OEM/ODM China Composite Frame - 3K carbon fiber CNC cutting parts – Feimoshi

OEM/ODM China Composite Frame - 3K carbon fiber CNC cutting parts – Feimoshi Detail:

3K Carbon Fiber CNC Cutting parts

Have you designed your own frame and are looking to have it cut?

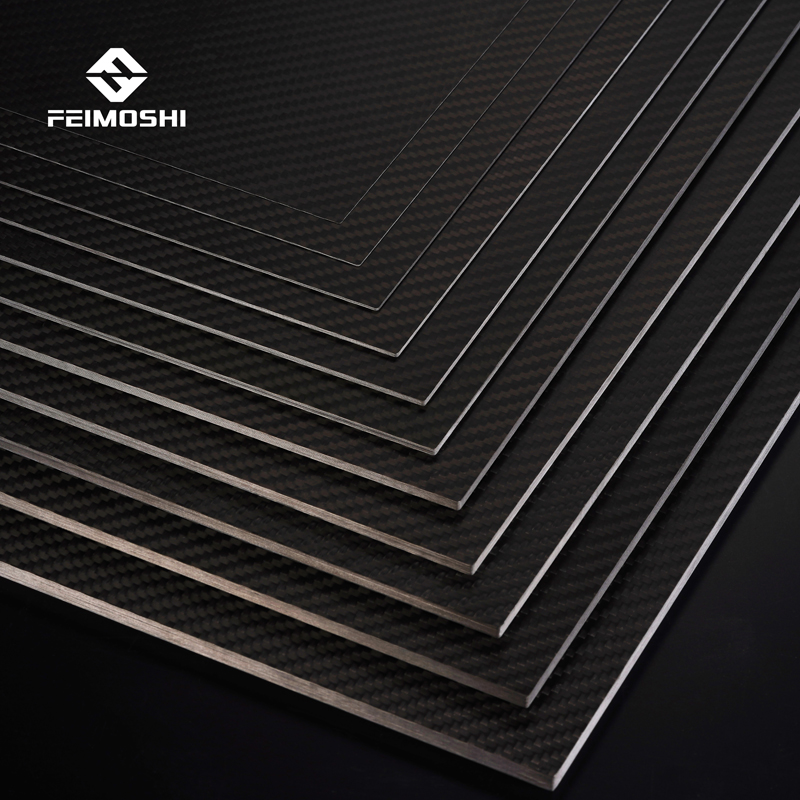

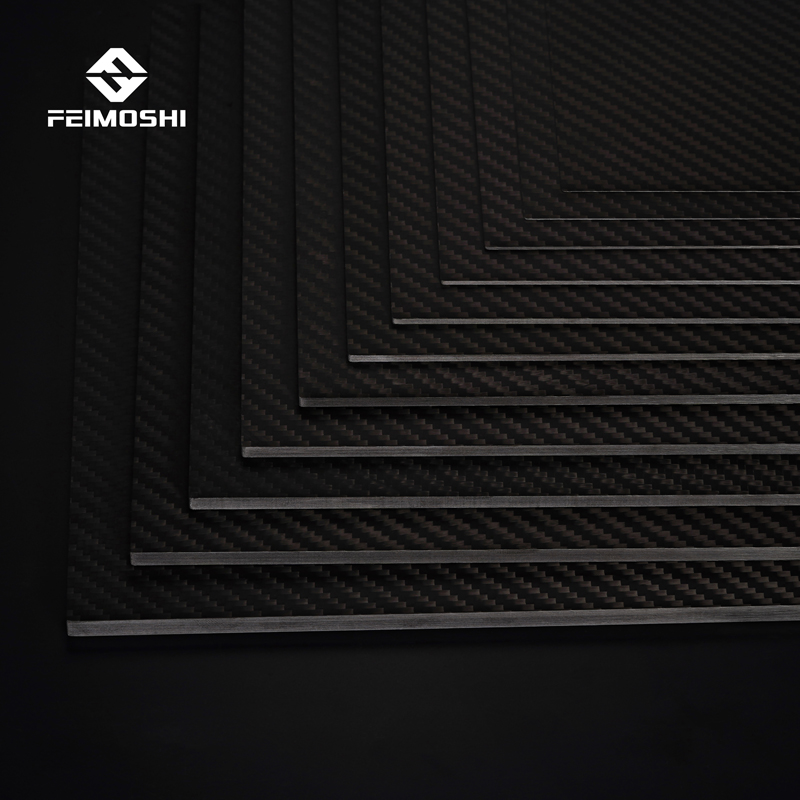

We can turn it into a reality for you. We carry high quality 3K Twill, Matte Finish Carbon Fiber Plates in .5, 1, 1.5, 2, 2.5, 3, 4 & 5mm thickness (up to 500 X 600mm). We can also special order other sizes and types of finishes. All Carbon Fiber edges are lightly wet sanded to clean them up after cutting.

We support CNC Carbon Fiber Cutting, shaped carbon fiber part, customized carbon fiber tube( curved carbon fiber tube, Octagon carbon fiber boom) and Logo Service.

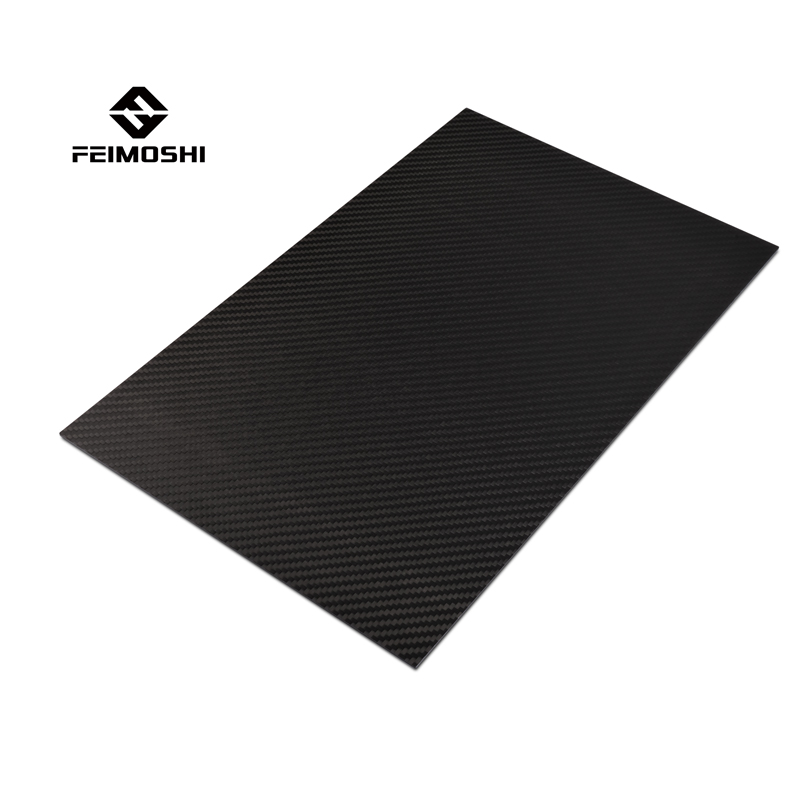

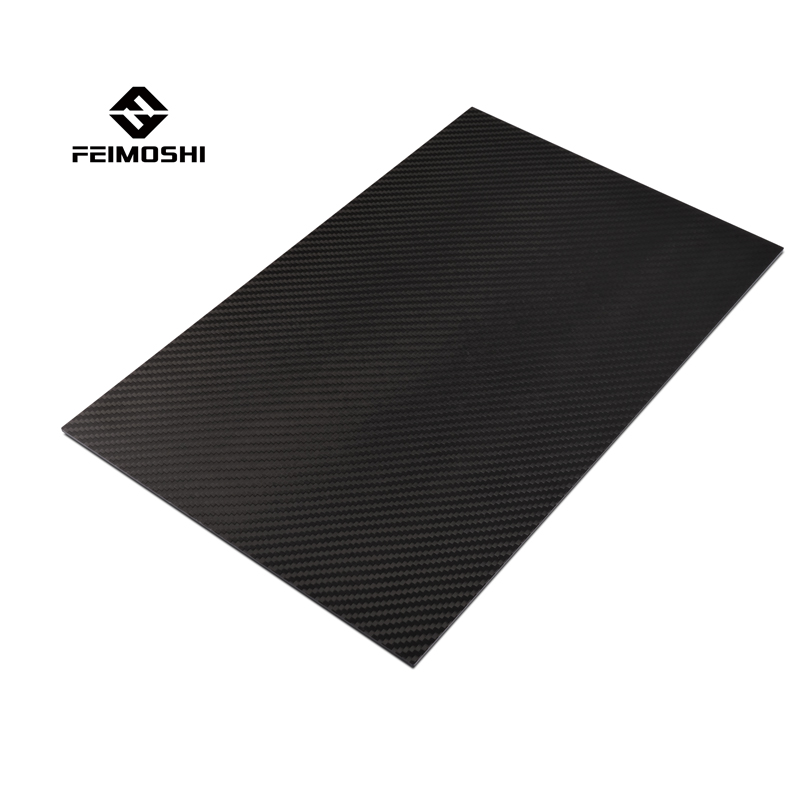

Material: full carbon fiber plates sheets

Size: 400x500mm, 500X600mm, 600X800mm, 800X1000mm or other customized size

Surface: 3K/1K twill/Plain matt/Glossy

Stock: twill matte 0.5-10.0mm full carbon plates in stock

Service: OEM & ODM and CNC cutting services

Our service

* Drawings, photos and samples are welcome.

* We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

* We are looking forward to have a good cooperation with you.

* Welcome to Hobby Carbon!

FAQ

Q:1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q: 2. What is the lead time?

A:Sample needs 1-3 days, mass production needs 10-15 days, also according to the order volume.

Q: 3. Do you have any MOQ limit?

A: Our MOQ is 200pcs for both formal raw material and processing parts.

Q: 4. Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc

Q: 5. How do you ship the goods and how long does it take arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Looking for ideal Carbon 3K Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the CNC Cutting Parts are quality guaranteed. We are China Origin Factory of Carbon Fiber CNC. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

At present, the carbon fiber industry is in a period of explosive growth, and the growth rate of the carbon fiber demand market will remain at around 17% in the future. OEM/ODM China Composite Frame - 3K carbon fiber CNC cutting parts – Feimoshi , The product will supply to all over the world, such as: Brazil, Iceland, United Kingdom, Carbon Fiber Forming: Carbon fiber sheets made of epoxy glue are not thermoset (thermoformable) - the finished sheet cannot be heated and bent to maintain the bent shape. Carbon fiber laminate does not stretch easily like plastic. You can get very insufficient permanent index of refraction in an orientation above high fever, but because of this difficulty, we do not strongly recommend the application. Molded pieces are possible, but the carbon fiber fabric must be stored in the mold and the epoxy glue introduced prior to the heating/drying process.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!