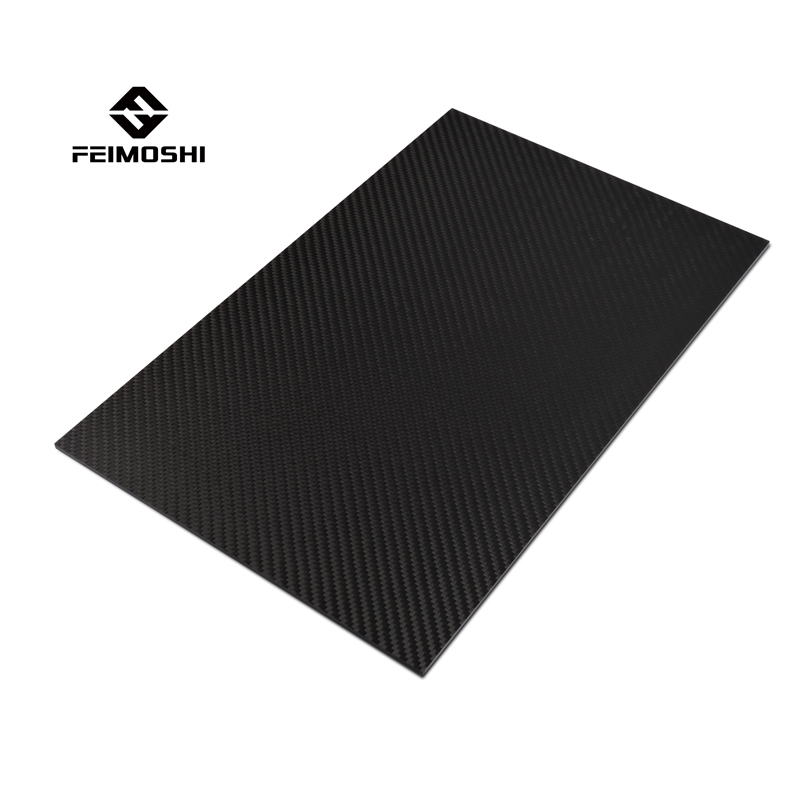

Raw Materials: Toray T300 3K twill matte Carbon Fiber

Performance: High-Strength and Light-Weight

Supply Type: In-Stock Items(Various size and different length)

Material: 100% Carbon Fiber/Full carbon fiber

Weight: 0.1-1kg

Feature: Abrasion-Resistant, Waterproof, Anti-Static

Thinckness: 1.0mm/1.5mm/2.0mm/3.0mm….10.0mm/20.0mm/30.0mm

Length: Longest Length Is 2000mm

Payment Type: T/T,Paypal,Western Union

Appearance: 3K twill weave, plain weave, or other

Finish: Glossy, matt, natural Techniques: Rolling-wrapping Advantage: High-Strength, light weight, Corrosion Resistant etc.

Recently, we have Octagon carbon fiber tube, round carbon fiber boom, curved carbon fiber tube and square carbon fiber tube in stock. These moulds are made by us. We could do

Looking for ideal Carbon Fiber Bicycle Tubing Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Diy Carbon Fiber Tubing are quality guaranteed. We are China Origin Factory of Flexible Carbon Fiber Tubing. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

2. Low thermal expansion coefficient. A low coefficient of expansion is beneficial for improving the accuracy of the company's products. Good quality Carbon Fiber Square Pipe - Customize DIY carbon fiber drone tube – Feimoshi , The product will supply to all over the world, such as: Nepal, Vancouver, Grenada, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.