High Quality Composite Tube - high quality 3k full carbon fiber round tube – Feimoshi

High Quality Composite Tube - high quality 3k full carbon fiber round tube – Feimoshi Detail:

Product Description

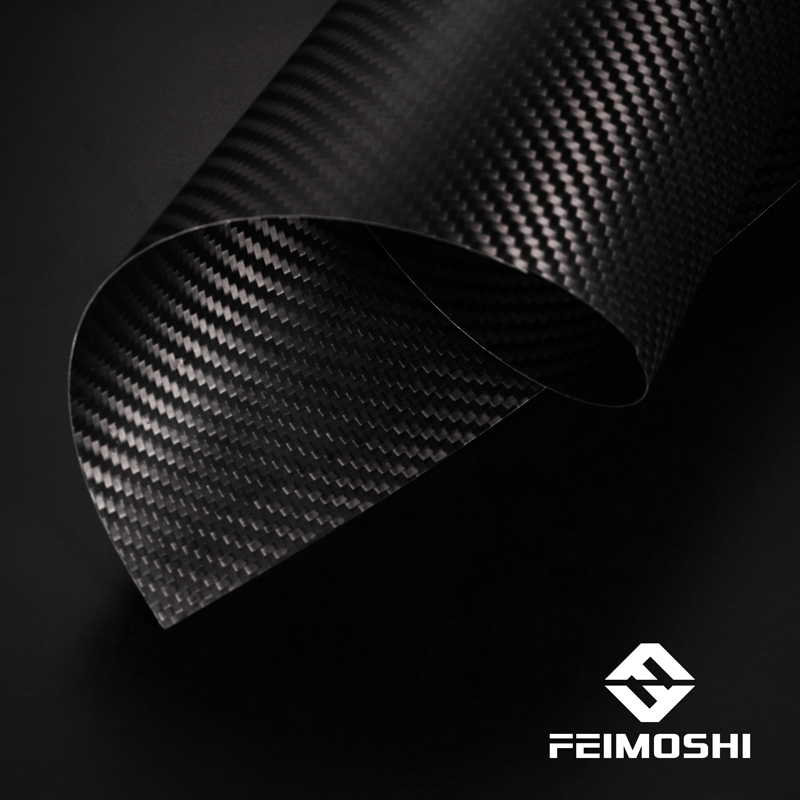

Carbon fiber tube is composed of Carbon Fiber Twill (or Plain) Weave Fabric, Unidirectional Carbon

Fiber prepreg and epoxy resin. The tube is firstly table rolled with a mandrel of certain diameter and length.

Then put into the oven of high temperature for thermoset process. To reach high precision,

the tubes are usually ground and then put onto the epoxy spray if Glossy shinny finish needed.

Surface Finish: Glossy and Matte

Application: Aviation, models, vehicle modification and metal machine parts processing.

The main size and specifications: Fiber Specifications:1K,3K

Weaving Style: Plain. Twill

Fiber Type: Carbon fiber+carbon fiber, Carbon fiber+ glass fiber, Carbon fiber+aramid fiber

Thickness: Specific thickness can be met according to customer needs)

Service:CNC Customized Hardware.Logo service.CNC Cutting Service And Logo Printing

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. High Quality Composite Tube - high quality 3k full carbon fiber round tube – Feimoshi , The product will supply to all over the world, such as: Panama, Kuala Lumpur, Provence, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.