High Quality Composite Tube - Real pure 3K carbon fiber tube From FMS composite material – Feimoshi

High Quality Composite Tube - Real pure 3K carbon fiber tube From FMS composite material – Feimoshi Detail:

Real pure 3K carbon fiber tube From FMS composite material

1.Carbon fiber round tube

2.Carbon fiber tapered tube

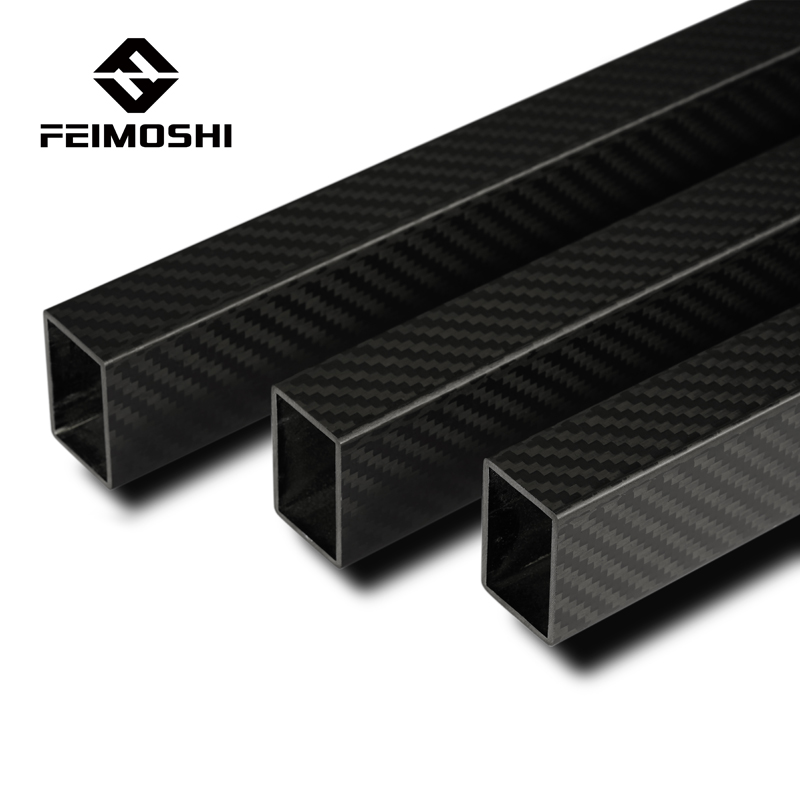

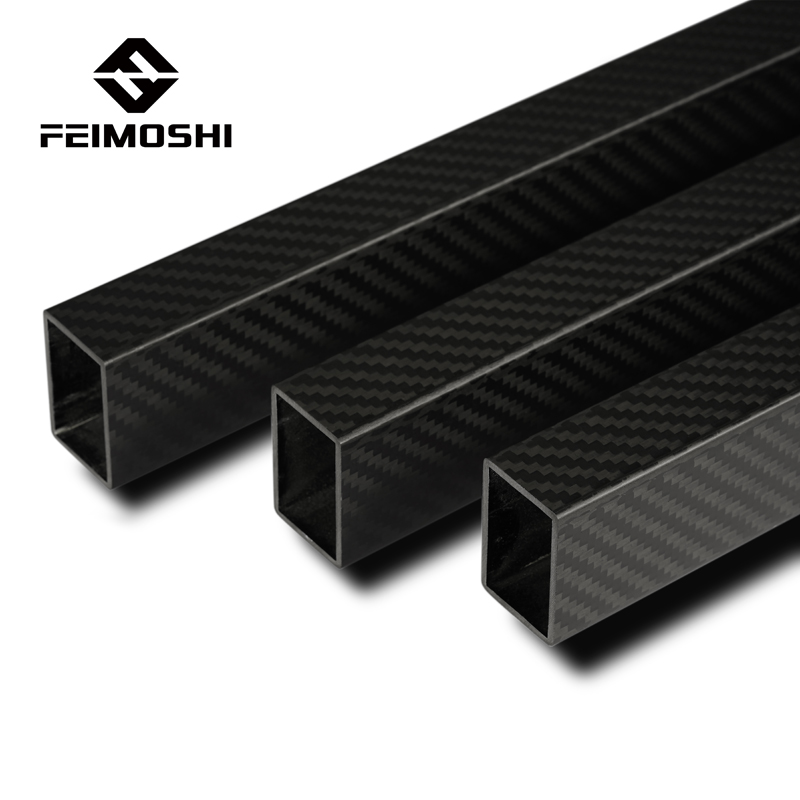

3.Carbon fiber square tube

4.Carbon fiber rectangle tube

5.Carbon fiber triangle tube

6.Carbon fiber hexagon tube

7.Carbon fiber octagonal tube

Roll wrapped prepreg carbon fiber tubes are constructed using multiple wraps of twill and/or unidirectional fabrics. It’s ideal for applications that require high strength and light weight. Carbon fiber tubes/poles are widely used in different applications like telescopic poles, sport equipment, exhaust pipes and etc.

Material: Carbon fiber and resin.

Surface: Glossy or matte finish, plain or twill weave pattern, black UD surface.

Dimension: Customized dimension. Maximun length could be 2 meters.

Features: Light weight; High strength; High modulus; Fatigue resistance; Corrosion resistance; High Electric Conductivity

Application: Aerospace, Construction, Wind power, Marine, Automobile decoration, Sports equipment, Medical equipment.

Our Advantages:

10 years experience

Professional manufacturer

Strict Quality Control

Expert workers

Close Tolerance

Reasonable price

Short Production Time

Company Culture&Value

We also support CNC cutting service, add chamfer, countersunk to make your carbon fiber cutting parts more special without barreling.

FAQ

Q1.Can I have a sample?

A: We welcome customers to take samples and check the quality and accept mixed samples.

Q2. Can i send you CAD drawings or 3D drawings, and then you make samples for me to test?

A:Yes, we can make the products you need according to CAD drawings or 3D drawings. CAD drawings can be provided in dxf/dwg format, 3D drawings can be provided in step/iges/x-t format.

Q3. Can I visit the factory?

A: Very welcome! Our factory is located in Guangdong Province, and we will show you around our factory.

Q4. what services can we provide?

A: Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,HKD,CNY ,EUR;

Accepted Payment Type: T/T,L/C,D/P, D/A,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese.

Product detail pictures:

Related Product Guide:

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. High Quality Composite Tube - Real pure 3K carbon fiber tube From FMS composite material – Feimoshi , The product will supply to all over the world, such as: Japan, Morocco, Lisbon, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.