OEM manufacturer Carbon Fiber Monopod - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi

OEM manufacturer Carbon Fiber Monopod - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi Detail:

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Protective Cases – aramid Bullet-Proof Material – Wireless Charging Capable – Slim, Drop Protection – Textured, Non-Scratch Shell

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

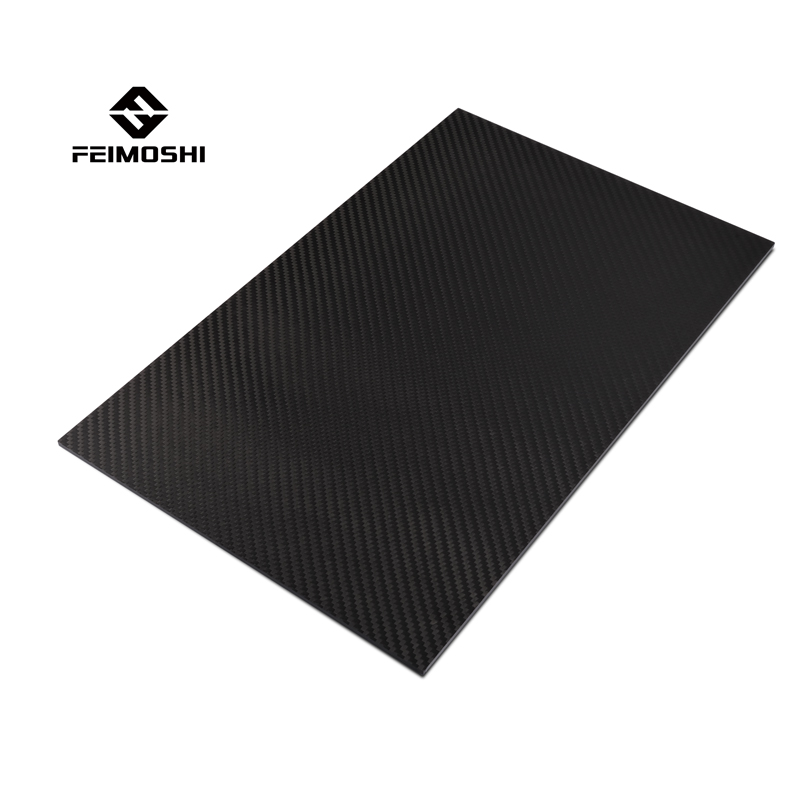

Product detail pictures:

Related Product Guide:

At this stage, many product parts are made of carbon fiber. Most parts are not standard plate and tube products. In the application environment, there are some inclination and shape regulations. Carbon fiber composite materials have good ductility, and epoxy resin can complete various intricate shapes in the flow of the mold. At this stage, the customized industry has a very large demand for such special-shaped parts. Some customers do not understand the basic knowledge of the production and application of carbon fiber special-shaped parts. OEM manufacturer Carbon Fiber Monopod - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi , The product will supply to all over the world, such as: Madagascar, Lesotho, belarus, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Send your message to us:

Write your message here and send it to us