Hot-selling Carbon Fiber Mount - Carbon Fiber Texture Phone Cover Aramid Fiber Mobile Phone Case For Iphone 13 / mini / Pro / Pro max – Feimoshi

Hot-selling Carbon Fiber Mount - Carbon Fiber Texture Phone Cover Aramid Fiber Mobile Phone Case For Iphone 13 / mini / Pro / Pro max – Feimoshi Detail:

Carbon Fiber Texture Phone Cover Aramid Fiber Mobile Phone Case For Iphone 13 / mini / Pro / Pro max

Features :

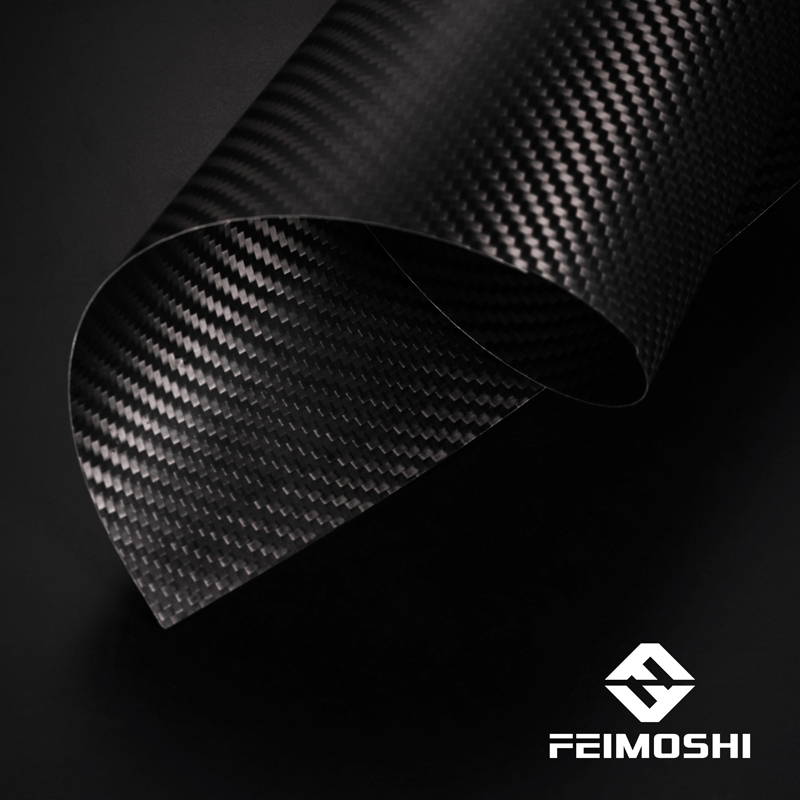

1,made of 100% aramid, a high-tech luxury material for body armor, aero space, supercars.

2.Weightless feel. Weight less than 9G. One of the lightest case on the planet.

3.Extremely Thin. A slim profile of 0.7mm only.

4.Extraordinary scratch resistant, grippy but non-slippy coating

5.Ridiculously durable and incredibly strong. 5 times stronger than steel at the same weight.

6.Our secret process for vacuum forming technology ensures the cases are perfectly formed to the phone size.

Easily and naturally access all buttons and ports. Each opening is not only accurately aligned, but also at natural “surface

level”.

7.No interference to WIFI, GPS, Apple Pay, Wireless charging or your signals.

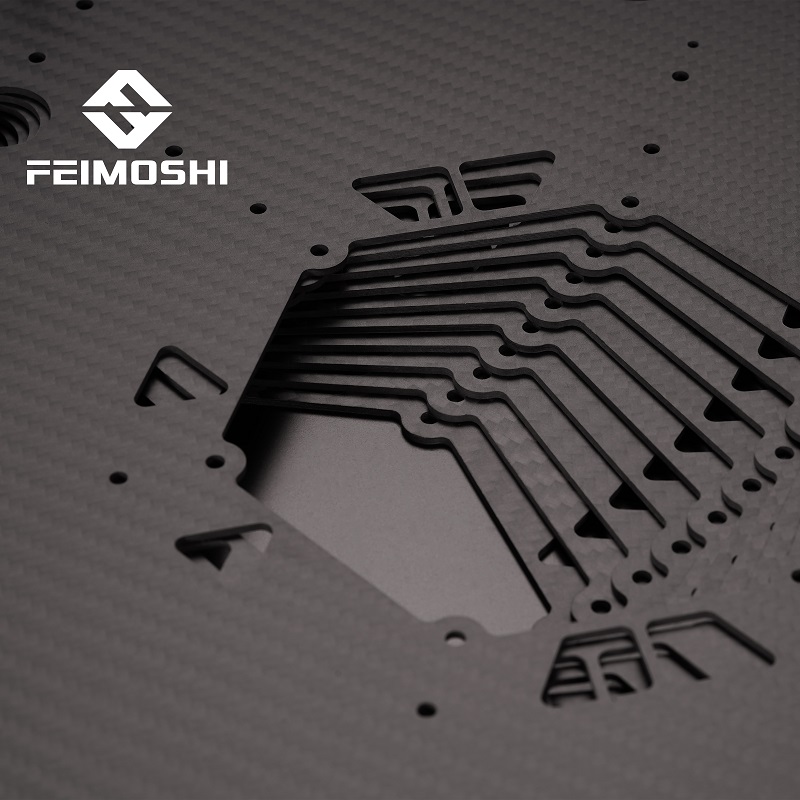

Product detail pictures:

Related Product Guide:

At this stage, many product parts are made of carbon fiber. Most parts are not standard plate and tube products. In the application environment, there are some inclination and shape regulations. Carbon fiber composite materials have good ductility, and epoxy resin can complete various intricate shapes in the flow of the mold. At this stage, the customized industry has a very large demand for such special-shaped parts. Some customers do not understand the basic knowledge of the production and application of carbon fiber special-shaped parts. Hot-selling Carbon Fiber Mount - Carbon Fiber Texture Phone Cover Aramid Fiber Mobile Phone Case For Iphone 13 / mini / Pro / Pro max – Feimoshi , The product will supply to all over the world, such as: Sydney, El Salvador, Colombia, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.