Manufacturer for Forged Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi

Manufacturer for Forged Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi Detail:

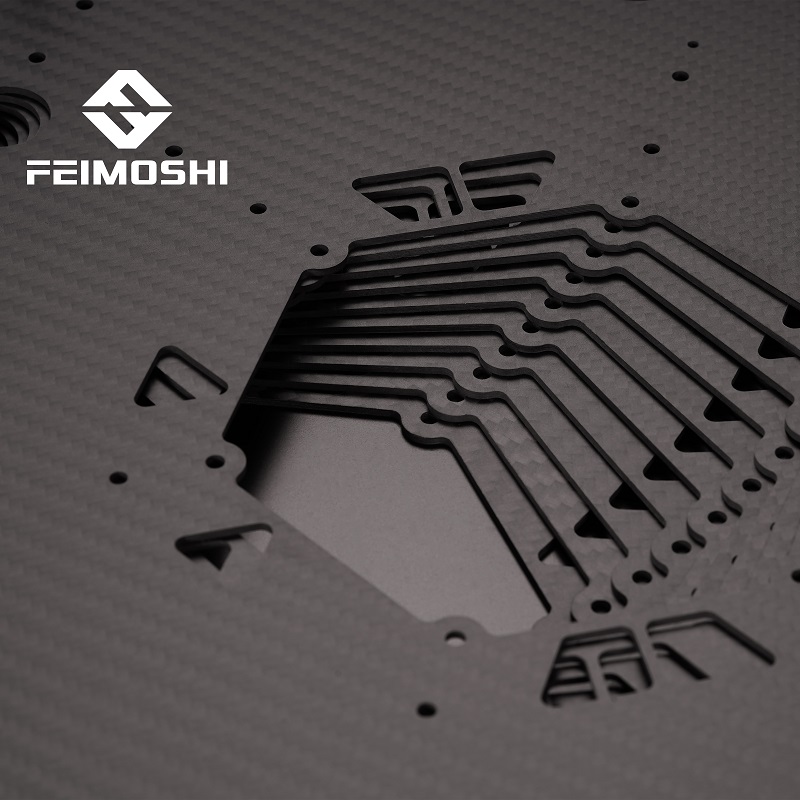

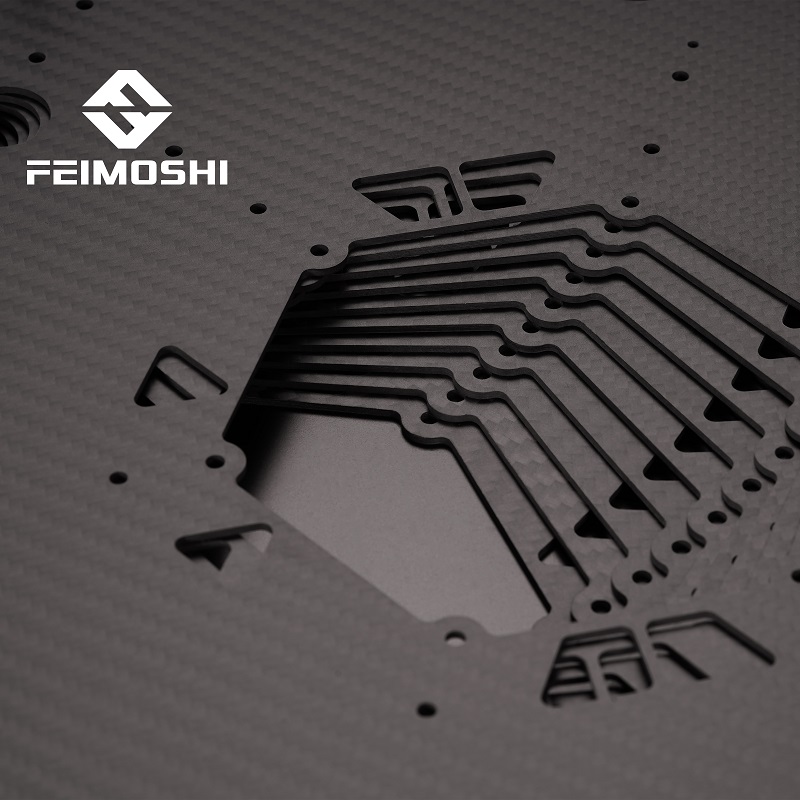

OEM service custom carbon fiber cnc cutting

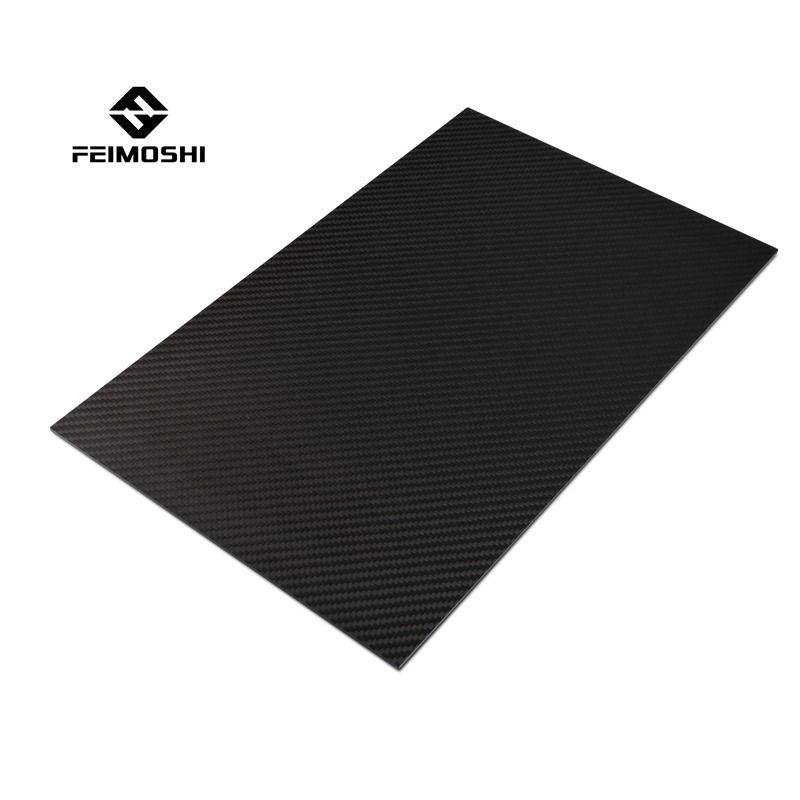

Carbon fiber plates come in so many variations to fit a wide range of applications. A standard carbon fiber plate is an excellent replacement for aluminum plates when you need something lightweight and strong.

Carbon fiber plate comes in thicknesses from 0.040” (1mm) up to 1.00” (25.4mm) to fit nearly any application. Standard twill and plain weave plates are excellent choices for replacing aluminum or steel.

Material: carbon fiber frame part

Size: Customized (welcome to customized)

Surface: Twill/Plain Matte/Glossy or other colors

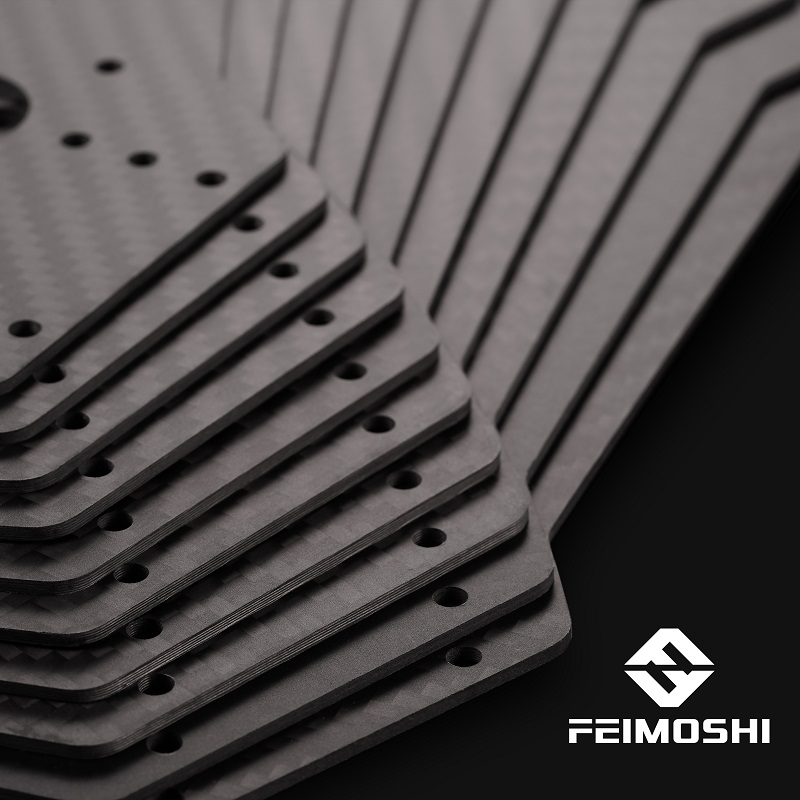

Stock: Normal plates are in stock

Service: OEM & ODM, Cnc Cutting Service, And Logo Printing

Other Service: Packing and assembly service

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is the Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for tesing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Manufacturer for Forged Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi , The product will supply to all over the world, such as: Zurich, Greece, Macedonia, The surface of the wound carbon fiber prepreg must be coated with a layer of OPP, and then the wound carbon fiber tube is sent to a high-temperature curing furnace to dry and form, and finally the mold is released, and the unstable parts on both sides are cut off to carry out production and processing solutions.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly