Good Quality Composite Boom - 0.5mm 2.0mm thick CNC cutting 3K carbon fiber rc parts – Feimoshi

Good Quality Composite Boom - 0.5mm 2.0mm thick CNC cutting 3K carbon fiber rc parts – Feimoshi Detail:

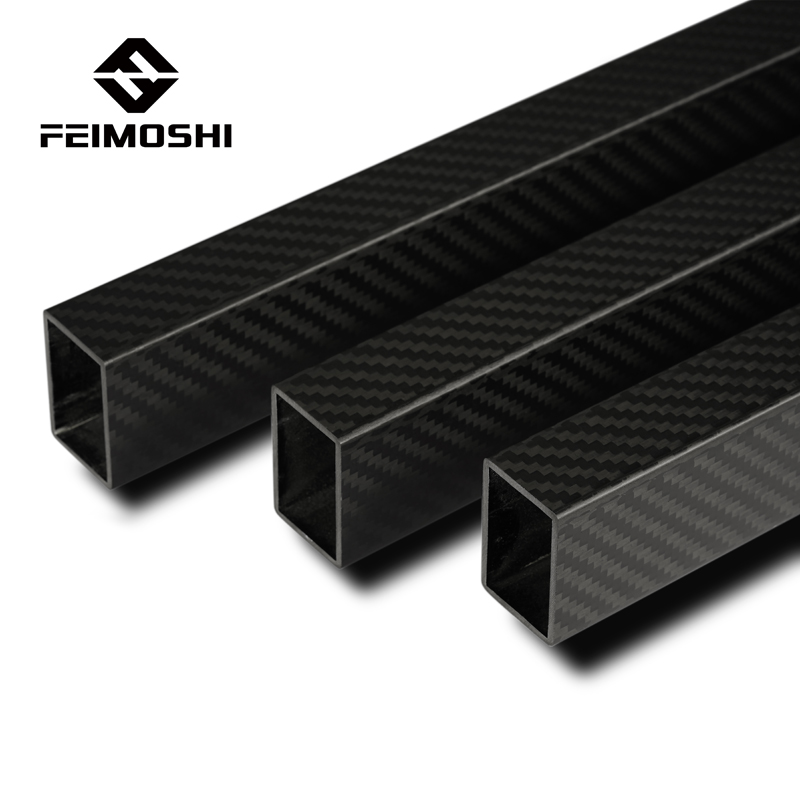

0.5mm 2.0mm thick CNC cutting 3K carbon fiber rc parts

CNC Cutting is our specialiity. We could offer CNC Carbon Fiber Cutting frames which are cutout from kinds of Carbon Fiber Sheets.

While the most popular one is 3K 100% full Carbon Fiber CNC Cutting frames. Smooth cutting, countersinking, chamfering are available with high precision according to your requirements. Both Silk screen pringting and Inlay logo are offered. Confidentiality is as important as quality. About the 3k twill matte Carbon Fiber Sheet,it is stronger and lighter. Normally we have the thickness from 0.3mm to 30.0mm,especially we are strong in the field of Cnc Carbon Fiber Cutting Service. CNC carbon fiber customized cutting is possible to process complex surfaces that are difficult to be machined by conventional methods, and can even process some unobservable parts. We support CNC Carbon Fiber Cutting, carbon fiber tube drilling, shaped carbon fiber and Logo Service.

We are strong in the field of CNC cutting,welcome to inquiry.

FAQ

1) Do you offer the carbon fiber cutting?

Yes, please send me the drawings by dxf, dwg or step format.

2)800X1000mm plate could be cut?

Yes, large plate cutting is ok for us.

3)What is the production time?

Normally, about 10-15 working days for cutting.

4) which size plate do you have in stock?

400X500mm and 500X600mm, other size needs to be customized.

5) What is the tolerance of carbon fiber plate and cutting?

Plate tolerance: +/-0.1mm-0.2mm

Cutting tolerance: +/-0.1mm-0.2mm

Looking for ideal Carbon Fiber Sheet 7mm 8mm Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 0.5mm Thickness Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of 0.75mm Thickness Carbon Fiber Sheet. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Chopped carbon fiber has high strength, high modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, good electromagnetic shielding, and does not swell or swell in organic solvents, acids and alkalis. Excellent corrosion resistance. Good Quality Composite Boom - 0.5mm 2.0mm thick CNC cutting 3K carbon fiber rc parts – Feimoshi , The product will supply to all over the world, such as: UK, Paraguay, Rwanda, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.