OEM Factory for Carbon Fiber Paddle - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi

OEM Factory for Carbon Fiber Paddle - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi Detail:

Lightweight phone case carbon fiber shockproof and anti-drop

Below is the newest iPhone 13 cases:

1. Material: Kevlar Fiber

2. Technology: Vacuum Pumping by Autoclave equipment

3. Weight: as light as you thought

4. MOQ: 10pc

5. Matte surface, no sweats, no fingerprints;

6. 4-side protection, camera lens protection;

7. Excellent grip, no loose;

8. 1:1 precise cutouts for ports and buttons;

9. Like a skin, keep the original beauty/feeling of the device

Why do we use aramid fiber, but don’t use carbon fiber?

Aramid fiber is commonly used in aerospace and performance automotive industries, as it is exceptionally durable and lightweight.

Different from carbon fiber, aramid fiber does not affect your phone’s signal (Wi-Fi, GPS, and cell reception), making it the ideal material for phone cases.

Using vacuum forming technologies, we can mold aramid fiber into a multitude of designs while maintaining its strength and protective qualities.

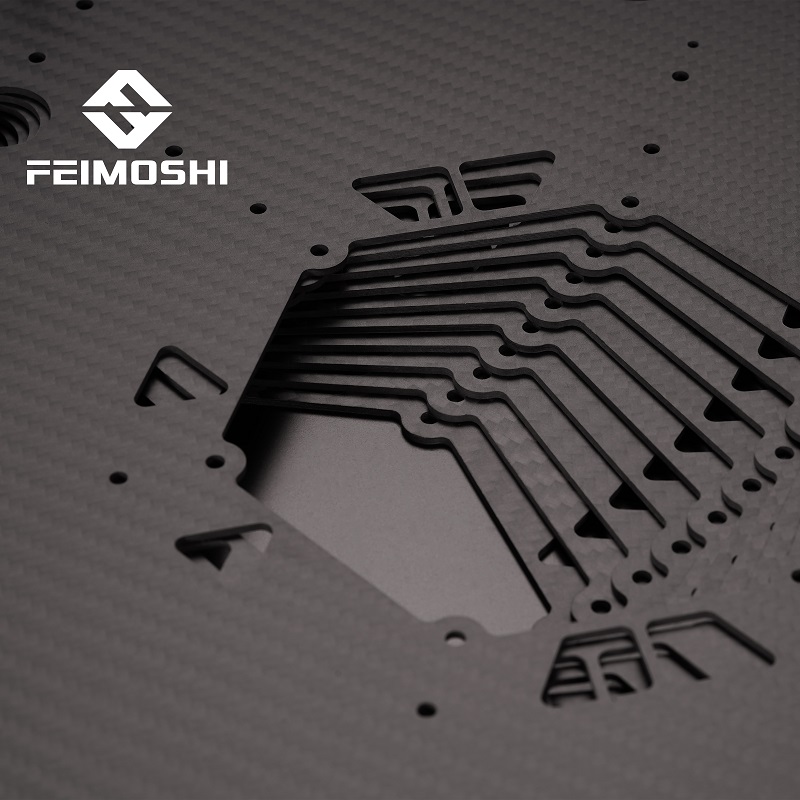

Product detail pictures:

Related Product Guide:

Carbon fiber board is a kind of multi-functional composite material with high strength, light weight and versatility. In a variety of industries, the weight strength of carbon fiber provides significant performance advantages. No matter the application, FMScarbon can provide a carbon fiber sheet to suit your needs. OEM Factory for Carbon Fiber Paddle - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi , The product will supply to all over the world, such as: Atlanta, venezuela, Sheffield, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!